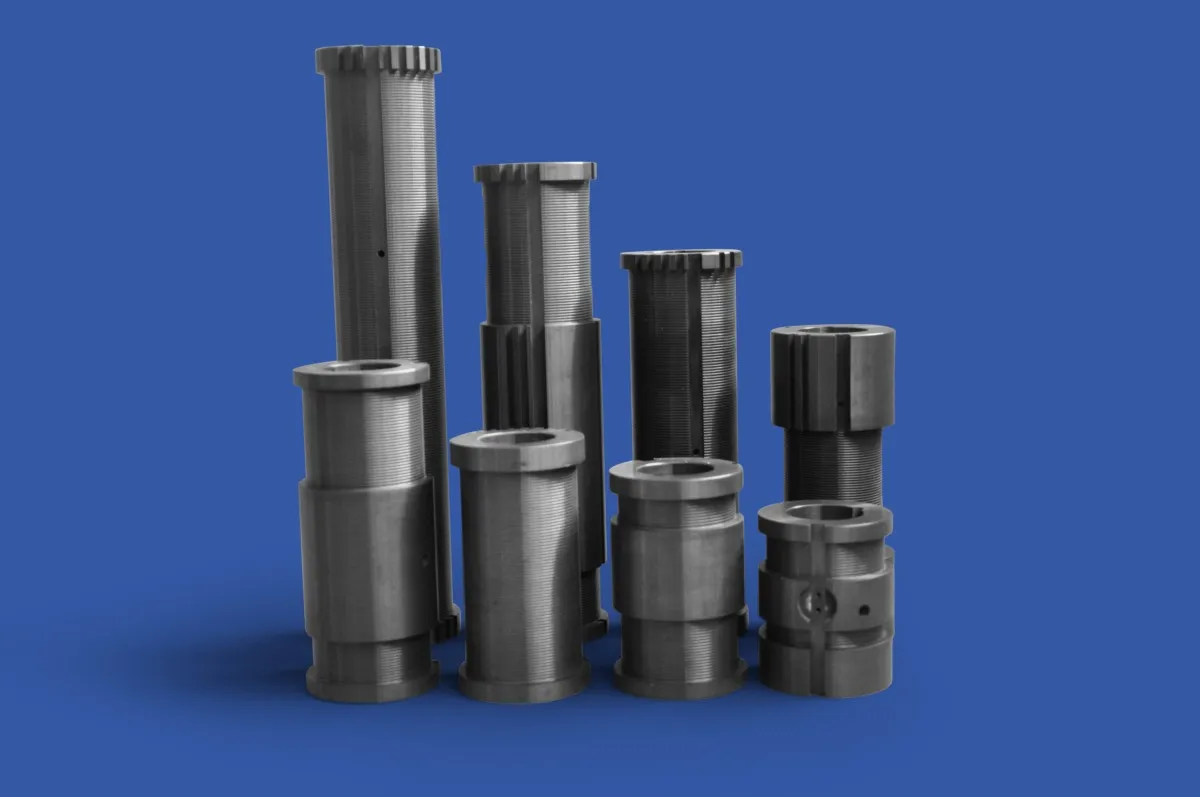

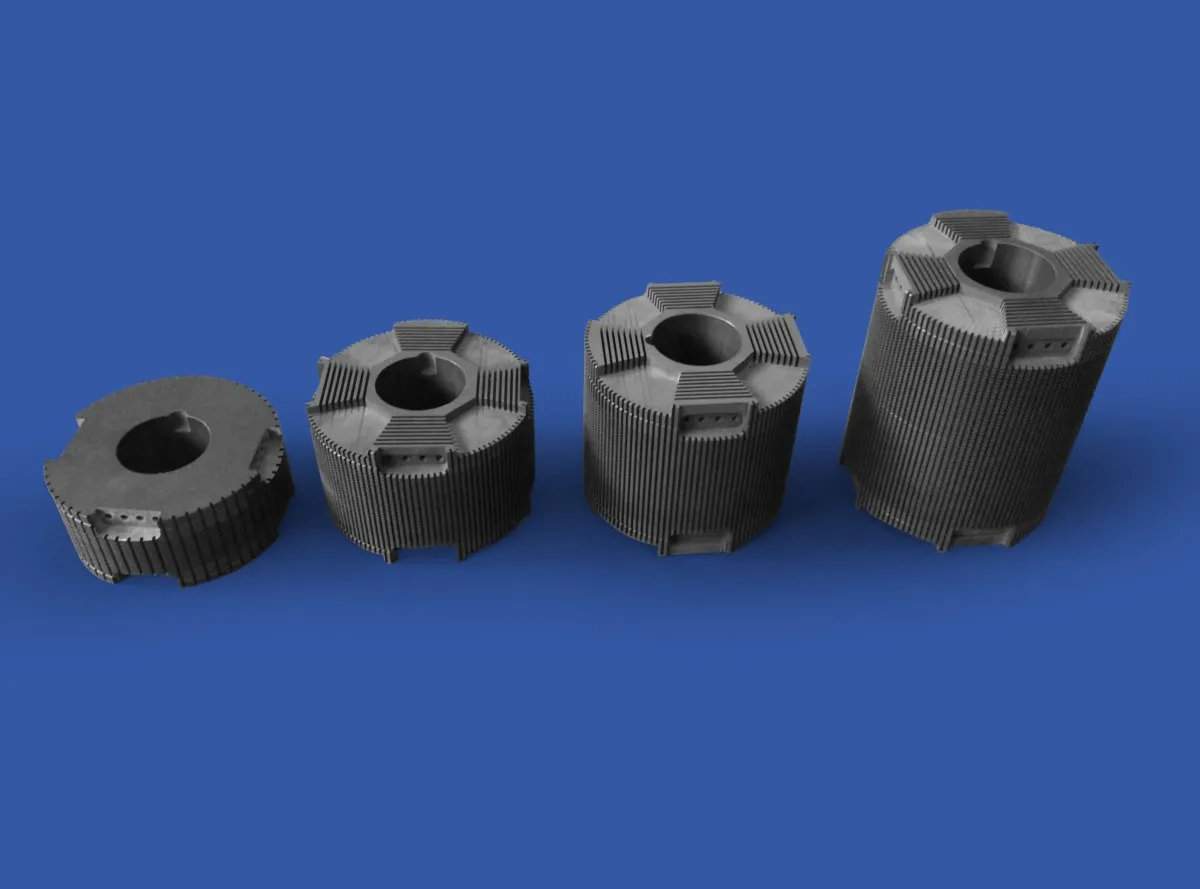

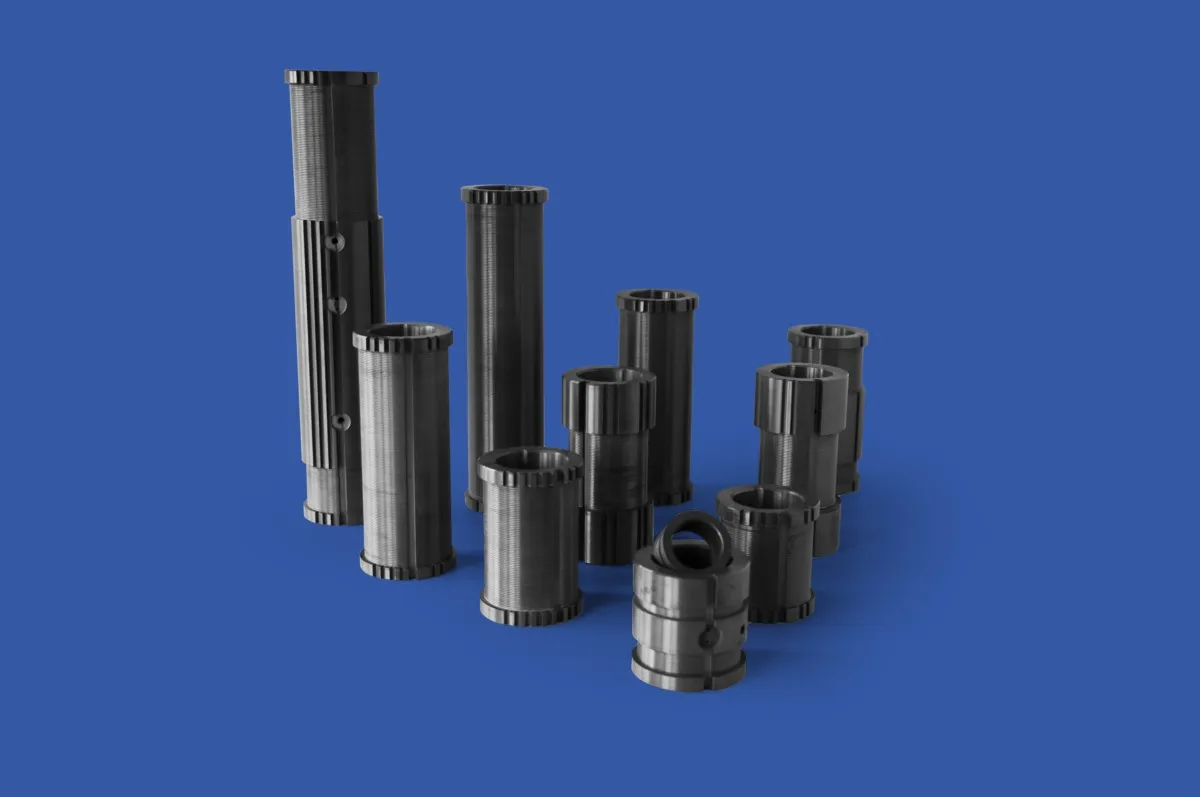

As the coil rack of the sensor coil, the silicon nitride coil rack mainly applies the ultra-high hardness performance of silicon nitride ceramics and the nonmagnetic insulation of Silicon Nitride (Si3N4) Ceramic. As the sensor coil rack, it must be insulated and nonmagnetic in order to accurately transmit the collected data; At the same time, as a sensor for depth exploration, the underground environment is generally complex, and only the support with high hardness can protect the sensor from damage. In addition, the silicon nitride support has certain protective effects on the sensor coil due to its anti-corrosion, high and low temperature resistance, and low coefficient of thermal expansion.

Applications:

Induction ceramic coil of induction instrument in practical oil well logging instruments

In the field of medical imaging equipment, such as magnetic resonance imaging (MRI) systems, gradient coil stents are used as core components

Silicon Nitride Ceramic Material Properties

| Properties | Unit | Value |

| Density | g/cm3 | 3.2±0.05 |

| Relative density | % | >99.5 |

| Elastic Modulus | GPa | 300~320 |

| Crushing Load Ratio (25℃) | % | ≥40 |

| Hardness | (HRA) | 91 |

| Fracture Toughness | MPa·m1/2 | 6.0~7.0 |

| Flexural Strength | MPa | 600~700 |

| Poisson’s Ratio | – | 0.25 |

| Coefficient of Thermal Expansion | 10-6 /K | 2.3~3.2 |

| Weibo Modulus | Gpa | 10~12 |

| Thermal Conductivity | – | 15~20 |

| Resistivity | W/(m·K) | 1018 |

| Acid and Alkali Corrosion Resistance | – | Excellent |

| Dimensional Stability | – | Excellent |

| Magnetism | – | None |

| Oxide Content | % | 8 |

Benefits:

High strength over a large temperature range

High fracture toughness

Good flexural strength

Mechanical fatigue and creep resistant

Lightweight – Low density

High hardness and wear resistance, both impingement and frictional modes

Superior thermal shock resistance

Low thermal expansion

Electrical insulator

Good oxidation resistance

Good chemical corrosion resistance

Wear-resistant

Enquiry

Enquiry