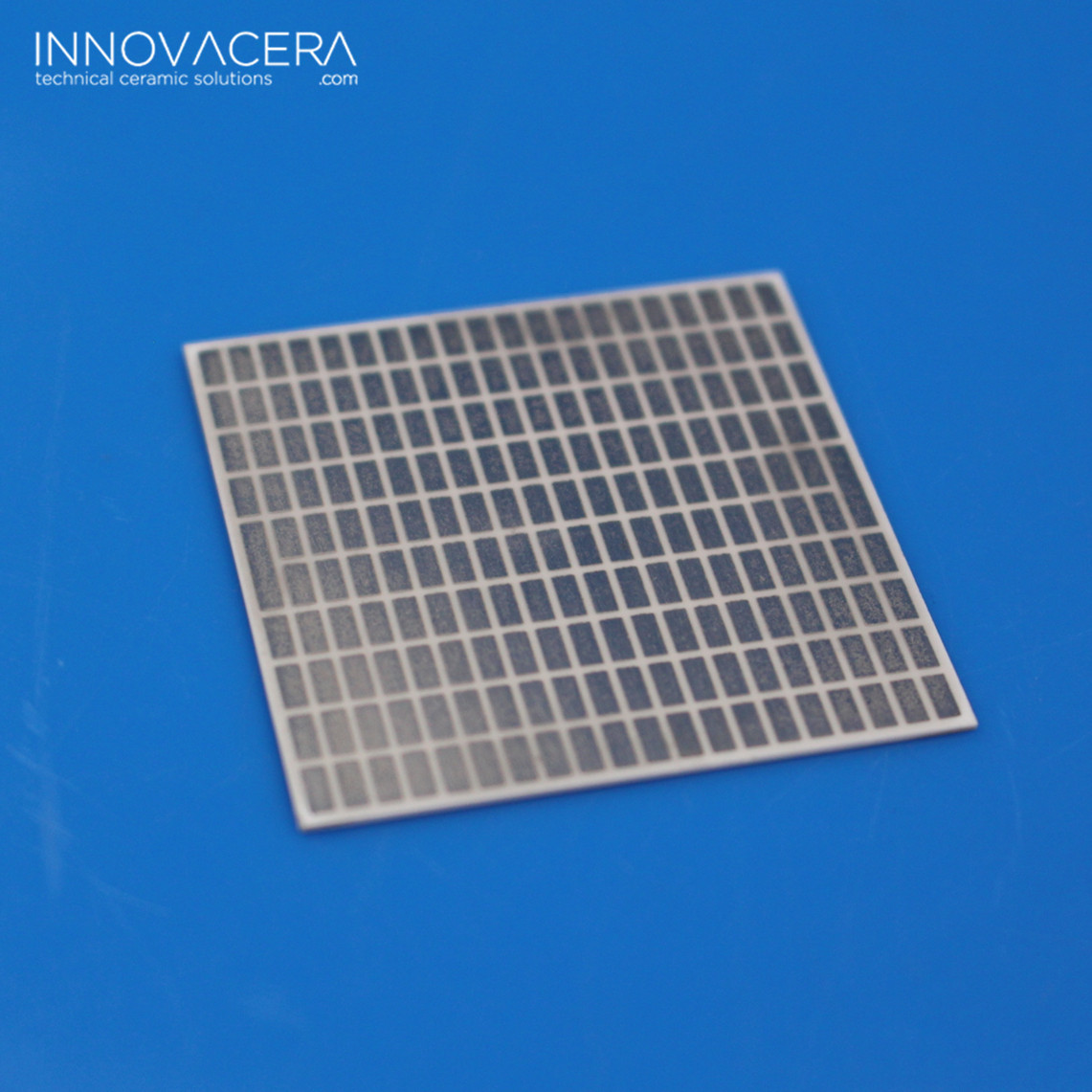

At present, high-performance aluminum nitride ceramic plates are used as thermal conductive substrates in advanced packaging processes, and copper is directly bonded on aluminum nitride to further design circuits, surface mount transistors, and power diodes. Due to its good thermal and electrical properties, AlN has gradually become the preferred material for this type of substrate design and can be used as insulating substrates for high-power devices, heat dissipation substrates for VLSI and packaging substrates, etc.

Advantages Of AlN Ceramic Materials Used As Copper Clad Substrate Materials

Aluminum nitride copper-clad laminate has the thermal conductivity and mechanical strength of aluminum nitride, as well as the thermal conductivity and electrical conductivity of copper, so it has great application potential in the aerospace field. In addition, the “copper-aluminum nitride-copper” sandwich structure can play a key role in the modularization and integration of electronic systems, serving as mechanical support, electrical isolation, and heat dissipation paths for power modules. It is worth noting that in the application of aluminum nitride copper clad laminate, the interface bonding between AlN and Cu is very important, and the interface phase determines the bonding force between the ceramic and the metal copper layer. The conventional preparation process of aluminum nitride copper-clad laminate includes the hot pressing method and the direct copper cladding method (DBC).

The hot pressing method requires sputtering a metal layer on the surface of AlN by magnetron sputtering and then introducing copper sheets for hot pressing. The DBC method requires pre-oxidation of AlN ceramics and Cu sheets, and then heat treatment to bond. The peel strength of the substrate prepared by the DBC method is about 4 times that of the hot pressing method, and Cu and AlN can form a stronger bonding force, which has better application prospects in the aerospace field with harsh service environments.

Enquiry

Enquiry