Unlike single-function devices made by traditional manufacturing techniques, Micro Electro Mechanical Systems (MEMS) is a micro-sized controllable electromechanical device system that integrates micro-mechanical structures, sensors, actuators, and electronic components. This type of product has numerous advantages, including small size, light weight, low cost, low power consumption, high reliability, mass producibility, easy integration, and intelligent implementation. This also means that encapsulation not only needs to protect the internal microelectronic components from external impurities, but also provides a stable and controllable physical environment for the internal structure. Different types of MEMS products all have their own unique manufacturing processes and specific packaging forms. Ceramic packages, due to its excellent airtightness, outstanding thermal-mechanical properties, insulation, and thermal stability, generally offers better comprehensive performance in providing long-term reliability protection compared to metal or plastic packaging.

Commonly used ceramic packaging materials and characteristics

Aluminum oxide (Al₂O₃): Low cost, excellent insulation properties, commonly used in sensor substrates and packaging casings.

This is the most widely used and technologically mature ceramic packaging material. Its advantages lie in its excellent comprehensive performance and relatively low manufacturing cost. Its high resistivity (up to 10¹⁴ Ω·cm) and high dielectric strength also ensure excellent electrical insulation properties. However, its thermal conductivity is relatively lower than that of aluminum nitride, and it is not suitable for scenarios with extremely high power density.

Aluminum Nitride (AlN): High thermal conductivity, suitable for heat dissipation packaging of high-power MEMS devices.

Its thermal conductivity can reach 170–200 W/m·K, which is several times higher than that of alumina. Meanwhile, its thermal expansion coefficient is very close to that of silicon chips. This can significantly reduce the thermal stress generated by the package on the chip when the temperature changes, thereby enhancing the lifespan and stability of the device in harsh temperature environments. Therefore, it is commonly found in the packaging of high-power LEDs, lidar systems, high-performance computing chips, and tactical-level MEMS sensors.

Silicon nitride (Si₃N₄): High strength and chemical resistance, suitable for MEMS in harsh environments.

The advantage lies in its outstanding comprehensive mechanical properties, especially its extremely high fracture toughness and bending strength, which can provide unparalleled shock and vibration protection for sensitive MEMS structures. However, its manufacturing cost is higher than that of alumina. It is usually applied in scenarios that have extremely high requirements for reliability and mechanical strength, rather than in cost-sensitive consumer electronics.

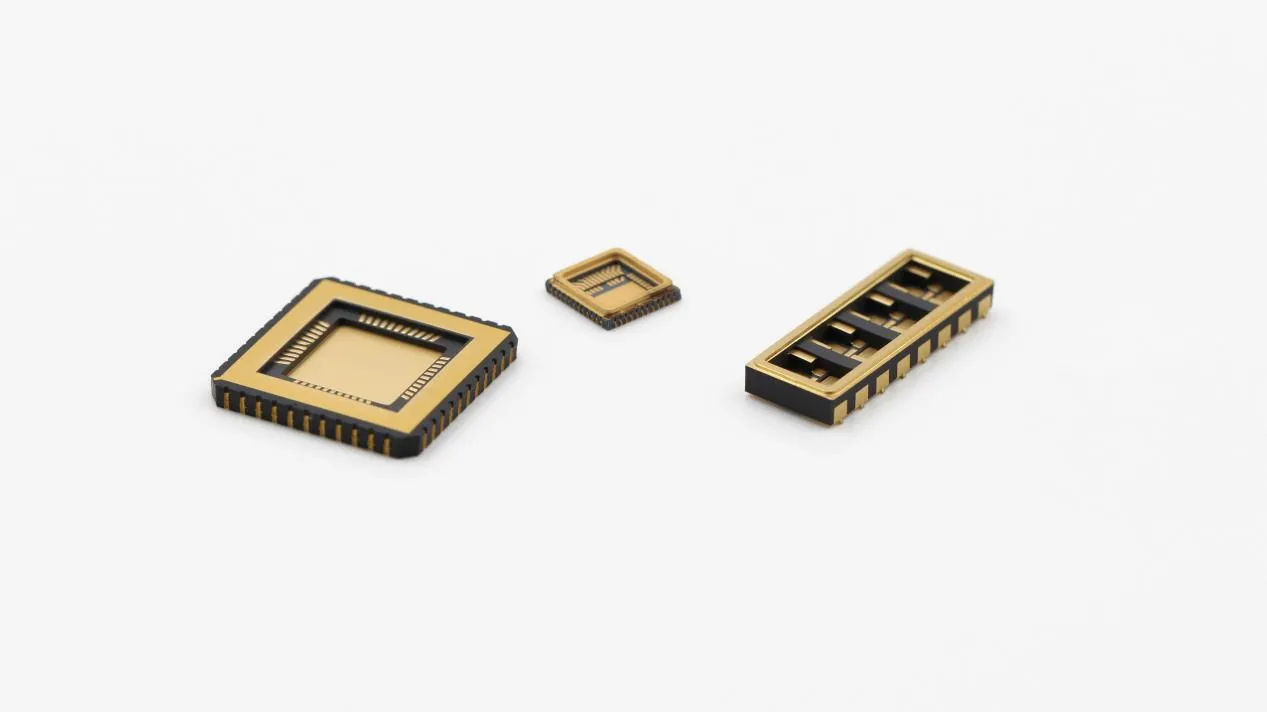

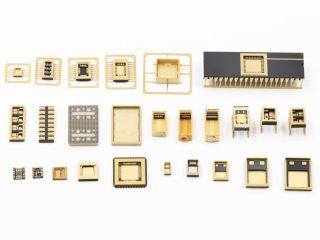

Forms and processes of ceramic packaging

Co-fired ceramics (LTCC/HTCC): Suitable for mass production and capable of integrated wiring.

This process combines multiple layers of raw porcelain with metal circuits and conducts a high-temperature co-firing operation at one time, resulting in an airtight assembly containing complex three-dimensional interconnection structures. It not only facilitates mass production to reduce costs, but also enables high-density wiring and the embedding of passive components (resistors, capacitors, inductors), thereby enhancing the integration and miniaturization level of MEMS devices.

Hermetic packaging: Based on a ceramic substrate, it achieves long-term stability through metallization and glass brazing/laser welding.

This structure is the key to ensuring the long-term reliability of MEMS devices (such as gyroscopes, resonators). It undergoes metallization treatment on a ceramic substrate to form a sealing ring, which is then fused with the cover plate using glass brazing or laser welding, creating an internal inert or vacuum environment that can isolate moisture and contaminants, ensuring the stable performance of sensitive microstructures over long-term use.

Microchannel ceramic packaging: Integrated channel design for fluid MEMS and gas sensors.

Utilizing precision processing techniques such as laser ablation and solution coating stacking, microfluidic channels are directly manufactured within the ceramic substrate. This encapsulation process is essential for realizing functional MEMS devices such as microfluidic controllers, biochips, and gas sensors, as it enables controlled interaction between the working fluid and the sensing chip.

Application Examples

1. MEMS Gyroscope and Accelerometer: Used in aerospace and autonomous driving

The inertial sensor requires the internal micro-mass block to move in a vacuum environment to avoid the influence of air damping on the signal sensitivity, thereby achieving extremely high detection accuracy. The ceramic gas seal ensures the long-term stability of the internal vacuum environment and is the lifeline that guarantees its high precision and reliability.

2. MEMS Pressure Sensor: Used in automotive engine compartments and oil well monitoring

In extreme environments such as high temperature, high pressure, and corrosive media, ceramic packaging can serve as a mechanical isolation layer, preventing external stress from directly acting on the sensitive silicon chips. At the same time, its corrosion-resistant property enables it to come into direct contact with harsh media, which ensures the accuracy of the signal output.

3. RF MEMS Switches and Filters: For 5G/6G Communications and Radar Systems

These devices are extremely sensitive to high-frequency signals and require a stable working environment. Improper packaging can seriously degrade the Q value and insertion loss of the devices. Ceramic packaging (such as LTCC) offers low-loss transmission paths, excellent thermal management capabilities, and enables the embedding of multiple passive components (such as inductors and capacitors) onto the substrate, facilitating the miniaturization of system-level packaging.

Ceramic packaging in MEMS systems is far from being merely a simple protective shell. It plays a crucial role in ensuring the long-term stability and reliability of the devices in harsh environments, and can create a high-quality internal environment for MEMS devices to survive and function.

Enquiry

Enquiry