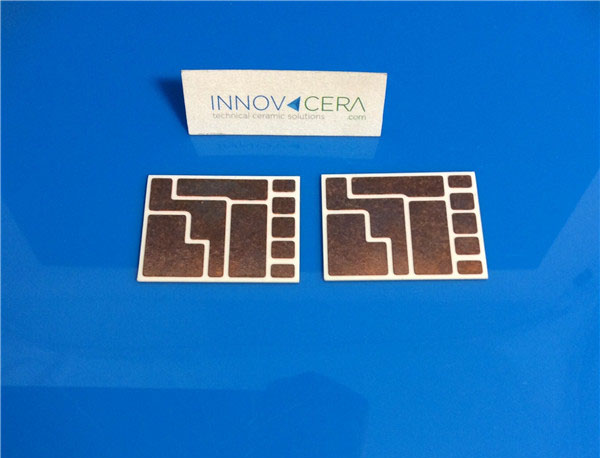

DBC (Direct Bonded Copper) substrates are composed of a ceramic insulator, Al2O3 or AlN onto which pure copper metal is attached by a high-temperature eutectic melting process and thus tightly and firmly joined to the ceramic.

DBC Ceramic Substrate Key Features:

Ceramic metallized: Ti/W, gold(Au), silver(Ag),Copper(Cu),nickel(Ni)¡Kothers & produce final circuit

Coating: 0.075um to 5mil

Ceramic Metallized substrate:

Al2O3 substrate metallized

AlN substrate metallized

Silicon wafer metallized

LED heat-dissipation ceramic substrate:

LED Al2O3 thin film substrate

LED Al2O3 thick film substrate

LED AlN thin film heat-dissipation substrate

Flip-chip substrate

The integration of the thin film, thick film, electrode plating and electroless plating processes

Application:

1. High Power LED ceramic substrate

2. Microwave (Wireless Communication & Radar)

3. Semiconductor Process Equipment

4. Solar Cell

5. Hybrid Electric Vehicles

6. Flip-chip/eutectic substrate

7. Sensor ceramic substrate

In future, the DBC ceramic substrates market will develop rapidly, driven by the demand from IGBT, automobile, CPV, aerospace and communication. The electric vehicles market will drive the DBC ceramic substrates to increase in the next ten years.

Enquiry

Enquiry