- What is a PBN heater?

PBN material refers to pyrolytic boron nitride material obtained by CVD high-temperature deposition. BN refers to cubic boron nitride, which is obtained by hot pressing.

The common thickness of PBN parts is less than or equal to 3mm due to the different acquisition processes.

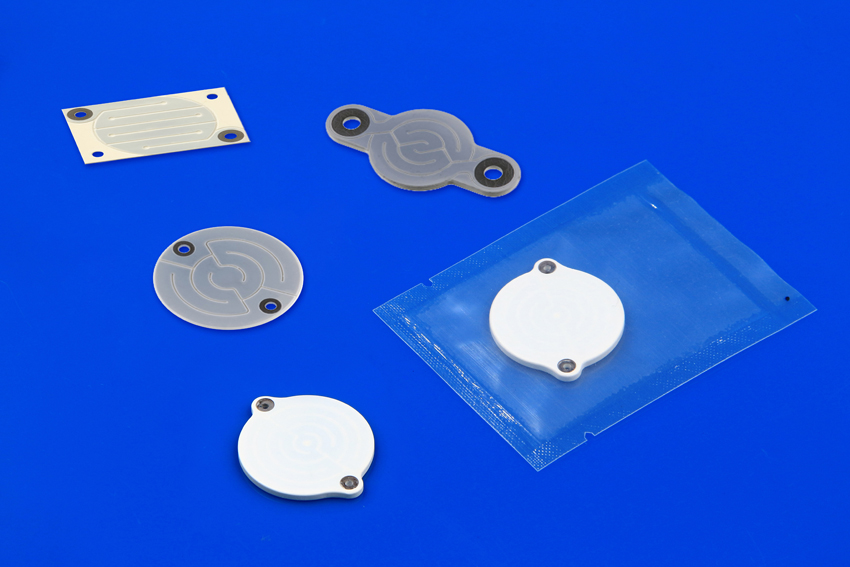

PBN heater refers to a graphite heater formed by depositing a thin layer of graphite on a PBN substrate and forming a graphite band by machining (laser engraving).

Finally, the graphite layer is covered with a layer of PBN cover layer (exposed electrode part) to become a complete graphite heater.

- How many ways are there to process?

Generally, there are two ways:

1st: PBN sheet to make a good groove, and then coated with pyrolytic graphite, add a layer of PBN coating (outside the circuit engraved by the pbn disk, deposition of pyrolytic graphite on the circuit, and then a layer of pbn deposited on the surface of the pg), the thickness of about mm, voltage and current, and then a layer of graphite.

Thickness of about 3mm or so, voltage and current according to the customer, but it should be low voltage and high current, fast heating.

2nd: graphite good trough, then trough on both sides coated with PBN, but graphite as a heating device, through the alternating current heating, will produce magnetic resonance, PBN coating is easy to fall off, so do not recommend this way of production.

So this way of production is not recommended, generally according to the first way.

Therefore, it can be seen that the substrate and the insulating covering layer are PBN, and the heat generator is graphite tape.

- Why is it manufactured in this way?

Graphite or pyrolytic graphite surface-wrapped coating, graphite is widely used in the heating field, but graphite in the vacuum and high-temperature conditions will continue to precipitate impurities, which will contaminate the ultrapure materials, the use of boron nitride non-porous, low coefficient of thermal expansion of the advantages of the graphite outer layer coated with PBN, so that the impurities precipitated by the graphite can be blocked, to protect the ultrapure materials are not contaminated. The graphite after coating is heated many times, and the surface layer of boron nitride is not easy to peel off.

- Advantage:

PBN heating pad has the advantages of chemical stability, corrosion resistance, etc., generally the highest sample heating temperature of about 1200 ℃, can work in E-5mbar oxygen atmosphere.

When working, you need to pay attention to avoid large rapid temperature rises and falls caused by the PBN cover layer and graphite layer detachment, but also pay attention to ensure that the electrodes are in good electrical contact, to avoid overheating at the contact, and damage to the electrode.

- Summarize the performance characteristics:

-Maximum temperature in vacuum 1650℃

-Maximum temperature in air 300 ℃(No recommend)

-High vacuum, extra high pressure, corrosive environment

-Very fast ramp rate, very low mass

-Very inert

-PG elements are encapsulated in PBN and are completely unaffected by deposition products

-Samples can be placed directly on the heated ceramic element plate

-Sizes up to 4″ square or round

If you need any assistance or larger heater sizes, please contact our technical sales team today. Note: Customization is possible.

Email:sales@innovacera.com

Tel:0086 0592 5589730

Enquiry

Enquiry