Mass spectrometers are a technique for analyzing and identifying chemical substances by arranging gaseous ions in electromagnetic fields based on their mass-to-charge ratios.

Mass spectrometers can detect most analytes per borehole, so it is essential to have a non-contaminating heat source. In addition, competing requirements for instrument designs to reduce size and complexity while increasing sensitivity are being challenged.

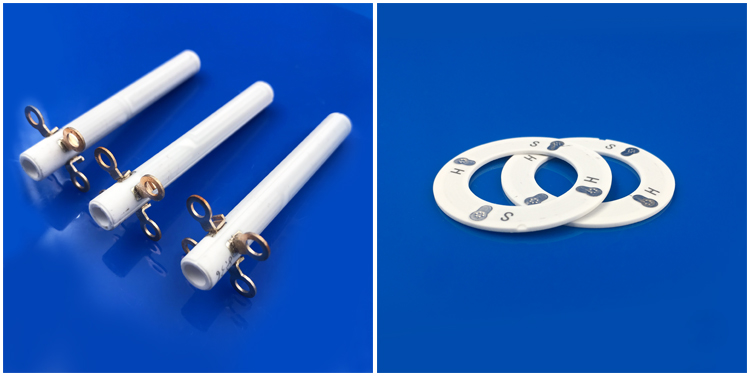

Mass spectrometer heating elements, also called source heaters or gas line heaters, are used in mass spectrometers to turn the sample (typically in an aqueous or organic solution) into a vapor for analysis. Before the analyzer and detector areas, the heaters are part of the sample conditioning system, where the vaporized sample is then bombarded by ionized high-energy electrons and analyzed.

Heaters used in mass spectrometers are compact in design and provide a fairly high power density. They are fast responding and operate at temperatures up to 400 °C. They include internal temperature sensors for accurate control and limiting.

The INNOVACERA Advantage

- Engineering Support for New Designs

- Rapid Prototyping

- Replacement Parts

Innovacera manufactures OEM and replacement heaters for a variety of mass spectrometer manufacturers and models.

Advantages of MCH heater

MCH ceramic heating element is high-efficiency, environmentally friendly, and energy-saving. ceramic heating element, which is mainly used to replace the most widely used alloy wire heating elements and PTC heating elements and components.

Technical characteristics:

- Energy-saving, high thermal efficiency, unit heat power consumption is 20-30% less than PTC;

- The surface is safe and non-charged, with good insulation performance, can withstand the voltage test of 4500V/1S, no breakdown, and leakage current <0.5mA;

- No impulse peak current; no power attenuation; rapid heating; safe, no open flame;

- Good thermal uniformity, high power density, and long service life.

Conclusion

MCH heaters have revolutionized performance by offering compact design, rapid heating, precise temperature control, and energy efficiency. These advanced heating elements enable mass spectrometers to have a non-contaminating heat source, greater accuracy and effectiveness.

If you have any questions about the MCH heater, welcome to contact us at sales@innovacera.com.

Enquiry

Enquiry