What is HTCC? It means high-temperature co-fired ceramics which is using alumina, AlN and other ceramic material to be sintering with conductor materials (Mo, W, Mo, Mn) under high temperature of 1600°C. This is first designed by RCA company by the end of the 1950s. Due to the high temperature, it can not use low melting point metal materials like gold, silver and copper, but Mo, W, Mo, Mn.

This material is low conductivity so it will lead to signal delay. So it is not suitable to make high speed or high frequency micro-assembled electric subgrade board. But the advantages of the HTCC are High structural strength, high thermal conductivity, good chemical stability, high wiring density. It has a wide application prospect in high power micro-assembly circuit.

How about LTCC? It has a lower sintering temperature lower than 900°C, using AU, Ag, Cu high conductivity low melting point metal materials could be sintering by air. It is widely used for Rf, microwave and millimetre wave devices.

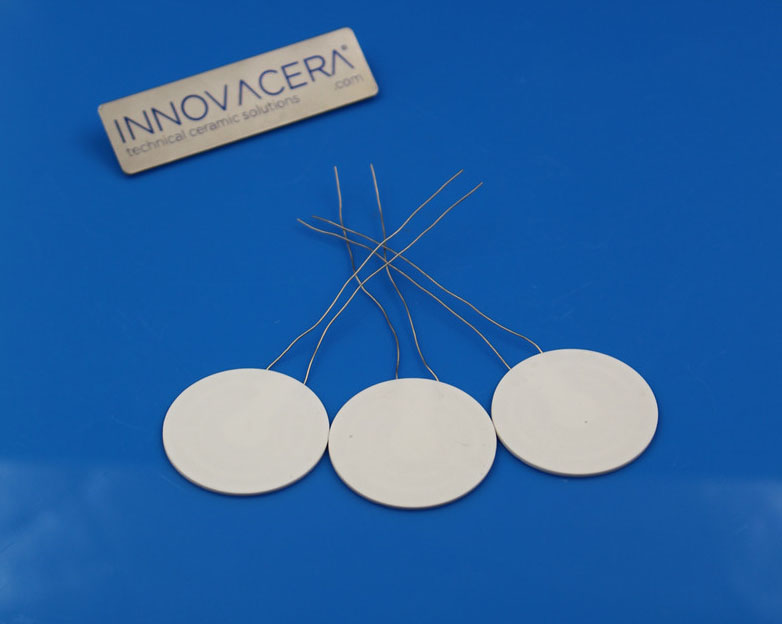

So when you choosing the ceramic material, please pay attention to what application you need so that you will know if choosing a high temperature or low-temperature ceramic. By the way, our ceramic heater belongs to HTCC.

Enquiry

Enquiry