Alumina ceramic base structural part properties:

| Item | Test Condition | Unit&Symbol | 95% Al2O3 | 99% Al2O3 | 99.7% Al2O3 |

| The main chemical ingredient | Al2O3 | Al2O3 | Al2O3 | ||

| Bulk Density | g/cm3 | 3.6 | 3.89 | 3.96 | |

| Maximum Use Temperature | 1450°C | 1600°C | 1650°C | ||

| Water absorption | % | 0 | 0 | 0 | |

| ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | 20° C | MPa (psi x 103) | 358 (52) | 550 | 550 |

| Compressive Strength | 20° C | MPa (psi x 103) | 2068 (300) | 2600(377) | 2600(377) |

| Fracture Toughness | K(I c) | Mpa m1/2 | 4 – 5 | 5.6 | 6 |

| Coefficient of thermal expansion | 25-1000° C | 1X 10-6/°C | 7.6 | 7.9 | 8.2 |

| Coefficient of thermal conductivity | 20° C | W/m °K | 16 | 30 | 30.4 |

| Thermal Shock Resistance | Tc | °C | 250 | 200 | 200 |

| Dielectricity constant | 1MHz.25°C | 9 | 9.7 | 9.7 | |

| Dielectric strength | ac-kV/mm (ac V/mil) | 8.3 (210) | 8.7 (220) | 8.7 (220) | |

| Volume Resistivity | 100°C | ohm-cm | > 10^13 | > 10^14 | > 10^14 |

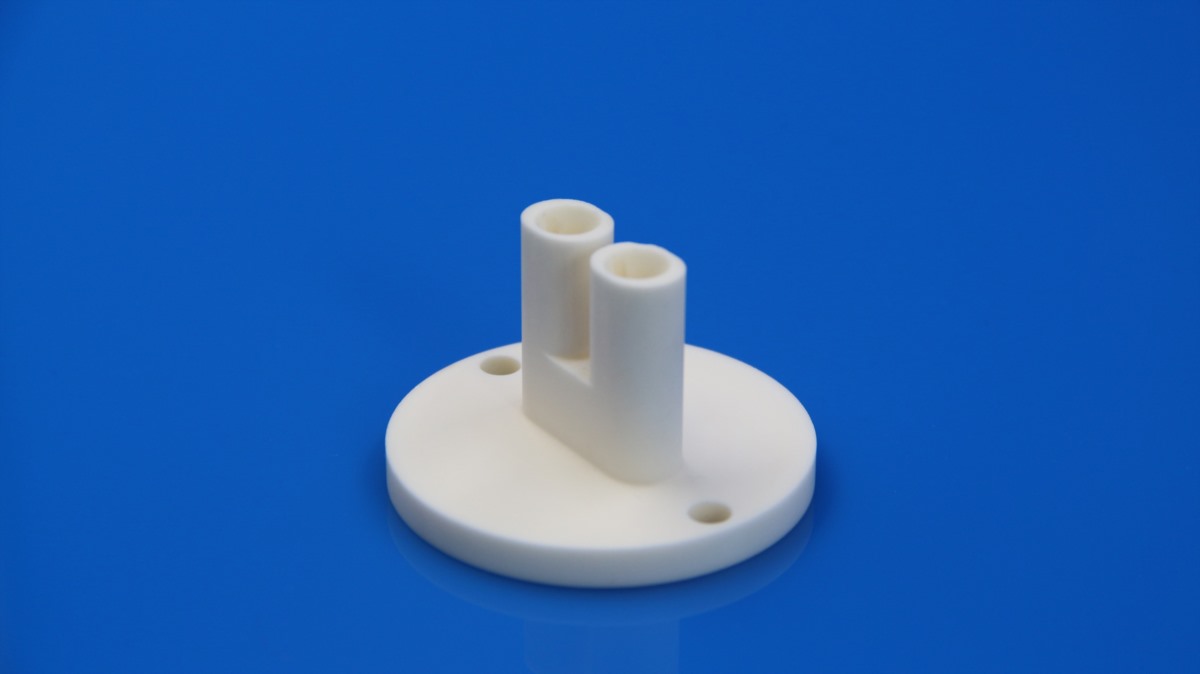

Electron generator components are crucial in semiconductor manufacturing and various high-tech applications, alumina ceramic base and nozzles are key Insulation and Shielding Components in electron generator components.

Innovacera Alumina Ceramic Parts including the Alumina Ceramic Bases have a good feedback from many semiconductor manufacturing plants. If you need any customized alumina ceramic base or other customized alumina ceramic part, welcome to contact us at sales@innovacera.com.

Enquiry

Enquiry