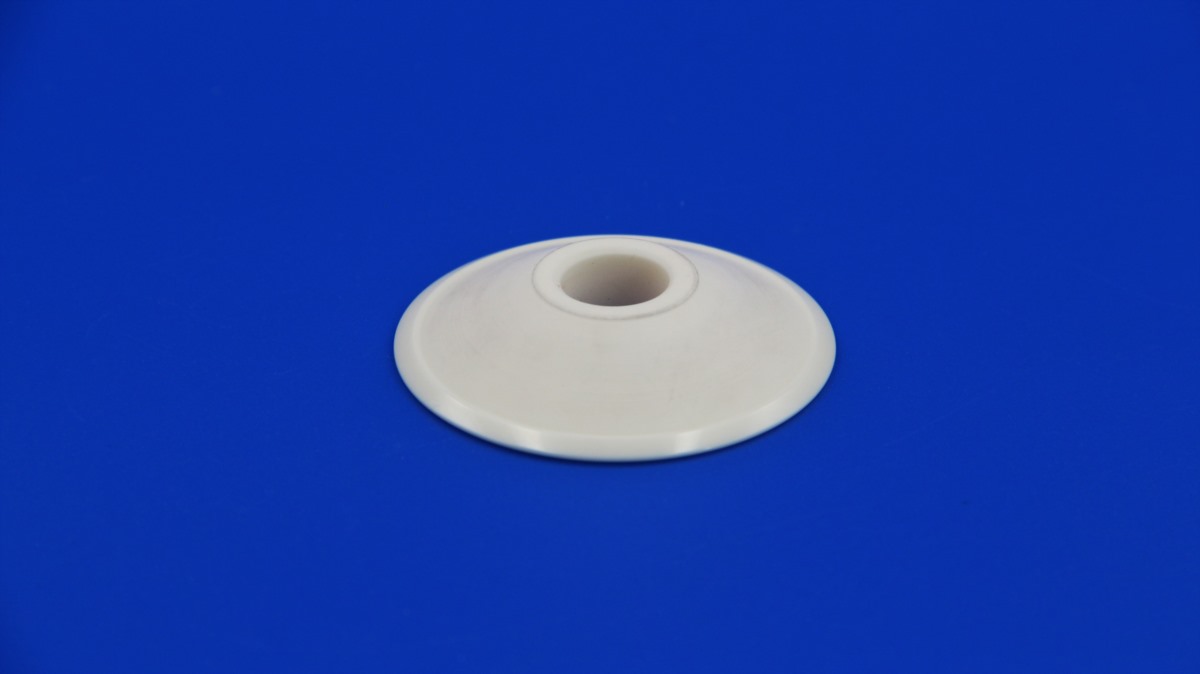

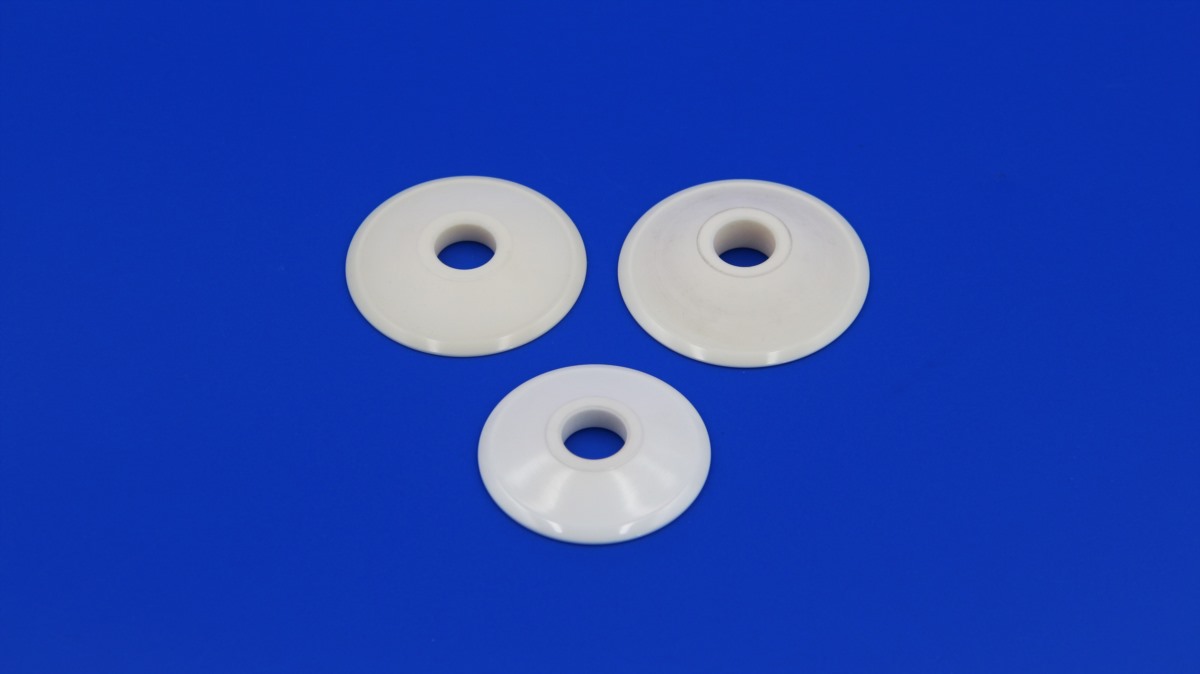

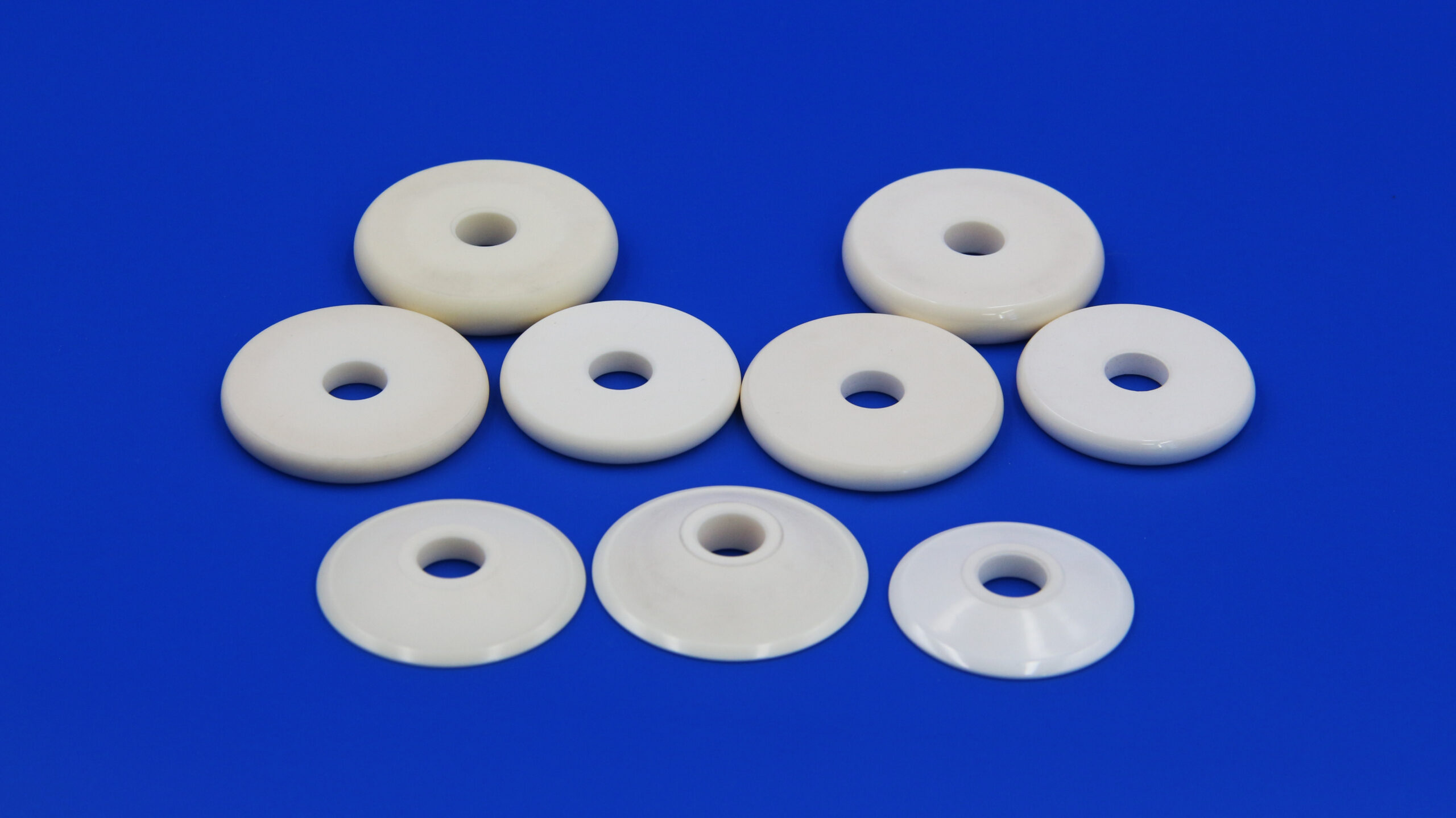

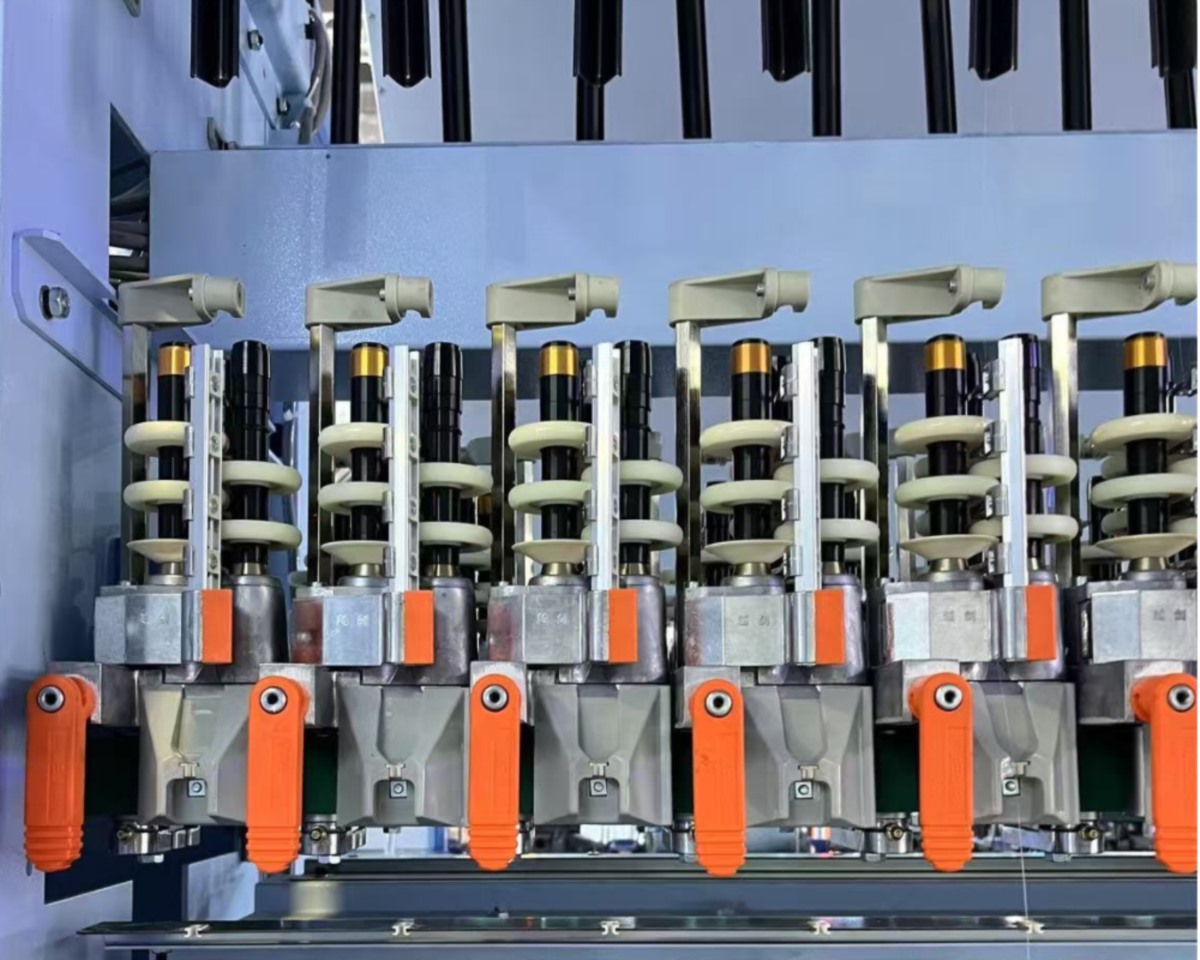

The DTY Barmag FK6 texturing machine ceramic components includes the ceramic friction disc, ceramic guiding disc, ceramic knife disc. The friction disc roughness is about Ra0.85μm, Ra1.0μm, Ra1.2μm, the knife disc and the guiding disc roughness is about Ra0.2-Ra0.3μm (the high speed machine is Ra0.2μm, low and medium speed machine both are Ra0.3μm.

Except the ceramic friction disc for DTY FK6 texturing machine ceramics, Innovacera also provides used friction disc repairing and other textile ceramic components such as ceramic eyelets, ceramic yarn guides, ceramic roller, ceramic oil applicator, ceramic pigtail, ceramic intermingling jet plates and ceramic traverse guide for the melt spinning process, ceramic navels for open-end spinning, ceramic cutter for cutting textile threads.

Ceramic Friction Disc Features:

Wear and corrosion resistance

Chemical resistance

Anti-static

Uniform dyeing

Easy maintenance

Good Yarn Properties-equivalent to PU.

Long service life

Wide spinning range

Excellent efficiency at high machine speeds

Ceramic Friction Disc Application:

1)According to spinning speed:

Low-speed machine ( speed: below 600 meters/minute):

868; 818; 800D; 800M; 800V texturing machine.

Medium-speed machine( speed: 600-650 meters/minute):

850; 900; 950; 980 texturing machine.

High-speed machine( speed: more than 650 meters/minute):

1000; 1200; 980; TMT, RPR texturing machine.

2)According to spinning varieties:

polyester elastic yarn, nylon elastic yarn, various composite yarns, core yarns, high elasticity twisted yarns, etc., including polyester highly lustrous, semi-dull, dull, colored yarns, cat-ionic yarns, and various network yarns.

Ceramic Guiding Discs General Size And Technical Data:

| Innovacera Ref NO. | D1(mm) | D2(mm) | H(mm) | R(mm) |

| G520129 | 52 | 12 | 9 | 5.5 |

| G496126 | 49.6 | 12 | 6 | 3.5 |

| G450126 | 45 | 12 | 6 | 3.5 |

Ceramic Friction Disc General Size And Technical Data:

| Innovacera Ref NO. | D1(mm) | D2(mm) | H(mm) | R(mm) |

| F445126 | 44.5 | 12 | 6 | 2.5 |

| F450126 | 45.0 | 12 | 6 | 3.7 or 3.5 |

| F450129 | 45.0 | 12 | 9 | 5.5 |

| F455126 | 45.5 | 12 | 6 | 3.7 |

| F455166 | 45.5 | 16 | 6 | 3.7 |

| F460166 | 46.0 | 16 | 6 | 3.5 |

| F472106 | 47.2 | 10 | 6 | 4.5 |

| F477129 | 47.7 | 12 | 9 | 4.5 |

| F490129 | 49.0 | 12 | 9 | 3.5 |

| F510126 | 51.0 | 12 | 6 | 3.3 |

| F512126 | 51.2 | 12 | 6 | 3.3 |

| F515129 | 51.5 | 12 | 9 | 3.3 |

| F520169 | 52.0 | 16 | 9 | 5.5 |

Ceramic Knife Disc General Size And Technical Data:

| Innovacera Ref NO. | D1(mm) | D2(mm) | H(mm) | R(mm) |

| K490129 | 49 | 12 | 9 | – |

| K470126 | 47 | 12 | 6 | – |

| K435126 | 43.5 | 12 | 6 | – |

Our workflow is start with your needs of textile machine types, spinning variety, DTY specifications and performance requirements and then according to our professional experience, we can improve your project by material selection, size selection, friction coefficient design and your brand design. We can work together to achieve your goals by samples testing, production parameter adjustment, mass production, quality control and after sales service.

Enquiry

Enquiry