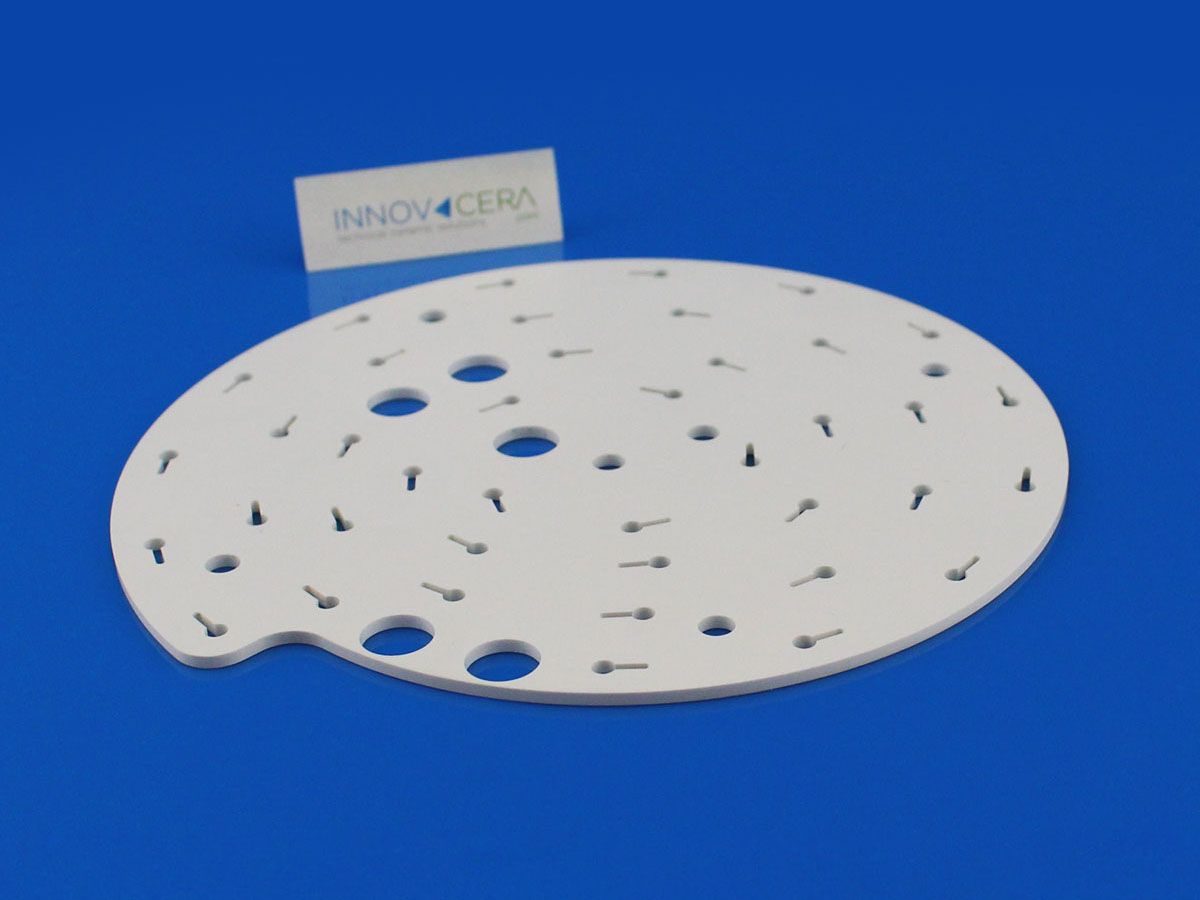

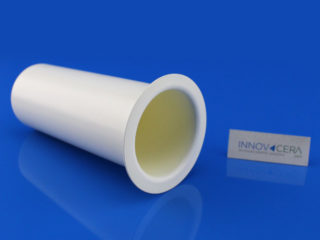

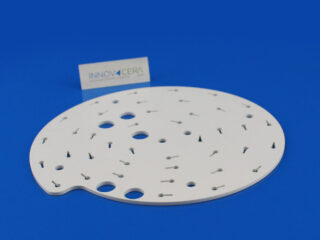

Innovacera PBN ceramic part includes the PBN Disc, PBN Sheet, PBN Filament Ring, PBN VGF Crucibles, PBN LEC Crucibles, PBN MBE Crucibles, PBN Conical Crucible, and Other PBN Machined Custom Parts.

PBN is a grade of hexagonal boron nitride. It is made by a chemical vapor deposition process to create its robust body, and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited. Due to the nature of the CVD process, the PBN products generally request the product; thick wall products are not more than 3mm. PBN is also the right choice for extremely high purity boron nitride. As the purity of gas material (BCl3 + NH3 –> BN +HCl) is a lot higher than regular boron nitride powder, purity for PBN is quite high, and 99.99% is the average grade. With its high purity, high mechanical strength, high performance with molten metal, and salts, PBN is becoming a widely used material in high vacuum processes. Without showing melting point and high thermal conductivity, pyrolytic content is ideal to be used as a vacuum furnace part. The CVD process gives this PBN an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing.

Molecular beam epitaxy (MBE) is a standard process for gallium GaAs crystal production, and PBN is the ideal material to make MBE crucibles.

Innovacera Performance Pyrolytic boron nitride properties are as below:

Good thermal conductivity

High insulation resistance

High dielectric strength over wide temperature ranges

Extremely pure

Non-wetting

Non-toxic

Non-reactive to most other compounds

Withstand high temperatures and rapid cooling

Retail: INNOVACERA® Pyrolytic Boron Nitride (PBN) Crucibles For MBE Chamber, OD25*ID7*52mm

Click to buy now: https://store.innovacera.com/product/pyrolytic-boron-nitride-crucibles/

Enquiry

Enquiry