Common Sintering Methods for Aluminum Nitride Ceramics

To prepare AlN ceramics with high thermal conductivity, two problems must be solved in the sintering process: the first one is to improve the densification of the material, and the second one is to try to avoid the lattice of oxygen atoms dissolved in the high-temperature sintering. Common sintering methods are as follows:

1. atmospheric pressure sintering

2. hot pressure sintering

3. high pressure sintering

4. atmosphere sintering

5. discharge ion sintering

6. microwave sintering

This Time, We Focus on Hot-pressing Aluminum Nitride:

In order to reduce the sintering temperature of aluminum nitride ceramics and promote the densification of ceramics, aluminum nitride ceramics can be prepared by using hot-pressure sintering, which is one of the main process methods for the preparation of high-thermal conductivity densified AlN ceramics. The so-called hot pressure sintering, i.e., sintering ceramics under a certain pressure, can make the heating sintering and pressurized molding at the same time. The AlN ceramic sintered body with a density of 3.26 g/cm3 and a thermal conductivity of 200 W/(m.K) was produced by sintering at a high pressure of 25 MPa and 1700°C for 4 h. The AlN lattice oxygen content was 0.49 wt%, which is more than 60% lower than that of the AlN sintered body obtained by sintering at 1800°C for 8 h (1.25 wt%), and the thermal conductivity was improved.

Xiamen Innovacera Advanced Materials CO., LTD

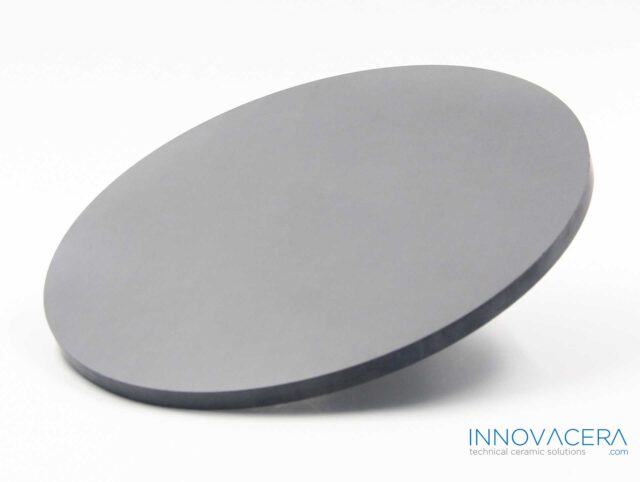

Has advanced production lines for aluminum nitride ceramic materials and high precision machining capabilities. We are currently able to produce Aluminum Nitride ceramic wafer in different sizes from 6-12 inches, as well as large Aluminum Nitride ceramic plates with a diameter of up to 320mm and a thickness of over 26mm. These large size ALN ceramic wafers can be used to produce high thermal conductivity aluminum nitride heating pads.

Table of Properties of Hot Pressed Aluminum Nitride:

| Hot Pressed Aluminium Nitride Material Properties – SU0023 | |||

| Properties | Units | Value | |

| Color | – | Black | |

| Bulk Density | g/cm3 | – | |

| Compressive Strength | MPa | 3416 | |

| Flexural Strength | MPa | 337 | |

| Modulus of Elasticity | GPa | 331 | |

| Fracture Toughness | MPa·m1/2 | 4.93 | |

| Coefficient Linear Thermal Expansion |

RT-500℃ | 10-6/k | 5.0732 |

| RT-800℃ | 5.3463 | ||

| Volume Resistivity | Ω.cm | 7.0×1012 | |

| Remark: The value is just for review, different using conditions will have a little difference. | |||

Enquiry

Enquiry