INNOVACERA widen its range of materials with Beryllium Oxide

Beryllium Oxide (BeO), which is commonly referred to as Beryllia, is endowed with a virtuously unique combination of thermal, electrical, optical, and mechanical properties which may be exploited for a diverse range of applications from thermal management systems for integrated electronics to high-temperature high-performance refractory components for nuclear reactors.

Applications of Beryllium Oxide Ceramics

- Medical

- Lasers

- Semiconductor handling equipment

- Energy

- Military and Aerospace

- Wireless Communications

Metallized Ceramic Joining types:

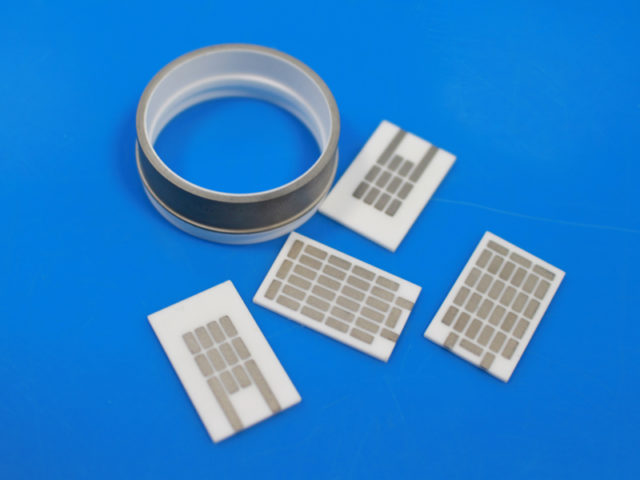

- BeO Ceramic + Mo/Mn Metallized + plating Ni

- BeO Ceramic + Mo/Mn Metallized + plating Ag

- BeO Ceramic + Mo/Mn Metallized + plating Au

- BeO Ceramic + printing Ag

Special types are available according to the customer’s drawings or samples.

Beryllium Oxide Metallization Ceramic Components for Thermal Management Solutions

Enquiry

Enquiry