Traditional white alumina ceramics have held a significant market position in electronic packaging applications due to their excellent electrical insulation, high-temperature resistance, and mechanical strength. However, with the rapid miniaturization and high-powerization of optoelectronic devices, users’ demands for the optical purity and signal accuracy of products have become increasingly strict. The high-reflectivity white ceramic surface can no longer meet the requirements of many high-precision packaging fields. For this purpose, black alumina ceramic materials were developed. These materials not only retain the original characteristics of the materials but also possess excellent light absorption properties and low reflectivity.

Black alumina ceramics are made from alumina materials by doping specific metal or non-metal ions. These dopants can absorb various light waves in the visible light spectrum, thereby achieving a stable black appearance. This material can meet the light-shielding requirements of some electronic products in high-reliability packaging. Moreover, compared with other ceramic materials, it has numerous advantages and enjoys extensive practical value in industrial applications.

The core advantages of black alumina in ceramic packaging:

(1) Excellent light-blocking and anti-reflective performance: Maintaining the purity of light signals

Traditional white alumina ceramics are semi-transparent, allowing light to pass through easily. This property can cause interference for light-sensitive devices (such as optical sensors and image sensors). In contrast, the surface light reflection rate of black alumina ceramic is lower, which can effectively reduce stray light and prevent light from reflecting onto the chip surface within the device cavity, thereby improving the purity of the laser output light and the signal-to-noise ratio of photoelectric detection.

This is precisely where its key value lies in laser module packaging, camera modules, and photo-sensitive sensors.

(2) Excellent heat dissipation performance: Rapid heat release

(3)Black alumina, due to the addition of carbon-based or metal oxide particles with higher thermal conductivity during the sintering process, has stronger infrared absorption and thermal radiation capabilities. This feature not only improves the overall thermal conductivity of the material but also enables faster heat dissipation and release in high-power packaging, significantly reducing the accumulation of thermal stress in devices, maintaining stable device temperatures, thereby extending service life and enhancing system reliability.

(4) High electromagnetic shielding efficiency: The “invisible protective layer” of the chip

By using special doping systems or microstructure design, black aluminum oxide can absorb and reflect electromagnetic waves while maintaining electrical insulation, achieving effective electromagnetic interference (EMI) shielding. It not only prevents internal signals from leaking out but also guards against external interference waves, ensuring the stability and reliability of the equipment’s operation.

Note: Not all black alumina materials possess significant EMI shielding capabilities. Functional packaging requires optimized designs, such as the addition of conductive phases or carbon doping.

(5) Inheritance of basic characteristics: A reliable foundation for packaging

Black alumina retains the fundamental advantages of white alumina ceramics, providing a solid foundation for microelectronic packaging design:

·High electrical insulation: Suitable for power devices and microelectronic substrates

·High mechanical strength and hardness: Ensuring the long-term stability of micro pads, substrates, bases, and casings

·Thermal expansion coefficient matched with the chip: Reducing cracks or peeling caused by temperature cycling

·Chemical stability: Capable of withstanding cleaning, reflow soldering, and various chemical environments

(6) Metalization processing capability: Multi-functional packaging capability

Black alumina ceramics can undergo various metallization processes, such as wire bonding, glass sealing, soldering, and other complex packaging techniques. By depositing metal layers such as Ni, Mo/Mn, or Ag on the ceramic surface, it can achieve a reliable connection with electronic chips or other packaging components, while ensuring airtightness and mechanical stability.

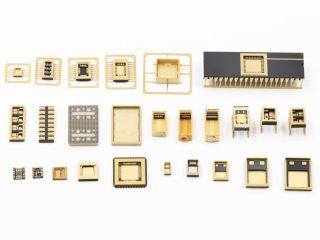

Application Examples:

Laser diode packaging and photodetector module: As a substrate or spacer, black oxidized aluminum ceramics can effectively absorb internal stray light, improve the purity of the laser output beam, while ensuring the high insulation and mechanical stability of the package, and enhancing the long-term reliability of the device.

Black support piece for camera module / Shading pad: Used in optical components such as micro cameras and projection modules, it serves as a shading pad and structural support material, effectively reducing light reflection and cross-light interference, preventing the image from experiencing glare and ghosting, thereby ensuring the clarity and color accuracy of the imaging.

Miniature sensor packaging shell, chip base: In MEMS sensors, optical sensors, or high-precision microelectronic modules, black alumina ceramics can be used as packaging shells or chip bases. Its material properties not only match the thermal expansion coefficient of the chip and possess reliable airtightness, but also can withstand thermal shock and mechanical stress, block external light interference, and ensure the stability of the sensor performance.

Vacuum packaging and MEMS device black substrate: In vacuum packaging or MEMS systems, the black alumina ceramic substrate not only provides a strong and high-temperature-resistant structural support, but also has the functions of optical shading and electromagnetic interference shielding, offering comprehensive protection for precision components.

Innovacera can offer customized services for black alumina ceramic packaging products. For more information on these products, please contact sales@innovacera.com.

Enquiry

Enquiry