Sealing refers to the physical or chemical connection of two or more materials. Joining technology is one of the key technologies in glass and ceramic manufacturing, which can improve the product’s sealing, thermal resistance, and stability, thereby improving its reliability and service life.

The connection methods between ceramics and metals include mechanical connection, adhesive connection, brazing connection, solid-phase diffusion connection, instant liquid phase connection, melting welding, self-propagating high-temperature synthesis connection, friction welding, microwave connection, and ultrasonic connection, etc.

According to the connection method, it can be divided into mechanical sealing and welding sealing. Mechanical sealing mainly realizes through fasteners, sealing rings, etc., while welding sealing realizes through melting connection.

According to the material type, it can be divided into glass sealing and ceramic-to-metal sealing. Glass sealing is mainly used for connecting glass and glass, glass and metal, etc., while ceramic sealing is mainly used for connecting ceramic and ceramic, ceramic and metal, etc.

According to the use environment, it can be divided into vacuum sealing, high-temperature sealing, and low-temperature sealing. Vacuum sealing is mainly used for manufacturing vacuum containers and sensors, high-temperature sealing is mainly used for manufacturing high-temperature furnaces and heaters, and low-temperature sealing is mainly used for manufacturing low-temperature containers and refrigeration equipment.

In this article, we will focus on the brazing process

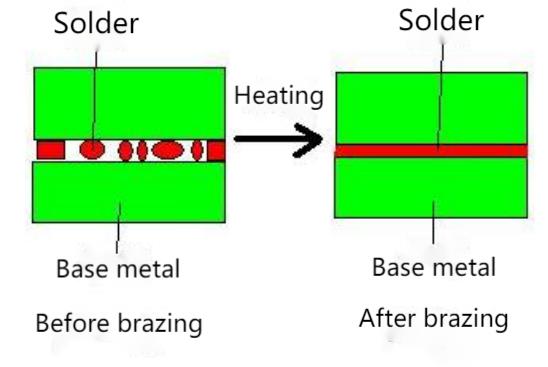

Brazing involves placing a metal (called the brazing filler or flux) with a lower melting point than the parent material (the material being brazed) between the parent materials; heating the assembly to a temperature below the melting point of the parent materials but above the melting point of the brazing filler, allowing the brazing filler to melt; allowing the molten brazing filler to wet, spread, and fill the voids between the parent materials; and allowing the parent materials to dissolve and diffuse into each other through the molten brazing filler. Upon cooling, a connection is formed between the parent materials with the brazing filler serving as an intermediate layer.

Advantages:

1)In the process of brazing, the weldment does not melt, and the size, structure and physicochemical properties of the weldment are stable

2)The welded joint has good air tightness and strength;

3) If the welded joint is bad, it can be re-welded;

4) Multiple welds can be welded at once.

Brazing also includes the following types

Metallized Ceramics

First, the ceramic surface is metallized, and then the conventional filler metal is brazed together, so it is also called two-step brazing. The purpose of ceramic surface and metallization is to solve the problem of poor wettability of the filler metal on the ceramic surface. The Mo-Mn method is commonly used in the electronics industry to premetallize the ceramic surface. The appropriate amount of Mn is added to the Mo powder to improve the combination of the metal coating and the ceramic. In addition, a series of metallization methods such as physical or chemical vapor deposition, thermal spraying, sintered metal powder method, ultrasonic method, chemical deposition, plasma injection and vacuum evaporation have been developed.

Active metal brazing

The wettability of the filler metal on the ceramic surface is improved by forming an active metal film on the ceramic surface, adding active elements to the filler metal and forming a reaction layer on the ceramic surface through chemical reaction. These active elements usually include Ti, Zr, Hf, V, Ta, Nb, Cr and so on.

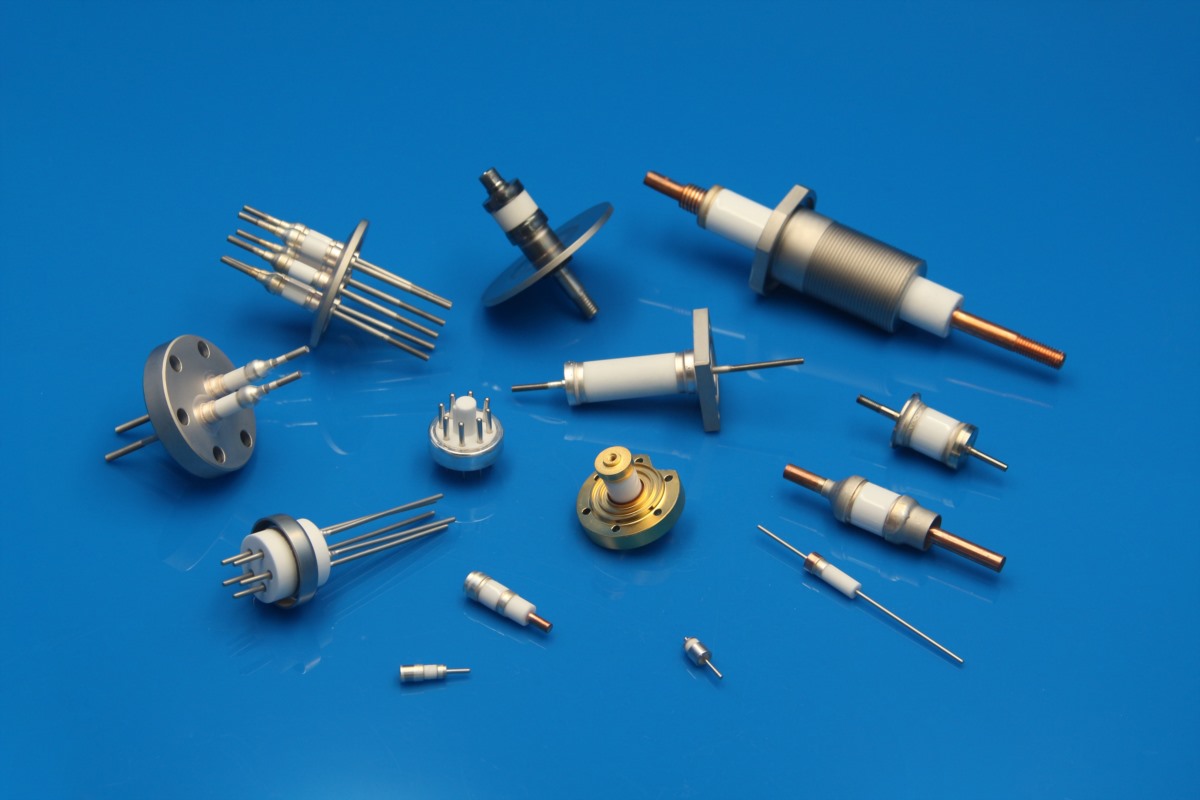

INNOVACERA is a professional enterprise integrating research and development, production and sales, providing various ceramic parts, ceramic to metal products. Currently involved in the application of vacuum equipment, lithography machine, vacuum coating machine, spectrometer, mass spectrometer, ion source, particle accelerator, electronic appliances, instrumentation, aerospace, new energy vehicles, intelligent robots, energy storage systems, chemical vacuum and so on.

Please feel free to contact us for any request. Provide one-stop service for drawing and sample.

Enquiry

Enquiry