The Use of Silicon Nitride Ceramic

Silicon nitride ceramic is composed of silicon and nitrogen atoms. Its volume density is around 3.26g/cm and its hardness is more than 1600MPa.

Here is the material properties :

![]()

With the material properties above, it possesses a range of characteristics that make it valuable in various applications:

1. Lightweight: Compared to steel materials silicon nitride ceramics are relatively lightweight about 60%. This characteristic is beneficial in applications where weight reduction is important.

2. High-Temperature Stability: Silicon nitride ceramics can endure high temperatures without losing their mechanical properties. They can retain strength and integrity even at temperatures exceeding 1000°C, with a max working temperature of 1650 °.

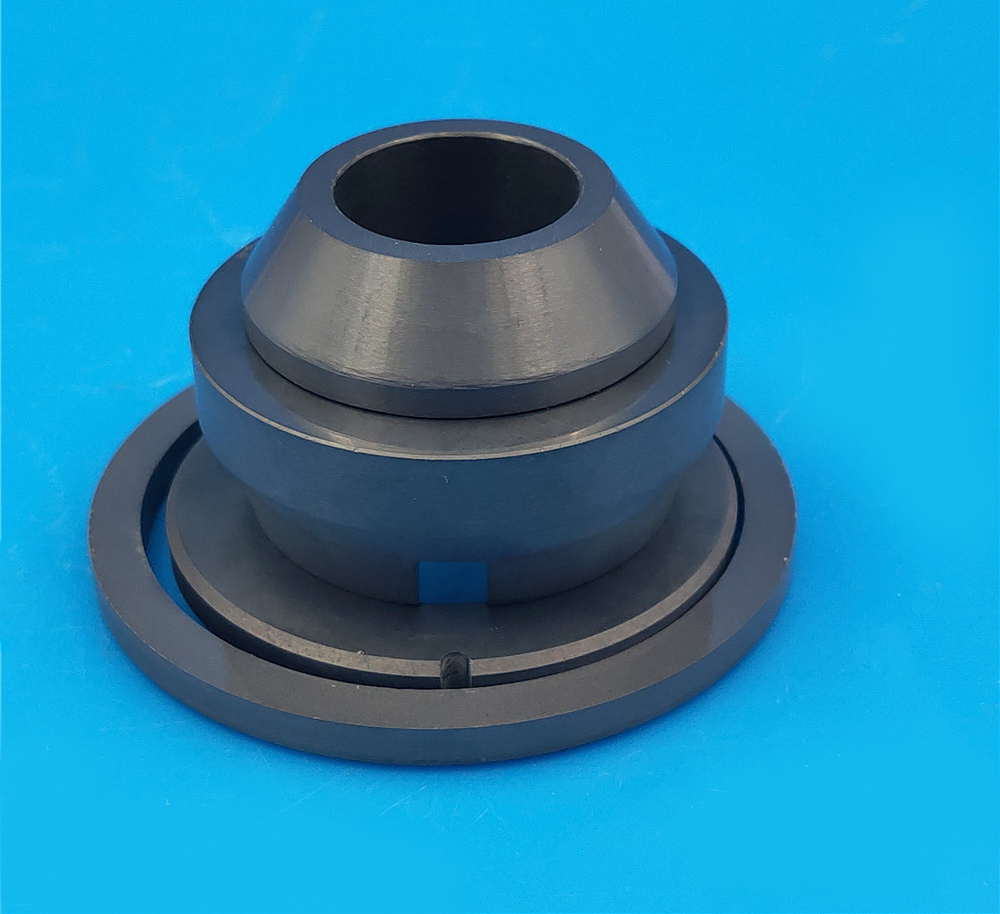

3. Mechanical Strength: Silicon Nitride Tube has excellent mechanical properties, including high hardness, strength, and toughness. It can endure heavy loads and resist fracture, suitable for structural components in demanding applications like valves.

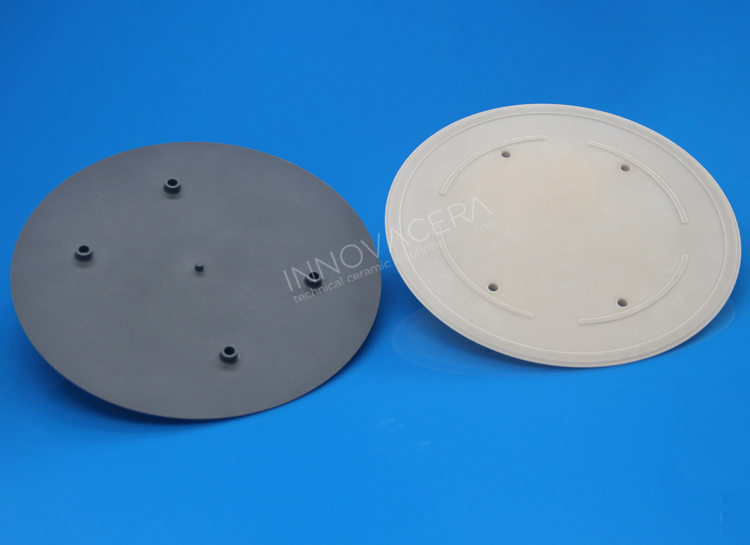

4. Electrical Insulation: Silicon nitride ceramics is an excellent electrical insulator, with high dielectric strength and low electrical conductivity.

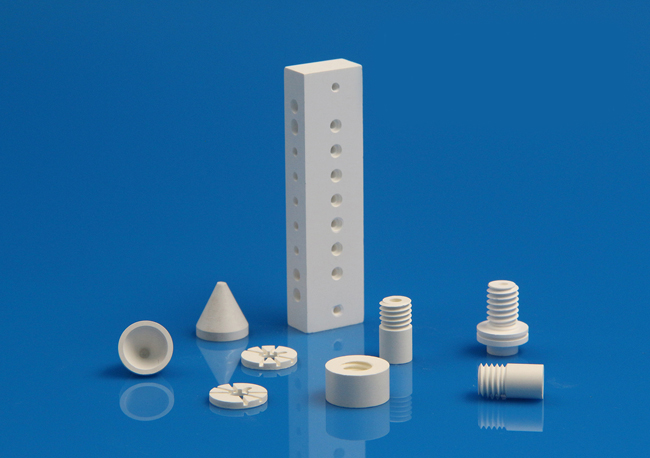

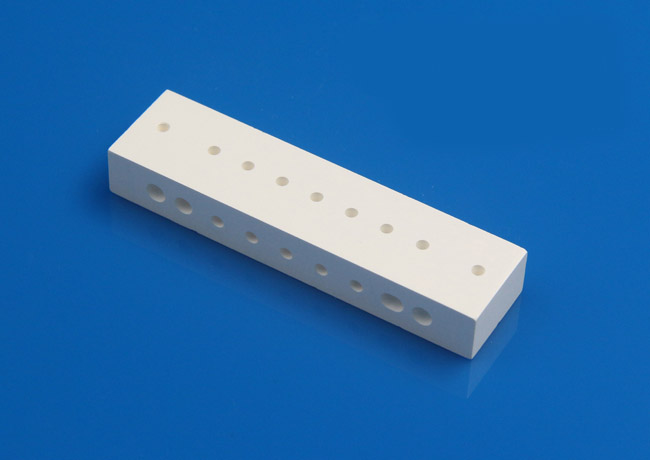

![]()

With characteristics of lightweight, high-temperature stability, mechanical strength, and electrical insulation on chemical inertness, it has many applications:

*Ball Bearings and Rolling Elements: Silicon nitride balls and rollers are used in bearings where high-speed rotation, high temperature, and corrosion resistance are required. Compared to traditional steel bearings, it has superior hardness and low friction.

*Gas Turbines and Aerospace Components: Silicon nitride components are used in gas turbines and aerospace due to their excellent thermal shock resistance, high-temperature strength, and lightweight properties.

*Electronics and Semiconductor Industry: Silicon nitride is used as an insulating material in electronic devices and semiconductor manufacturing. It is employed in components such as insulating layers and substrates due to its excellent electrical insulator, high-temperature stability, and chemical inertness.

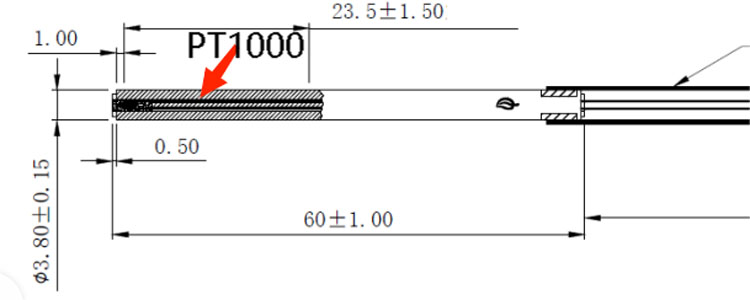

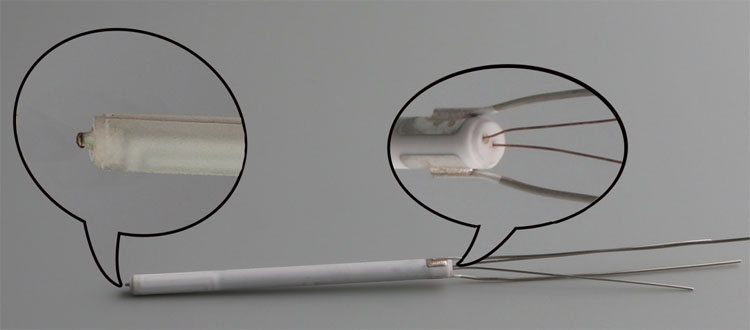

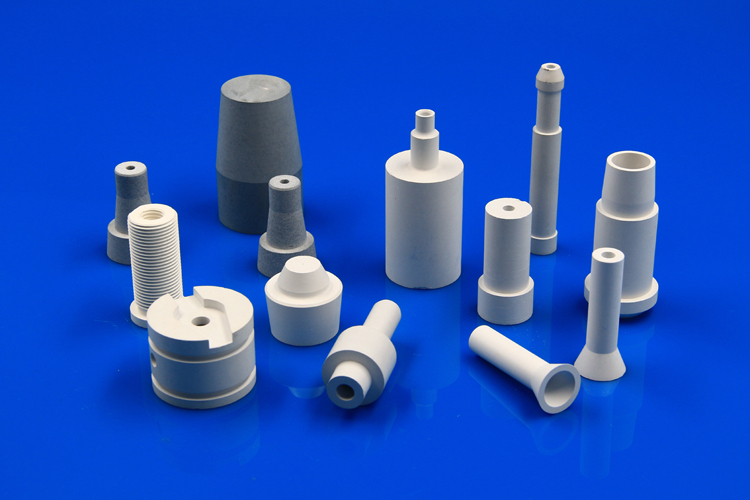

*High-Temperature Furnace Components: Silicon nitride components such as thermocouple protection tubes, radiant tubes, and heating elements are used in the construction of high-temperature furnaces, kilns, and heating elements due to their ability to withstand extreme temperatures and thermal cycling without degradation.

Silicon nitride ceramic has been used in the above industries.

Its exceptional properties high strength, toughness, thermal shock resistance, and corrosion resistance, make it a good choice for demanding applications. From the semiconductor industry to aerospace components, silicon nitride ceramics offer reliability and longevity, contributing to performance and efficiency. However, high processing costs and difficulty in machining limit its widespread adoption. Nonetheless, our engineering team keeps ongoing research and development aim to solve these hurdles, unlocking further potential for silicon nitride ceramic in diverse fields.

Enquiry

Enquiry