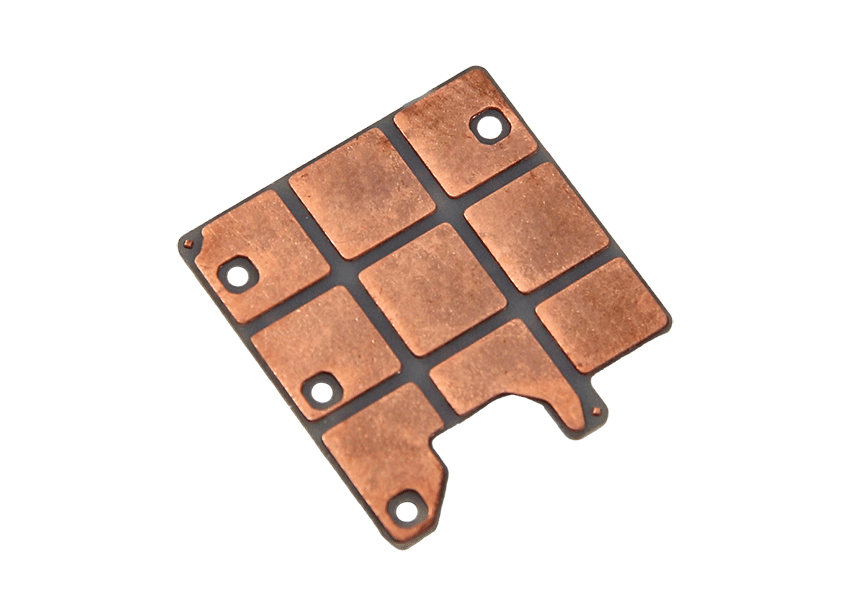

AMB (Active Metal Brazing) is a method of sealing ceramics and metals developed on the basis of DBC technology.

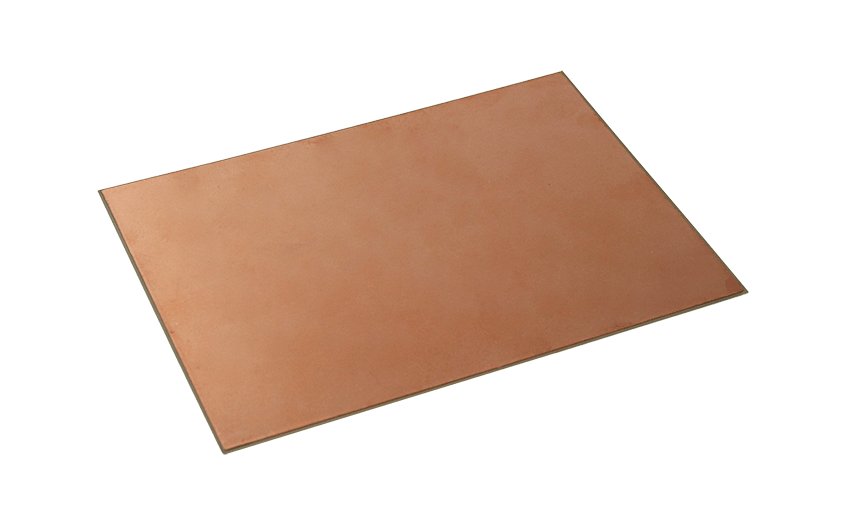

Compared with traditional DBC substrates, ceramic substrates prepared by AMB process not only have higher thermal conductivity and better copper layer bonding, but also have advantages such as lower thermal resistance and higher reliability. In addition, because its processing process can be completed in one heating, it is easy to operate, has a short time cycle, good sealing performance and a wide range of applications for ceramics, so this process has developed rapidly at home and abroad and has become a commonly used method in electronic devices.

AMB process description

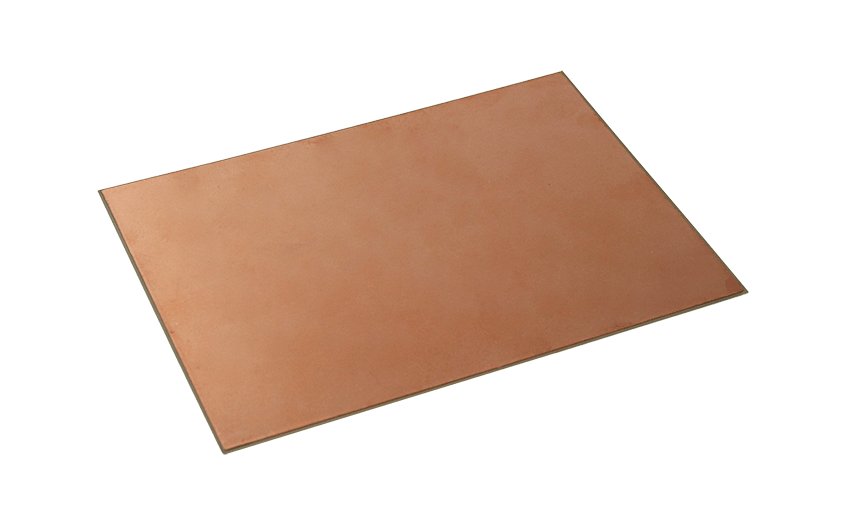

AMB is to add active elements to the brazing material, form a reaction layer on the ceramic surface through chemical reaction, improve the wettability of the brazing material on the ceramic surface, so that the ceramic and the metal can be directly brazed and sealed.

Usually, the active element content is between 2% and 8% with good activity. When the content of active elements is too high, the brittleness of the brazing material will increase, thereby reducing the strength of the sealing surface. When the content of active elements is too low, the wettability of the brazing material to the ceramic will decrease, making the sealing difficult to complete.

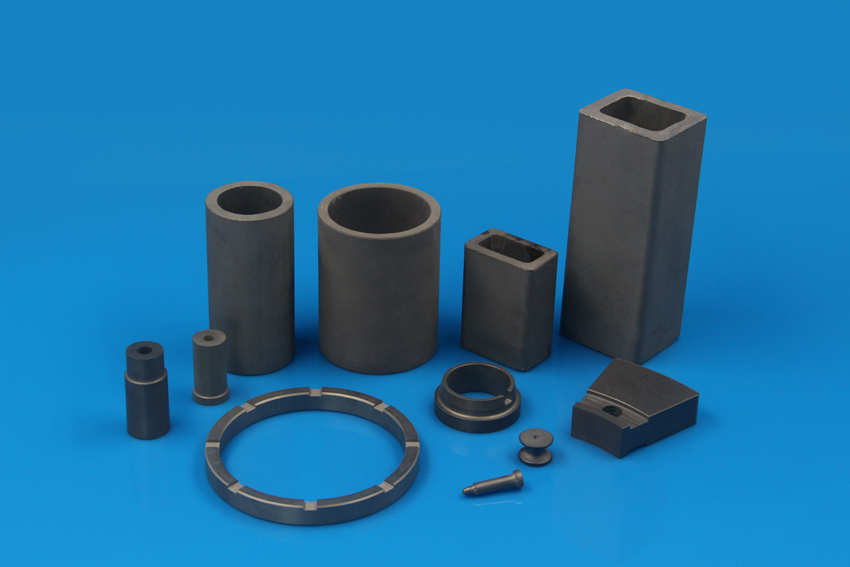

Three kinds of ceramic materials of AMB

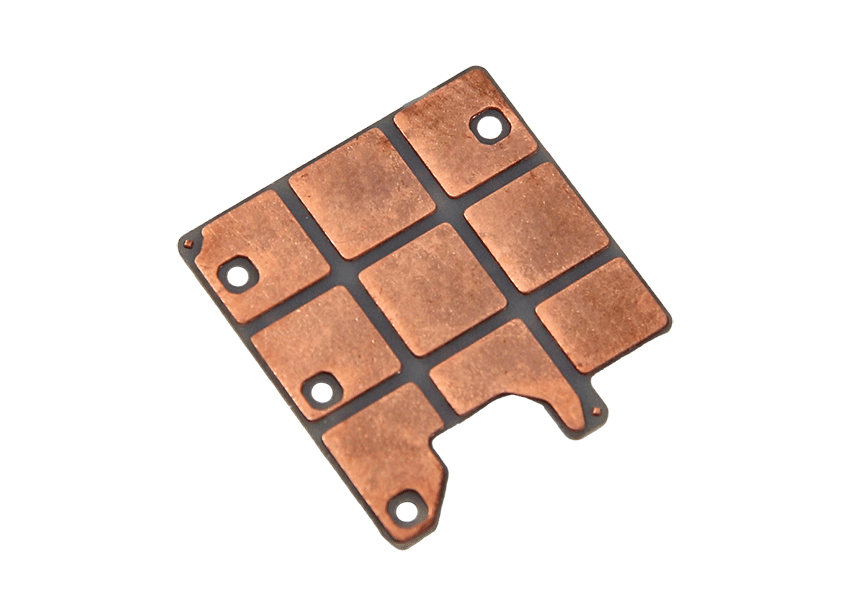

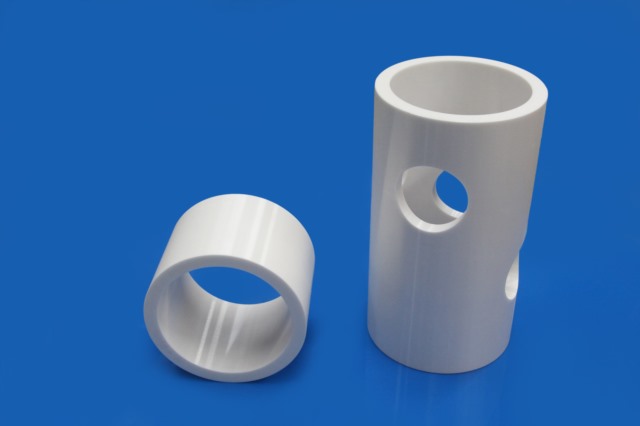

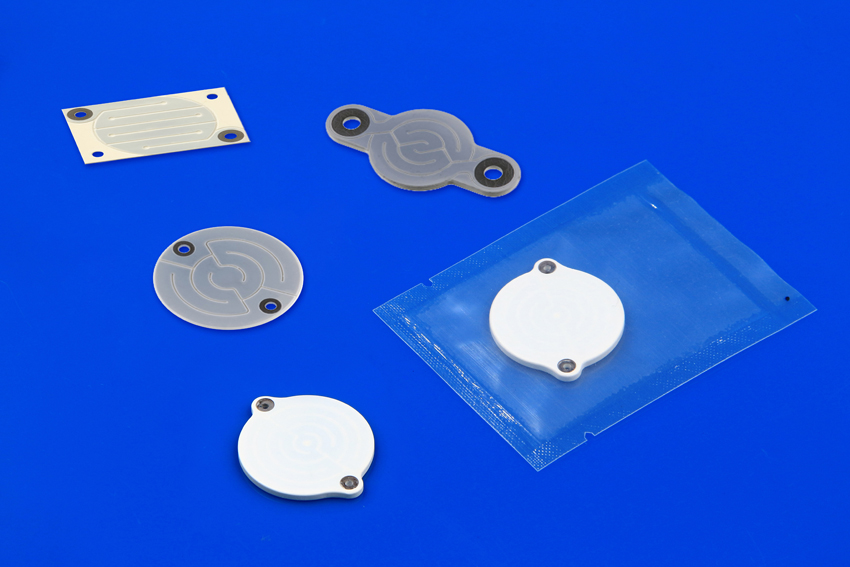

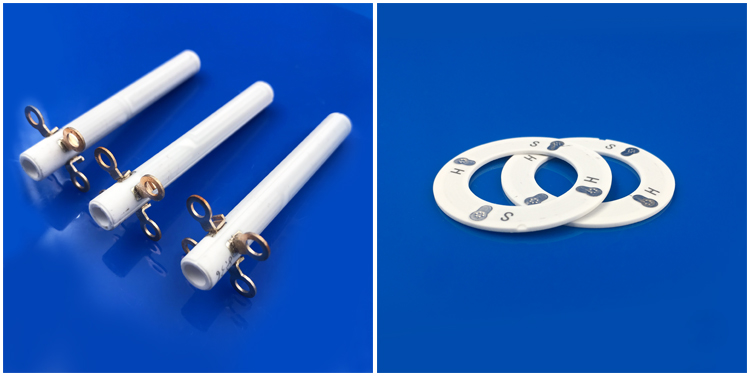

The ceramic lining produced by AMB process is mainly used in power semiconductor modules as the substrate of silicon-based and carbide-based power chips. At present, the mature AMB ceramic substrates are mainly: alumina, aluminum nitride and silicon nitride substrates.

At present, Al2O3 copper-clad ceramic substrates are mainly used in low-power heat dissipation devices such as LEDs, AlN and Si3N4 copper-clad ceramic substrates are mainly used in high-power IGBT modules such as high-speed rail and wind power generation.

1. Al2O3 ceramic substrate

Al2O3 ceramics are widely available and have the lowest cost. They are the most cost-effective AMB ceramic substrates with the most mature process. They have excellent characteristics such as high strength, high hardness, high temperature resistance, corrosion resistance, wear resistance and good insulation performance.

However, due to the low thermal conductivity and limited heat dissipation capacity of alumina ceramics, AMB alumina substrates are mostly used in fields with low power density and no strict requirements on reliability.

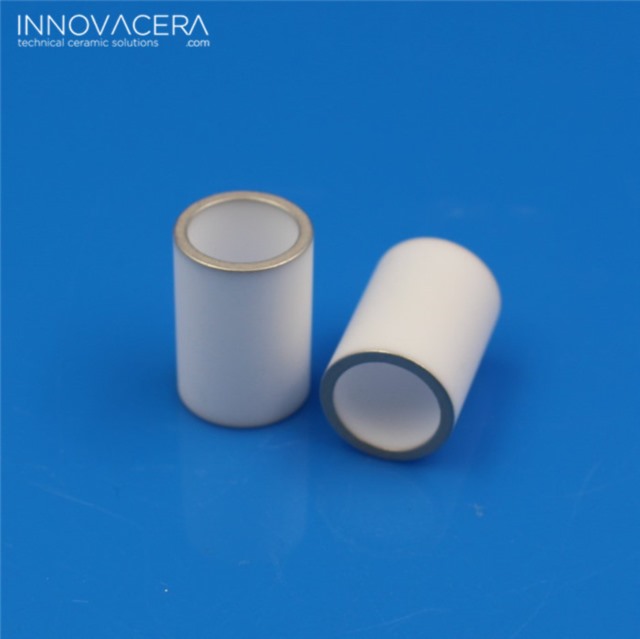

2. AlN ceramic substrate

AlN ceramic has better properties than traditional Al2O3 and BeO substrate materials due to its high thermal conductivity (theoretical thermal conductivity 319 W/(m·K)), low dielectric constant, thermal expansion coefficient matching that of single crystal silicon, and good electrical insulation performance, making it an ideal material for circuit substrate packaging in the microelectronics industry.

At present, aluminum nitride ceramic substrates (AMB-AlN) using the AMB process are mainly used in high-voltage and high-current power semiconductors such as high-speed rail, high-voltage converters, and DC power transmission. However, due to its relatively low mechanical strength, the high and low temperature cycle impact life of AMB-AlN copper-clad substrates is limited, which limits its application range.

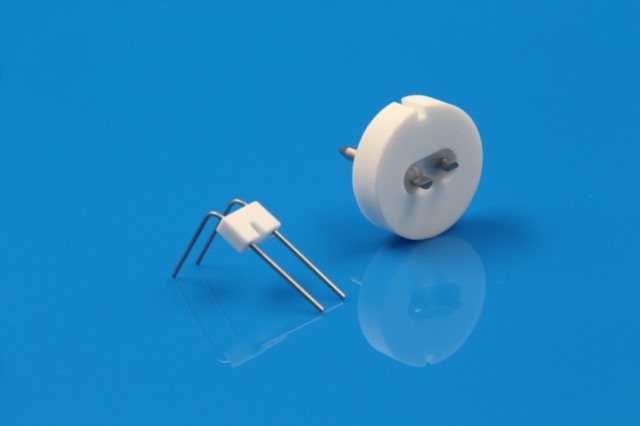

3. Si3N4 ceramic substrate

AMB-SiN ceramic substrates have high thermal conductivity (>90W/(m·K)), thick copper layer (up to 800μm), and high heat capacity and heat transfer. In particular, when a thicker copper layer is welded to a relatively thin AMB-SiN ceramic, it has a higher current carrying capacity and better heat transfer.

In addition, the thermal expansion coefficient of AMB-SiN ceramic substrate (2.4ppm/K) is close to that of SiC chip (4ppm/K), which has good thermal matching and is suitable for reliable packaging of bare chips.

At present, AMB-SiN ceramic substrate is the preferred substrate material for application scenarios such as new energy vehicles, photovoltaic inverters, wind turbines and high-voltage DC transmission devices that require high reliability, high heat dissipation and partial discharge.

According to statistics, the ceramic substrates used for power semiconductors above 600V are mainly DBC and AMB processes, among which AMB silicon nitride substrates are mainly used for electric vehicle (EV) and hybrid vehicle (HV) power semiconductors, and AMB aluminum nitride substrates are mainly used for high-voltage and high-current power semiconductors such as high-speed rail, high-voltage converters, and DC power transmission.

Conclusion

The market demand for AMB ceramic substrates has increased, among which the rapid growth of electric vehicles, the accelerated installation of SiC, and the rapid growth of new energy vehicles are the main driving factors.

If you have any question about the AMB substrate, welcome to contact us at sales@innovacera.com.

Enquiry

Enquiry