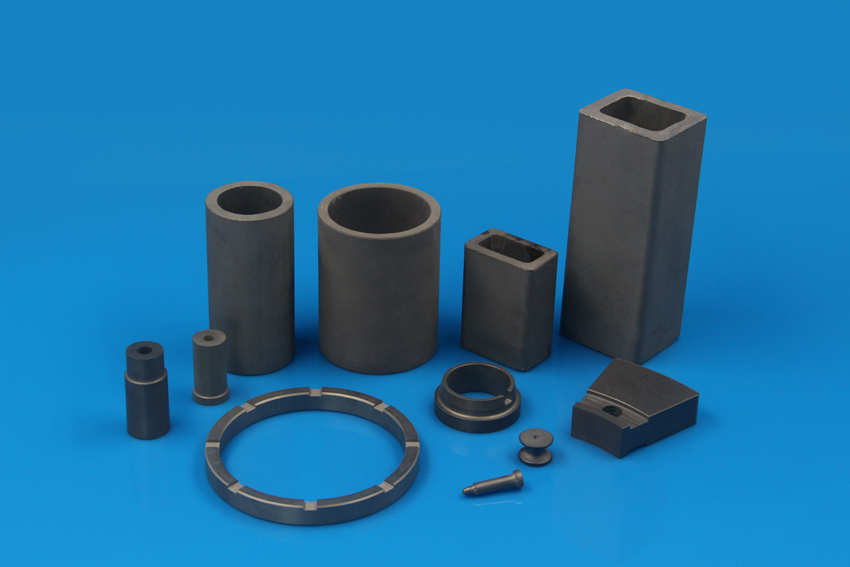

Silicon carbide ceramics is a kind of silicon carbide (SiC) as the main component of the ceramic material, with excellent mechanical properties at room temperature and high temperature mechanical properties, including high bending strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low friction coefficient. The high temperature strength of this material can be maintained to 1600 ° C, which is the best high temperature strength of known ceramic materials.

![]()

The following is a brief introduction to the properties and applications of silicon carbide ceramics

(1) Performance

Silicon carbide ceramics have the best oxidation resistance among carbides. However, between 1000 and 1140 ° C, the oxidation rate of SiC in the air is larger. It can be broken down by molten alkali.

Silicon carbide ceramics have good chemical stability, high mechanical strength and thermal shock resistance.

The volume resistivity of silicon carbide does not change much in the range of 1000~1500℃, and this characteristic can be used as a resistance heating element material. Silicon carbide heating resistance itself can also be called thermistor or semiconductor resistance. The resistivity of different types of silicon carbide thermistors varies with temperature.

(2) Application

Silicon carbide ceramics are widely used in various industrial fields, and its uses are as follows:

| Industrial | Working environment | Application | Principal advantage |

| oil industry | High temperature, high hydraulic pressure, grinding | Nozzles, bearings, seals, valves

|

wear-resisting |

| chemical industry | strong acid, strong alkali | Seals, bearings, pump parts, heat exchangers

|

Wear resistance, corrosion resistance, air tightness |

| high temperature oxidation | Gasification pipeline, thermocouple sleeve | High temperature corrosion resistance | |

| Cars & Planes | Engine combustion | Burner components, turbocharger rotor | Low friction, high strength, low inertial load |

| Cars & Engines | engine oil | Valve series element | Low friction, wear resistance |

| Machinery, Mining | grinding | Borax nozzle, lining, pump parts | wear-resisting |

| paper industry | pulp, waste liquid | Seal, casing, bearing, forming plate | Wear resistance, corrosion resistance, low friction |

| heat treatment smelting steel | high-temperature gas | Thermocouple bushing, radiation tube, heat exchanger, combustion element | Wear resistance, corrosion resistance, air tightness |

Innovacera has been focusing on providing customers with ceramic material solutions for many years. Including but not limited to silicon carbide ceramic parts customization, if you have any needs, please feel free to contact us.

Enquiry

Enquiry