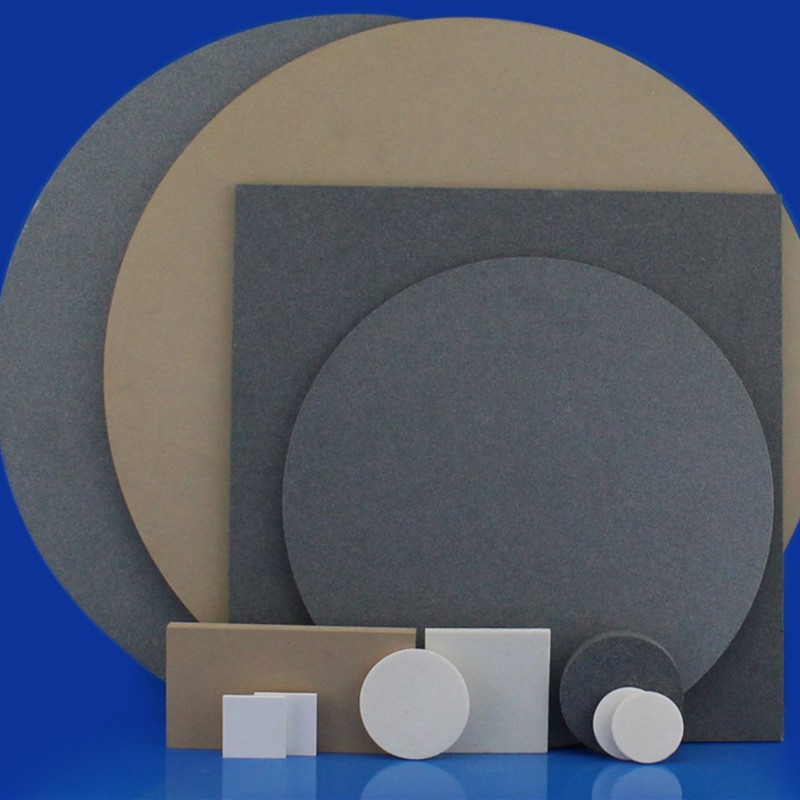

Innovacera have two materials as Porous ceramics one is Aluminum Oxide and the other one is Silicon Carbide. For Aluminum oxide, the common pore size we make is 1um, 15um, 30um, 40um, 50um and 100um. Silicon carbide general pore size is 15um, 30um and 50um, both material porosity is 40%-50% . For other hole size and porosity, it can be customized as well with large quantity.

Between two, Aluminum oxide is more common used than silicon carbide as it is cost effective. But if you need to use under the max working temperature 800 degree-100degree, silicon carbide is only the one that available because Aluminum oxide with max 800 degree.

Here is the material data sheet for both:

Alumina Porous ceramic properties:

| Material composition: | Al2O3>=80%, SiO2 16%-18% |

| Density: | 2.3g/cm2-2.5g/m3 |

| Hardness: | >=50HRA |

| Flexural Strength: | >= 40MPa |

| Compressive Strength: | >=600 |

| Porosity: | 40% |

| Pore Size: | 1-2um, 5um, 15um, 30um, 40um, 50um, 100um and customized |

| Max Working temperature: | 800 degree |

| Operating Pressure: | <=10MPa |

| Acid Resistance: | <=10mg/cm2 |

| Alkali Resistance: | <=20mg/cm2 |

Silicon Carbide Porous ceramic properties:

| Material Composition: | SiC>=88%, SiO2 12% |

| Density: | 2g/cm2-2.2g/m3 |

| Hardness: | >=40HRA |

| Flexural Strength: | >= 30MPa |

| Compressive Strength: | >=500 |

| Porosity: | 45% |

| Pore Size: | 15um, 30um, , 50um and customized |

| Max working temperature: | 1000 degree |

| Operating Pressure: | <=10MPa |

| Acid Resistance: | <=15mg/cm2 |

| Alkali Resistance: | <=25mg/cm2 |

With properties like excellent chemical resistance, good wearing and erosion resistance in acid and alkali conditions, withstanding high temperature and uniform pore structure, porous ceramics are excellent material as filters in various industries. Here are part of common use:

1.Water Filtration: Porous ceramics can filter sediments, bacteria and other pollutants in water.

2. Air Filtration: Porous ceramics can remove contaminants and particulate matter from the air.

3. Oil and Chemical Filtration: Porous ceramics can separate impurities from oils and solvents, improving the quality of products.

4. Catalytic Filters: Porous ceramic can filter unwanted byproducts to facilitate chemical processes in automotive and industrial applications.

Besides the applications list above, it can also use in capillary electrophoresis, high temperature chemical support for gas absorption, high efficiency flow through catalytic supports, gas burners and chromatography.

Porous ceramics are effective as filters due to several key properties:

1.Pore Structure: in porous ceramic, it has the interconnected pores which can create a network allowing fluids to pass through while trapping particles and contaminants.

2.Chemical Stability: with good wearing and erosion resistance in acid and alkali conditions, it is suitable for filtering various fluids.

3.High Temperature Resistance: porous ceramics can withstand high temperatures max 1000 degrees.

Those properties make porous ceramics an ideal material applied as filters. Any more question about porous ceramic, just feel free to contact us at +86 592 558 9730 or sales@innovacera.com for more information.

Enquiry

Enquiry