- Characteristics of porous ceramic vacuum chuck

1). Ceramic Material: SiC, Al2O3; Base material: stainless steel/aluminum alloy, ceramic, marble

2). Porous Ceramic Porosity: 40%

3). Porous Ceramic Pore Size: 1-100μm

4). Size customization; flatness≤3μm;

5) The unique air circuit design and packaging process of aviation aluminum alloy base can realize selective vacuum area adsorption.

- Application field of porous ceramic vacuum chuck

1). It can absorb OLED, LCD, wafers, and other smooth and flat objects.

Please note: the contact area between the adsorbed substance and the ceramic should not be less than 10*10mm (the larger the adsorption area, the stronger the adsorption force).

When absorbing objects, it is not necessary to cover the unused area.

2). It can be used in both directions. Adsorption by vacuum and suspension of objects by positive pressure

Porous Ceramic Steel Disc

- How to use the porous ceramic vacuum chuck

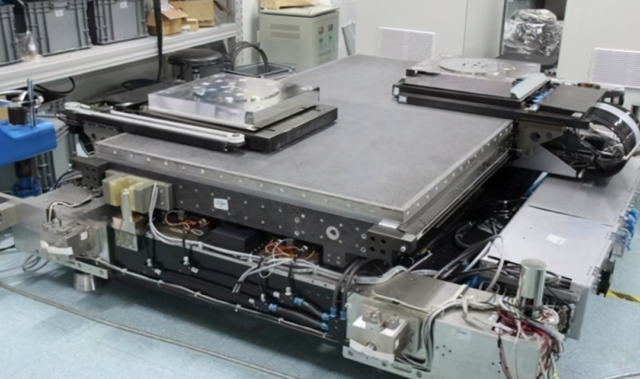

As shown in the figure, the internal structure of the vacuum chuck is divided into three areas: A, B, and C. When each area is vacuumed separately, the area covered by the ceramic can form a strong negative pressure.

Connect the three area air pipes in parallel to a vacuum generator, and install a solenoid valve as required.

Connect the air source (above 0.6Mpa), and open the air circuit in the corresponding area according to the size of the object.

POROUS CERAMIC VACUUM CHUCK Equipment

- Precautions in the use of porous ceramic vacuum chuck

1). Do not blow air under positive pressure. (If there is a need for air suspension, it can be customized)

2). Handle with care, do not scratch or hit the ceramic surface with hard objects, to prevent deformation from affecting accuracy and ceramic cracking.

3). Do not heat, the thermal shrinkage of the aluminum alloy /stainless steel base may cause the ceramic extrusion to crack.

4). It should not be contaminated with oil, glue, paint, and other pollutants, and should be used in a dust-free and oil-free environment as much as possible to prevent micropore blockage.

5). If there is dust and dirt on the surface, it can be pasted and removed with non-residual adhesive tape multiple times, or washed with a high-pressure water gun.

Enquiry

Enquiry