In recent years, the landscape of gas ignition technology has seen a transformative shift, particularly in China and the global market. While high-frequency ignition systems have long been the standard in Chinese households and industries, a growing trend towards hot surface ignition systems is reshaping the sector abroad. This innovative approach to ignition brings a multitude of benefits, offering a safer, more efficient, and reliable alternative to traditional methods.

The Drawbacks of High-Frequency Ignition

High-frequency ignition, though widely used, has several notable drawbacks that have become increasingly apparent. These include:

1.Noise Pollution: The high-pitched sound generated during ignition can be disruptive, particularly in residential settings.

2.Unsafe Deflagration: High-frequency ignition can lead to deflagration, where gas combusts explosively, posing safety risks.

3.Poor Ignition Reliability: The system’s dependency on precise conditions can result in inconsistent ignition performance.

4.Electromagnetic Interference: High-frequency signals can interfere with nearby automatic control equipment, leading to malfunctions.

These issues have spurred the demand for more advanced ignition solutions, and the international market has responded by adopting hot surface ignition technology.

The Emergence of Hot Surface Ignition

Hot surface ignition technology is rapidly gaining traction for its ability to address the shortcomings of high-frequency ignition. This method utilizes a heated element to ignite gas, thereby eliminating many of the risks associated with traditional ignition systems. Hot surface ignition offers:

Silent Operation: By reducing noise pollution, it enhances user comfort, especially in household environments.

Enhanced Safety: The controlled ignition process significantly reduces the risk of deflagration.

Increased Reliability: Hot surface ignition provides consistent performance across a variety of conditions.

No Electromagnetic Interference: Its operation does not affect other electronic devices, making it ideal for modern homes and industries.

The Role of SiC and Si3N4 Ceramics

Silicon Carbide (SiC) ceramic hot surface igniters have been a staple in the U.S. and EU markets for over 25 years. These igniters are commonly used in commercial and household gas devices, such as air conditioners and heaters. However, SiC igniters are not without their limitations:

Decentralization of Hot Area: The uneven distribution of heat can lead to inefficiencies.

Fragility: SiC igniters are prone to breakage, reducing their lifespan and reliability.

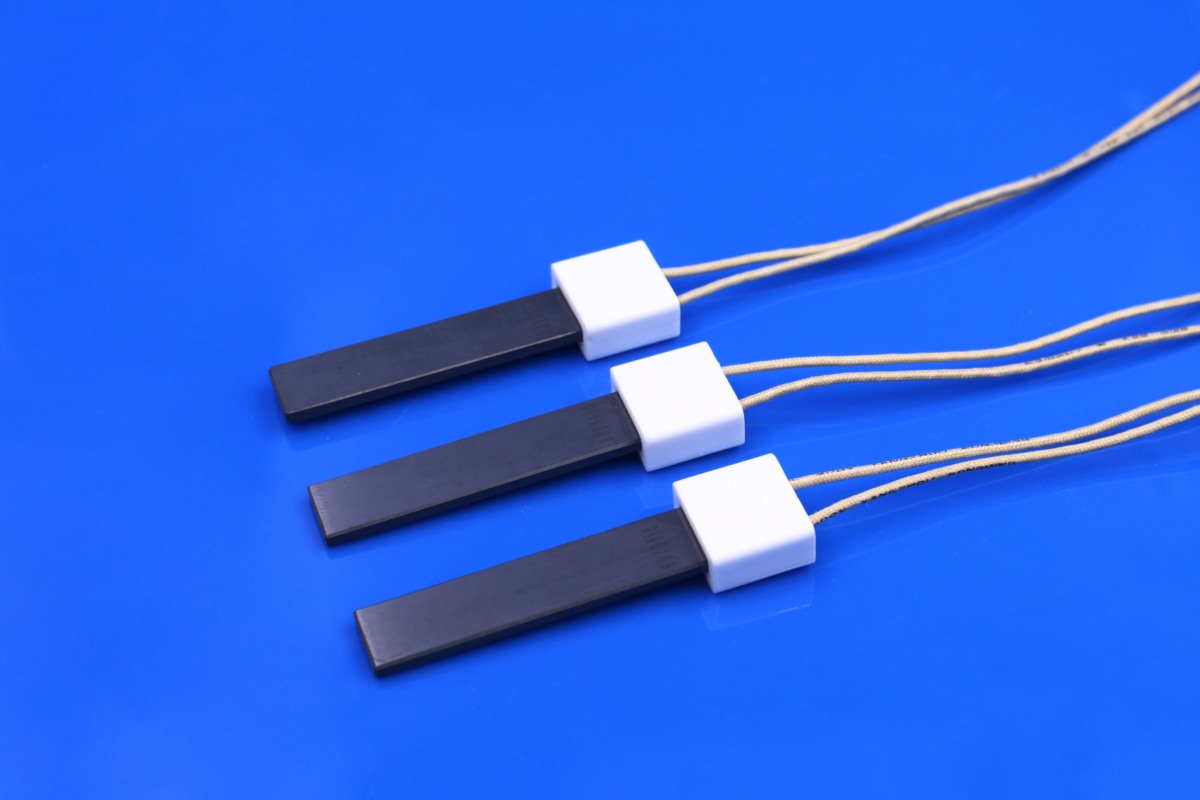

Enter Innovacera’s Si3N4 Igniters, which offer a groundbreaking solution. Innovacera’s silicon nitride igniters provide several advantages over traditional SiC igniters, revolutionizing the field of gas ignition.

Innovacera’s Si3N4 Igniters: A New Era in Ignition Technology

Innovacera has developed Si3N4 igniters that overcome the limitations of both high-frequency and SiC igniters. The features of these advanced igniters include:

100% Reliable Ignition: Innovacera’s igniters deliver consistent ignition performance, ensuring reliable operation in all conditions.

No Interference: The design eliminates any electromagnetic interference, making them compatible with modern electronic systems.

No Gas Leakage: The precision engineering of the igniters prevents gas leakage, enhancing safety.

High Mechanical Strength: These igniters are built to withstand mechanical stress, reducing the risk of damage.

Humidity and Thermal Shock Resistance: The igniters are designed to function effectively in humid environments and withstand sudden temperature changes.

No Special Controller Required: They are user-friendly and easy to integrate into existing systems.

Complete Replacement of SiC: Innovacera’s Si3N4 igniters match the installation modes and thermal electrical characteristics of SiC igniters, allowing for seamless upgrades.

Diverse Applications Across Industries

The versatility of Innovacera’s Si3N4 igniters opens the door to a wide range of applications, both commercial and residential. They are suitable for use in:

Gas Air Conditioners: Ensuring efficient and reliable ignition for optimal cooling performance.

Gas Air Heaters: Providing consistent warmth in residential and industrial settings.

Dryers: Enhancing the safety and efficiency of gas-powered drying appliances.

Cooking Appliances: From ranges to cooktops, these igniters ensure precise and reliable ignition for culinary applications.

Pool and Water Heaters: Offering dependable ignition for heating solutions in various environments.

Pyrotechnic Effects: Enabling safe ignition for fireworks and other pyrotechnic displays.

Mosquito Traps: Powering traps with reliable ignition for effective pest control.

As the demand for safer, more efficient ignition systems continues to grow, hot surface ignition technology stands at the forefront of innovation. Innovacera’s Si3N4 igniters represent a significant advancement in the field, providing a reliable, versatile, and user-friendly solution to meet the evolving needs of modern households and industries. With their wide range of applications and superior performance, these igniters are poised to become the new standard in gas ignition technology, paving the way for a more secure and efficient future. For more information please contact with us.

Enquiry

Enquiry