In 2025, the industrial manufacturing sector is facing an unprecedented challenge in terms of raw materials.

Due to the combined effects of environmental protection production restrictions, tightened mining quotas (with tungsten ore quotas expected to decrease by approximately 6.45% in 2025 compared to the previous year), and the growth in downstream demand from sectors such as photovoltaics and military industry, the price of tungsten concentrate has risen by nearly 80% this year, reaching a new high in the past decade. Meanwhile, the export restrictions on tungsten-related products have become stricter, putting pressure on enterprises that rely on tungsten steel (hard alloy) for manufacturing tools, wear-resistant parts, and molds, as they are confronted with both cost and supply issues.

Against the backdrop of continuous price hikes of tungsten steel and increasing supply uncertainties, finding mature and reliable alternative materials for tungsten steel has become an unavoidable topic for manufacturing enterprises.

As a materials and components supplier with over a decade of experience in the advanced ceramics field, Innovacera believes that this is not merely a simple material substitution, but rather a technological upgrade from metal materials to high-performance inorganic non-metallic materials.

1. Why are advanced ceramics becoming an important alternative to tungsten steel?

For a long time, tungsten steel has been widely used in high-maintenance and high-load working conditions due to its high microhardness and certain fracture toughness. However, under higher rotational speeds, higher temperatures, and more stringent chemical conditions, its limitations gradually became apparent. Advanced ceramics such as silicon nitride (Si3N4), silicon carbide (SiC), and high-strength oxide ceramics are replacing tungsten steel in various application scenarios.

(1)A Game-Changing Leap in Hardness and Service Life

Tungsten steel has long held a dominant position in the mainstream of wear-resistant materials due to its high microhardness (HV) and certain fracture toughness. In scenarios with high wear, such as the plunger of the slurry pump and the sandblasting nozzle, the service life of advanced ceramics is typically 3 to 10 times that of tungsten steel.

Application Implications: Even though the unit price of ceramics is slightly higher, from the perspective of total cost of ownership (TCO), if the number of downtime maintenance sessions is reduced by 80%, the overall cost not only offsets the price increase but also decreases by more than 30%.

(2) Overcoming the material bottleneck caused by tungsten steel’s high-temperature failure

The high-temperature performance of tungsten steel (WC-Co) is limited by its cobalt binder phase. It tends to soften and fail when the temperature exceeds approximately 800℃. In contrast, ceramic materials do not rely on metal bonding phases and exhibit better stability under high-temperature conditions. However, the temperature resistance capabilities of different systems vary. Take aluminum nitride ceramics as an example. They are more suitable for thermal conduction and electronic packaging applications. The long-term operating temperature in an oxidizing atmosphere such as air should generally be controlled within 800–1000℃; beyond this range, surface oxidation will accelerate the performance degradation. There is a risk of oxidation failure at approximately 1200℃, and this can be mitigated by coating or atmosphere protection. For applications involving higher temperatures, silicon nitride and silicon carbide offer greater advantages.

Scene advantages: In the face of demanding conditions such as high-speed dry cutting and semiconductor high-temperature processing, advanced ceramics have become one of the few materials that can operate stably over the long term, and have continuously replaced tungsten steel solutions in practical applications.

(3) The reduction in energy consumption resulting from lightweighting

The density of tungsten steel is approximately 15.7 g/cm³, which means it has a relatively high mass. Taking silicon nitride ceramic as an example, its density is about 3.2 g/cm³, and its weight is only about 1/5 of that of tungsten steel.

Technical value: In high-speed rotation or high-frequency start-up and shutdown conditions, such as those encountered in components like bearing balls, turbine rotors, and the end actuators of mechanical arms, ceramic materials can significantly reduce centrifugal force and rotational inertia, thereby enhancing the system’s response speed and improving overall energy efficiency.

2. Innovacera: Redefining the “Made in China” Ceramic Power

In the wave of the material revolution, Xiamen Innovacera Advanced Materials Co., Ltd. is not merely a supplier; it is also your technical partner.

We were established in 2012 and have three production bases covering an area of over 5,000 square meters. These bases are equipped with isostatic pressing, extrusion molding, and precision processing equipment. Unlike traditional ceramic workshops, we have obtained ISO 9001:2015 and IATF 16949 certifications, and are dedicated to converting materials such as alumina, zirconia, boron nitride, and silicon nitride into precise industrial components.

Our core alternative solutions (off-the-shelf/customized):

(1) Fluid control and metering pump systems are widely used in lithium battery charging and pharmaceutical filling industries. Our ceramic plungers and pump valve assemblies, with their excellent wear resistance and good chemical stability, effectively prevent metal ion contamination. In relevant working conditions, they can replace stainless steel and tungsten steel components, significantly reducing the risks of pump jamming and corrosion.

Explore our products: https://www.innovacera.com/products

(2) In high cleanliness processes such as chip manufacturing, our high-purity alumina arms, vacuum suction cups, and PBN (pyrolytic boron nitride) crucibles can effectively prevent the risk of metal ion contamination, replacing traditional tungsten steel components and meeting the demanding cleanliness requirements.

Online purchase: https://innovasupplies.com/catalog

(3) In the high-speed drawing and wire guiding process, the surface finish of our alumina ceramic guide wheels is extremely smooth. Compared to tungsten steel, they are more wear-resistant and can effectively reduce wire scratches. Experimental results show that the breakage rate can be reduced by approximately 80%.

(4) Under high-temperature welding and heat treatment conditions, our silicon nitride positioning pins have high hardness, are resistant to slag adhesion, and possess excellent insulation and heat resistance properties. They are an ideal alternative to traditional metal positioning pins in automotive welding fixtures, especially suitable for situations where insulation and hardness need to be balanced.

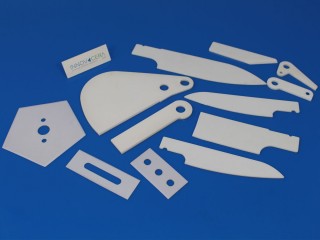

![]()

3. The strategic choice of maintaining high tungsten prices

The market signals for 2025 are very clear: fluctuations in the prices of resource-dependent materials (such as tungsten steel) will become the norm, while the cost-effectiveness of technology-driven materials (such as advanced ceramics) will continue to improve.

Don’t wait until the tungsten steel inventory runs out or the cost eats into the profit before taking action – now is the best time to upgrade the wear-resistant parts and structural components to advanced ceramics.

What kind of support can Innovacera provide for you?

– Material consultation: Unsure whether to choose zirconia or silicon nitride? Our engineers offer you free selection services.

– Rapid prototyping: Whether it’s a single-piece trial run or mass production, we can respond quickly.

– Global Direct Delivery: Through the online store Innova Supplies, you can

conveniently obtain standard industrial ceramic parts just like online shopping.

Enquiry

Enquiry