Pyrolytic boron nitride (PBN) belongs to the hexagonal crystal system, and its purity can reach 99.999%. It is acid and alkali resistant, anti-oxidation, has good thermal conductivity, is dense, and can be processed. Due to the CVD process, pyrolytic boron nitride has a near-perfect layered structure, resulting in anisotropic thermal conductivity, making it an ideal material for making crystal growth crucibles.

It is made of chemical vapor deposition (CVD) of ammonia and boron halides under high temperature and high vacuum conditions. It can not only prepare PBN sheets, but also directly prepare PBN final products such as crucibles, boats, and coatings.

Pyrolytic boron nitride is different from ordinary hot-pressed boron nitride (HBN). It does not need to go through the traditional hot-pressing sintering process and does not add any sintering agent.

Therefore,the obtained product has the following significant characteristics:

1. Non-toxic and tasteless;

2. High purity, reaching more than 99.999%;

3. It does not react with acids, alkalis, salts and organic reagents at room temperature, and is slightly corroded in molten salts and alkali solutions, but it can resist corrosion by various acids at high temperatures;

4. Does not react with most molten metals, semiconductors and their compounds;

5. Good antioxidant performance below 1000℃;

6. Thermal shock resistance is good, no cracks were found when put into water at 2000℃;

7. High operating temperature, no sublimation point, and directly decomposes into B and N above 3000°C;

8. High resistance and good electrical insulation performance;

9. The surface is smooth, without pores, and does not wet with most semiconductor melts.

Properties Of Pyrolytic Boron Nitride:

| Property | Unit | Value | |

| Lattice Constant | μm | a: 2.504 x 10 -10 ; c: 6.692 x 10 -10 |

|

| Density | g/cm3 | 2.10-2.15 (PBN Crucible); 2.15-2.19 (PBN Plates) |

|

| Micro Hardness (Knoop)(ab side) | N/mm2 | 691.88 | |

| Resistivity | Ω·cm | 3.11 x 10 11 |

|

| Tensile Strength | N/mm2 | 153.86 | |

| Bending Strength | ⊥C | N/mm2 | 243.63 |

| ⊥C | N/mm2 | 197.76 | |

| Elastic Modulus | N/mm2 | 235690 | |

| Thermal Conductivity | W/m·k | “a” direction; “c” direction | |

| 200℃ | W/m·k | 60 2.60 | |

| 900℃ | W/m·k | 43.7 2.8 | |

| Dielectric Strength (at room temperature) | KV/mm | 56 | |

Applications Of Pyrolytic Boron Nitride:

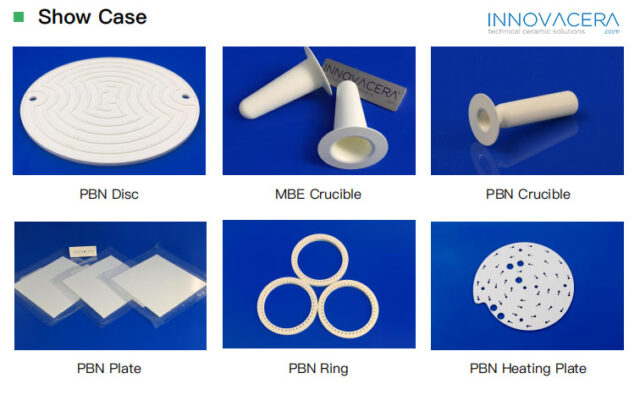

Due to the nature of the CVD process, pyrolytic boron nitride parts typically require wall thicknesses of 3 mm or less. But the CVD process gives pyrolytic boron nitride a nearly perfect layered structure, resulting in anisotropic thermal conductivity, making it an ideal material for making crystal growth crucibles.

1. OLED evaporation unit

2. Semiconductor single crystal growth (VGF, LEC) crucible;

3. Molecular beam epitaxy (MBE) evaporation crucible;

4. MOCVD heater;

5. Polycrystalline synthetic boat;

6. PBN infrared window;

7. Satellite communication microwave tube;

8. PBN coated carrier plate;

9. Insulating panels for high temperature and high vacuum equipment.

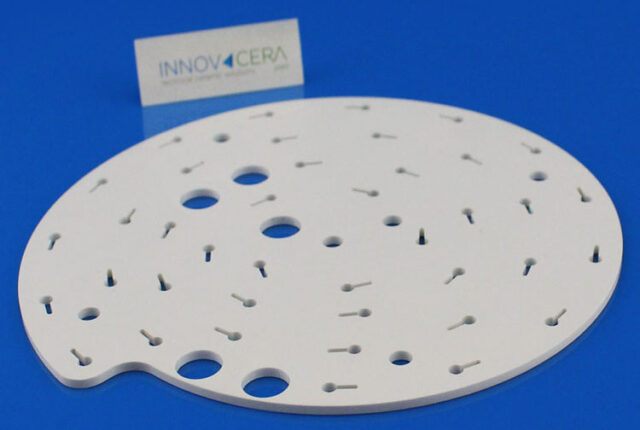

Pyrolytic Boron Nitride Ceramic Processing:

We can meet your advanced ceramic prototyping needs. We are always happy to draw on our many years of experience with advanced ceramics to provide advice on materials, design and application. If you would like to purchase boron nitride plate/rod/tube or custom parts, please contact us and one of our experts will be happy to help you find the solution.

Enquiry

Enquiry