High-temperature zirconia materials, due to their comprehensive “thermal shock resistance,” “corrosion resistance,” “high-temperature strength” and “erosion resistance,” have become key materials for ensuring the safe, efficient, and continuous operation of modern steel continuous casting processes. In particular, their application in core components such as continuous casting nozzles, which control the flow of high-temperature melt, brings benefits such as improved production stability, reduced accident rates, and improved product quality.

Below are some product examples:

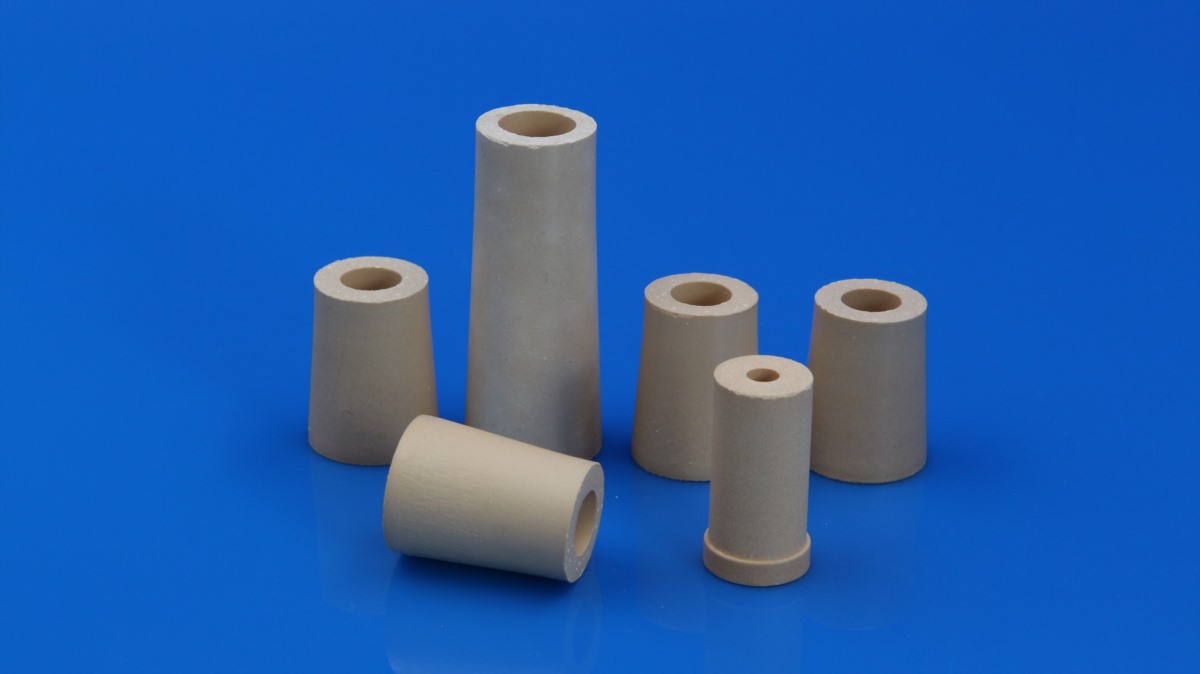

1.Sizing Nozzle: A sizing nozzle is a high-temperature structural ceramic functional device installed at the bottom of the continuous casting tundish. Its main function is to maintain a relatively constant static pressure of molten steel in the tundish. Molten steel flows into the crystallizer via the sizing nozzle. The crystallizer uses high-flow-rate water cooling to remove the heat released during solidification, causing the molten steel to solidify into a billet. Since the heat removed by the crystallizer’s water cooling is limited, the amount of molten steel flowing into the crystallizer per unit time must be within a certain range. The larger the orifice diameter of the sizing nozzle, the greater the amount of molten steel flowing into the crystallizer per unit time. Selecting a suitable orifice diameter to make the tundish nozzle is called a sizing nozzle; it can also be used for flow control of other molten metal solutions.

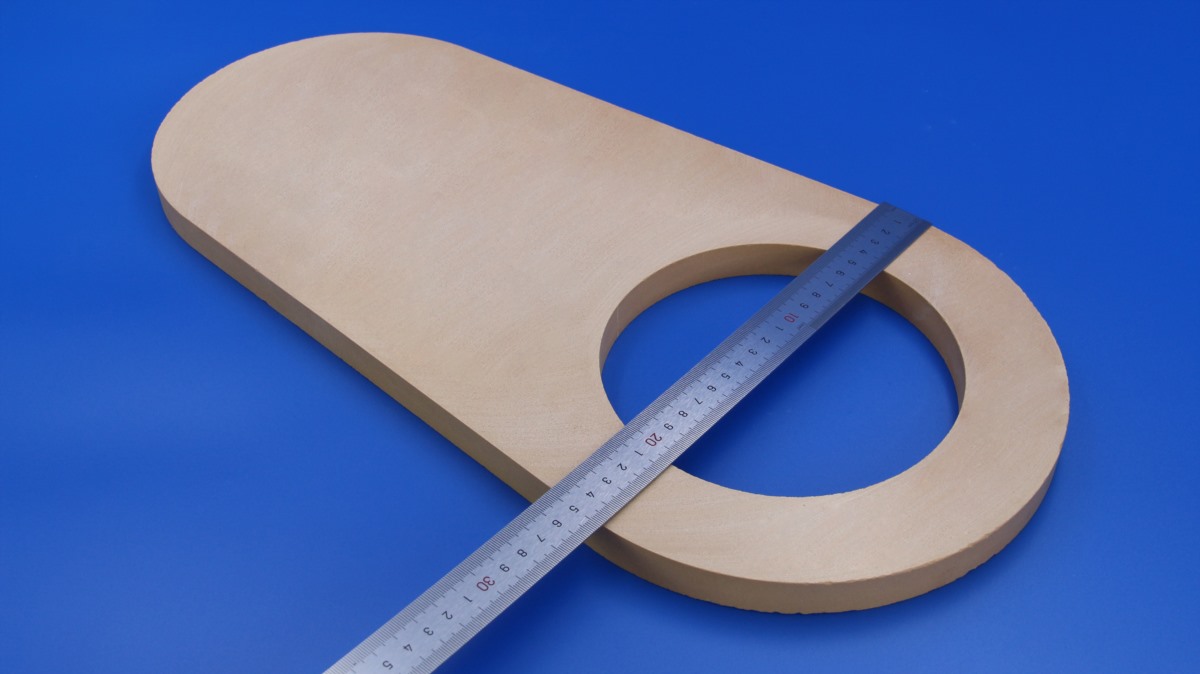

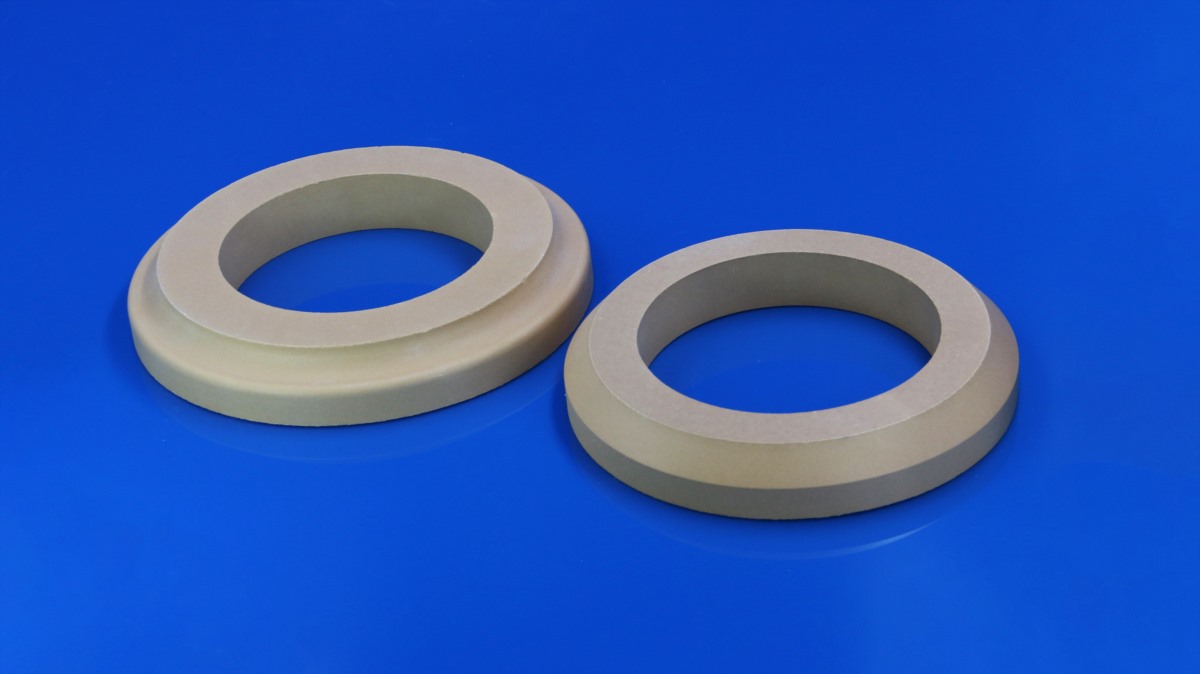

2. The ladle slide plate inlaid with zirconia plates and rings uses a high-temperature adhesive to embed them in the central working area and casting hole of the slide plate. Utilizing the excellent corrosion resistance and erosion resistance of zirconia ceramics, its slow expansion rate increases the surface strength of the slide plate, extends its service life, and reduces costs. It can effectively meet the continuous casting requirements of high-oxygen steel, high-calcium steel, high-manganese steel, and other specialty steels.

3. Converter Slag-Blocking Slide Plate Inlay – Zirconia Plate, Zirconia Ring

Using method: Zirconia rings are inlaid in the upper slide plate, and zirconia plates are inlaid in the lower slide plate.

Advantages:

1) Reduces the amount of slag entering the ladle from the converter;

2) Increases the yield of specialty steels and reduces phosphorus reversion in molten steel;

3) Increases alloy yield, saves on the input of deoxidizers and top slag modifiers, reduces the use of converter auxiliary materials, and saves production costs;

4) Reduces inclusions in molten steel and improves steel purity.

Enquiry

Enquiry