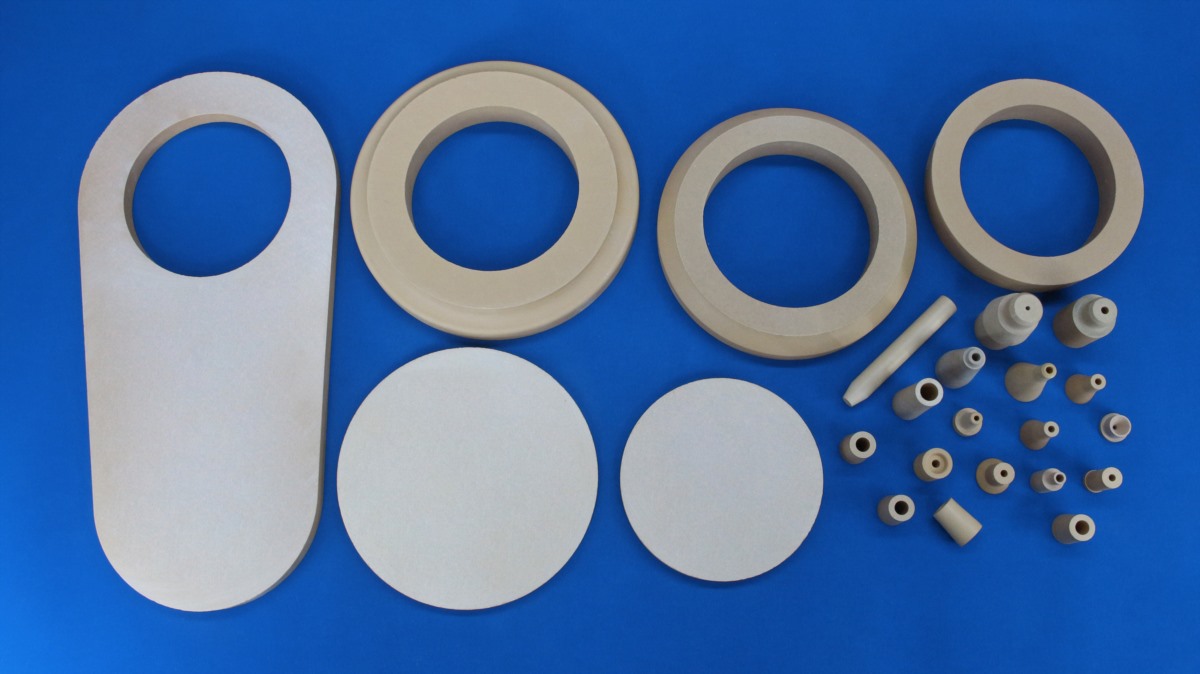

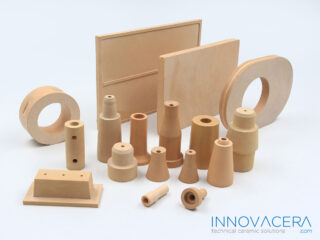

Zirconia ceramic parts, the main components of tundishes in the steel and metallurgical industry

The tundish is mainly used in the steel metallurgical process as a key component of the continuous casting process. Its primary function is to store and distribute molten steel, ensuring a continuous and stable flow from the ladle to the mold.

Main Components of a Tundish

Tundish Body — The main structure that holds molten steel, typically consisting of a refractory lining and a steel shell.

Lining — Includes the working layer in direct contact with molten steel and the permanent layer for thermal insulation. Commonly made from refractory bricks, castables, or spray coatings.

Stopper Rod — A critical part for controlling the molten steel flow rate and regulating the steel level in the crystallizer.

Submerged Entry Nozzle (SEN) — Introduces molten steel into the crystallizer while preventing oxidation and splashing.

Sliding Gate System — Precisely controls the molten steel flow rate, consisting of upper and lower slides and a drive mechanism.

Impact Pad — Reduces impact force during molten steel injection and prevents lining erosion.

Weirs & Dams — Optimize the molten steel flow path and promote the flotation and separation of inclusions.

Tundish Flux / Powder — Prevents oxidation of molten steel and helps retain heat.

Zirconia Ceramic Parts on the tundish

Zirconia ceramic key features include high corrosion resistance, excellent thermal shock resistance, and stability in high-temperature, making it suitable for the following key tundish components:

Shroud Nozzle (SEN) — Requires resistance to molten steel erosion and thermal shock. Zirconia ceramic can extend service life.

Stopper Rod Tip — Directly contacts molten steel and must be resistant to high-temperature erosion. Zirconia ceramic enhances corrosion resistance.

Sliding Gate Plates — Zirconia ceramic provides superior wear and thermal shock resistance against molten steel erosion and mechanical wear.

Impact Pads — Zirconia ceramic is effective in high-erosion areas, extending operational life.

Advantages of Zirconia ceramic

- High-temperature resistance (up to 2000 °C)

- Excellent thermal shock resistance (withstanding severe temperature fluctuations during continuous casting)

- Superior resistance to molten steel and slag erosion (superior to alumina and mullite)

These unique features make Zirconia ceramics an ideal material for key refractory components in tundishes, particularly in the continuous casting of high-end steel grades.

Enquiry

Enquiry