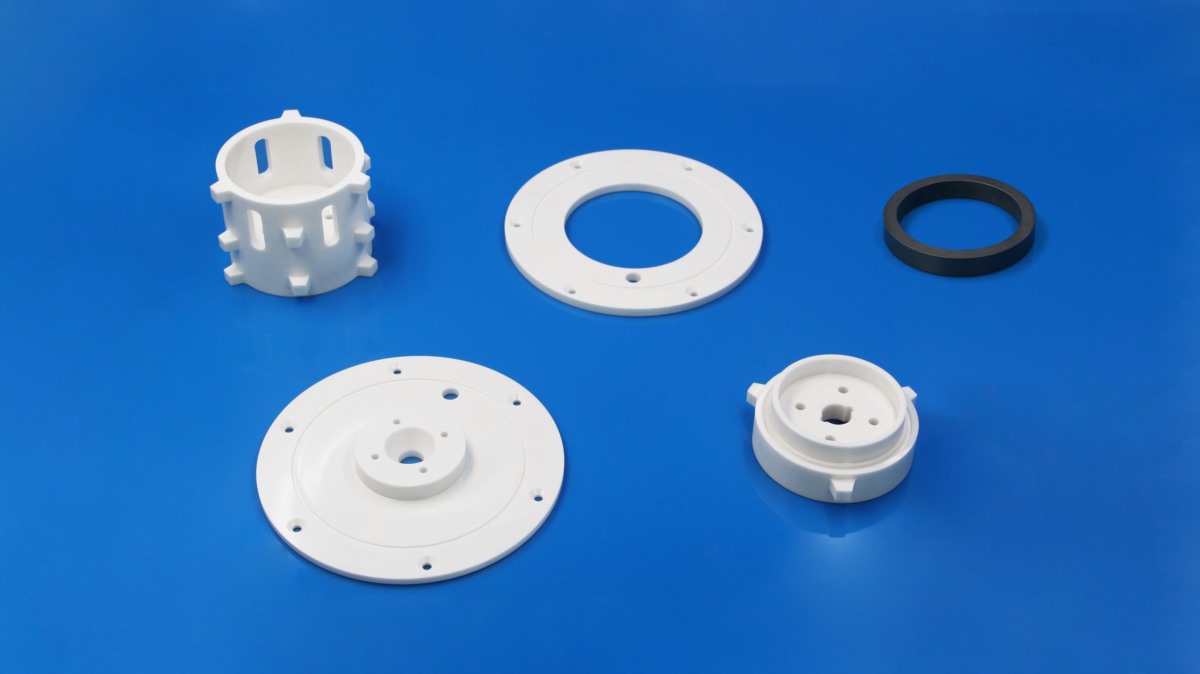

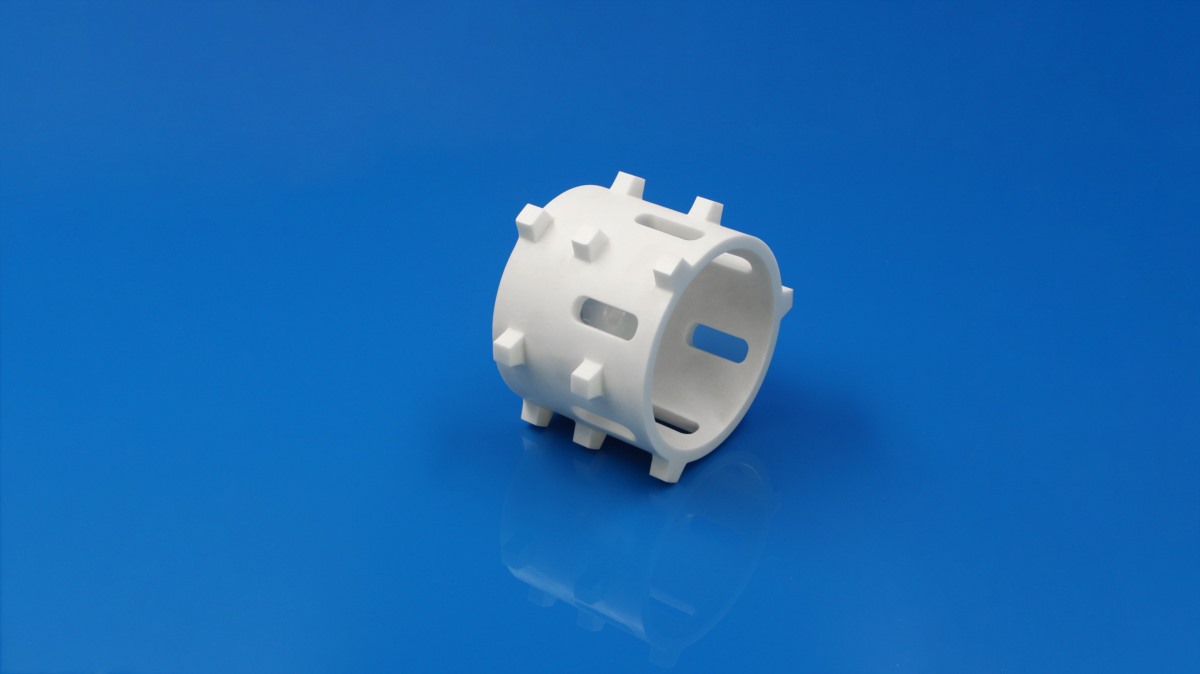

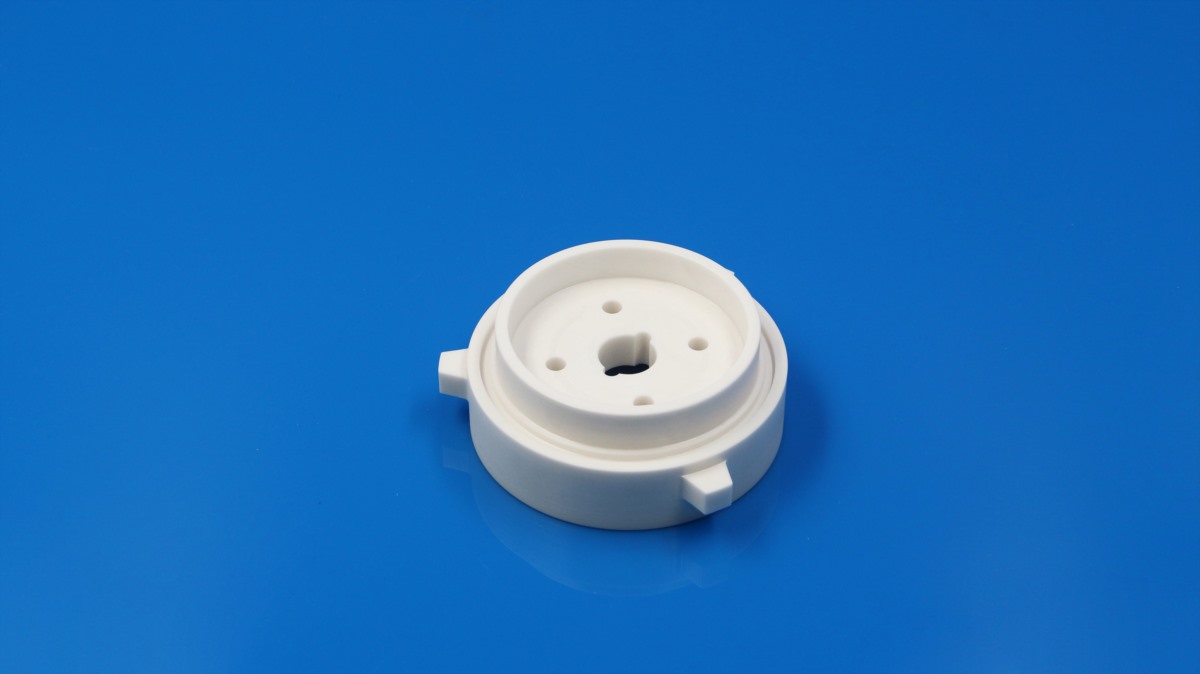

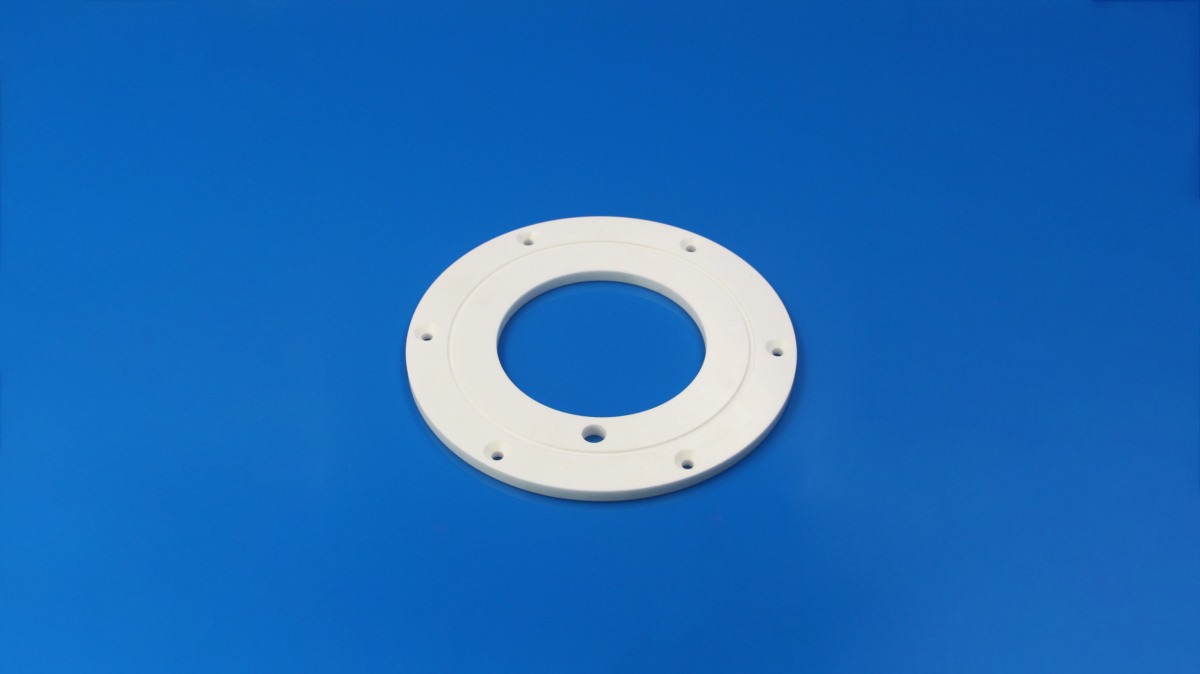

Engineering ceramic components are key components in sand mill equipment due to its high hardness, wear resistance, and corrosion resistance properties. Zirconia (ZrO2) and Silicon Carbide (SiC) ceramic components are used in extreme service which require withstand harsh environments such as high pressure, high speed, and high temperature during the sand grinding process.

Grinding Medium

1.High hardness and wear resistance

2.The optimal combination of various sand grinding equipment applications

3.Improve grinding efficiency

Good grinding results cannot be achieved without a reasonable selection of grinding media. INNOVACERA has a full range of ceramic grinding media.

Application

Paint and Ink: Eater-based nano color paste, ink color paste, silicone color paste, special ink

Industrial Coatings: Water-based industrial topcoat, automotive repair paint, container paint, mechanical topcoat

Printing Ink: Heat transfer ink, inkjet ink, pigment ink, ceramic ink, UV ink

Printing Materials: Flexographic ink, gravure printing ink, cardboard ink, thermosensitive paper pulp

Coating Slurry: Nano alumina slurry, PVDF slurry, slurry, magnesium oxide

Battery Materials: Carbon nanotubes, graphene, lithium iron, nano silica, conductive carbon black

Other industries: Nano new materials, nano, chocolate, additives, ATO, MLCC

Applicable Sand Mill Types

1.Dispersing Disc Sand Mill

Using a static centrifugal discharge device, high flow with high efficiency grinding. It is suitable for chemical production workshops and the products grinding with high output requirements such as agriculture, coatings, paints, inks, which require 3-5 μm grinding.

2.Turbo Nano Sand Mill

Turbo nano sand mill uses a newly designed turbine disperser, it has advantage of high grinding efficiency, large output, and low energy consumption.

3.Rod Pin Nano Sand Mill

Suitable for ultrafine dispersion and nanoscale grinding of water-based and solvent based materials. The structure is stable, the design is exquisite, and the operation is simple. Cleaning, changing colors, and replacing grinding beads are more convenient.

Enquiry

Enquiry