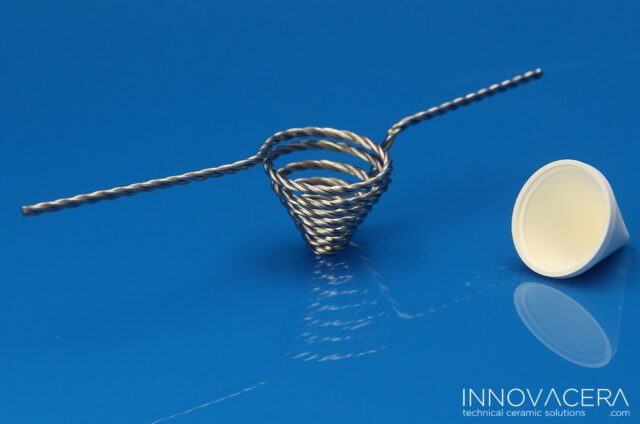

Cynosure Elite Plus Laser Head Cavity Ceramic Laser Cavity Ceramic Reflector

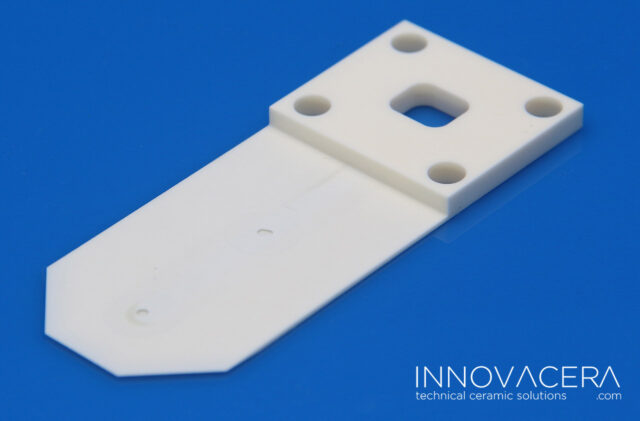

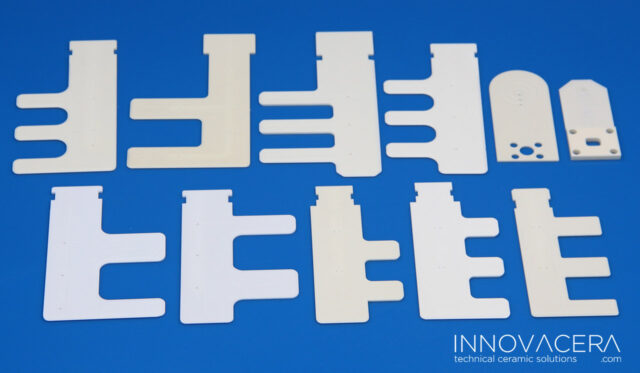

The ceramic laser cavity is a type of laser cavity made from alumina ceramic materials. It is an integral part of a laser system, creating and maintaining the lasing action. Ceramic laser reflectors are high-efficiency diffuse reflectors. Near-perfect diffuse reflection and high reflection efficiency are effectively exploited in laser systems where the pump band of the laser host is in the spectral range of 500 nm to 1200 nm.

Cynosure Elite Plus Laser Head Cavity Ceramic Laser Cavity Ceramic Reflector

Alumina ceramic materials are preferred for laser cavities due to their high thermal conductivity, excellent mechanical properties, and resistance to thermal shock. Innovacera laser reflectors compared to PTFE polymer reflectors, metal reflectors and packed barium powder diffuse reflectors with several desirable characteristics:

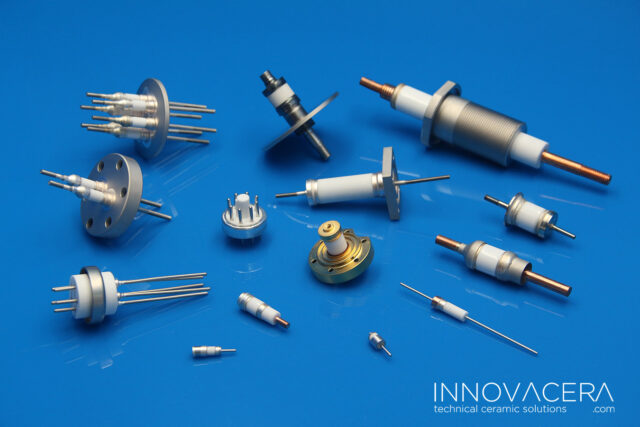

- Efficient reflection eliminates the need for high-precision focusing reflectors

- There will be no coating peeling off like specular metal reflectors.

- Ceramic reflectors are not susceptible to localized catastrophic damage from surface contaminants absorbing radiation.

- The light field inside the cavity is highly uniform and the output beam profile is more uniform.

- Dimensionally stable

- The glass surface is corrosion-resistant and allows direct contact with coolant. The full cavity is easily achieved, so the laser head is simple, compact and low-cost.

- The ceramic material is strong and durable, resisting breakage when the flash explodes.

- Long operational lifetime

- High laser output

Ceramic laser cavities are widely used in various applications, including materials processing, laser cutting, medical lasers, scientific research, and defense systems. Their excellent thermal and mechanical properties make them suitable for high-power laser operation while maintaining stability and longevity.

Enquiry

Enquiry