Innovacera manufactures custom and standard ceramic reflector designs for hair removal lasers markets. There are some systems for use with hair and tattoo removal:

1). Intense Pulsed Light (IPL)

Common Names: PhotoDerm, EpiLight, Quantum, Aculight, Vasculight

2). Diode Laser

Common Names: SLP, F1 Diode, LightSheer, MeDioStar, SopranoXL, LaserLite, Epistar, Apex

3). Nd: Yag

Common Names: CoolGlide, Medlite IV, Varia, Athos, Lyra, Sciton Profile, Image Cutera, Cynosure Elite, Candela, GentleYAG

4). Alexandrite laser

Common Names: Candela, GentleLase, Cynosure Apogee, EpiTouch Plus

5). Ruby laser

Common Names: RubyStar and Palomar E2000

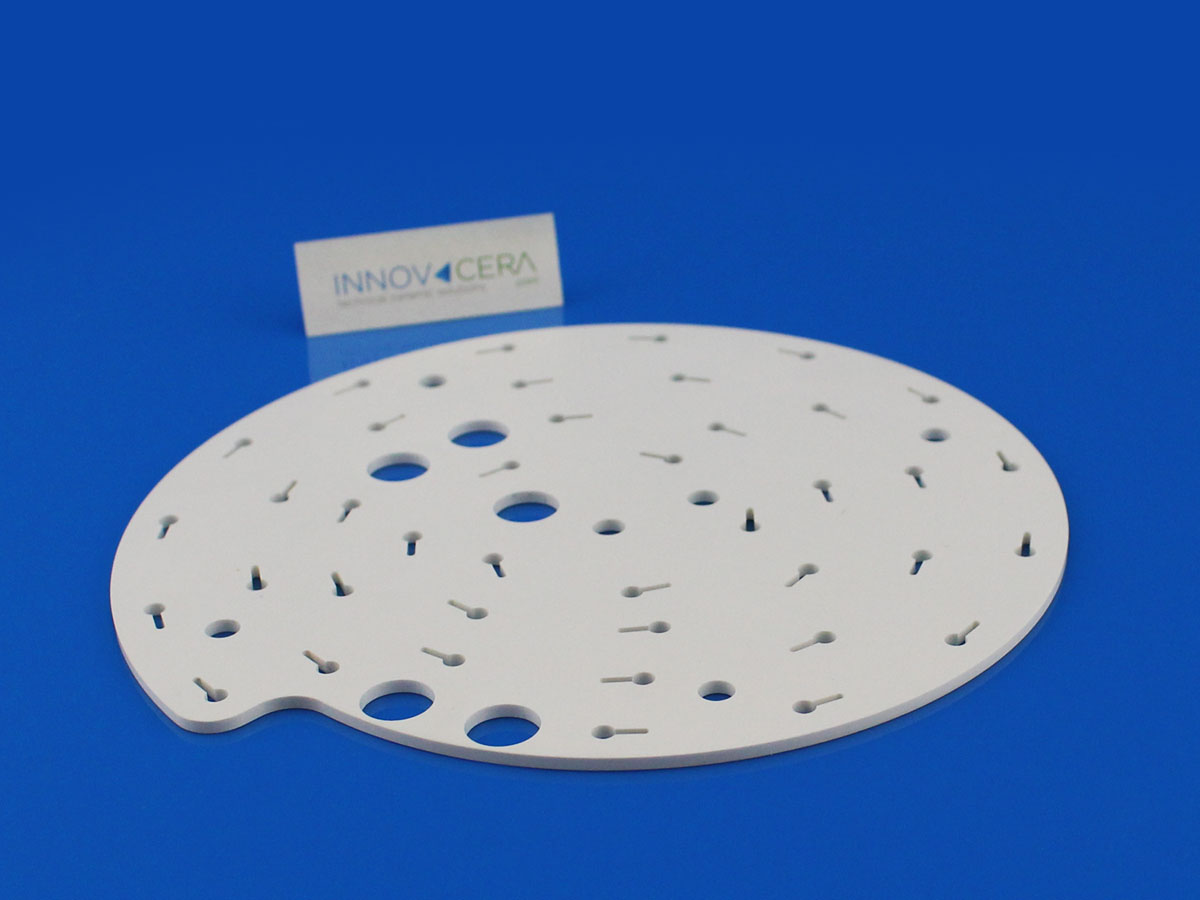

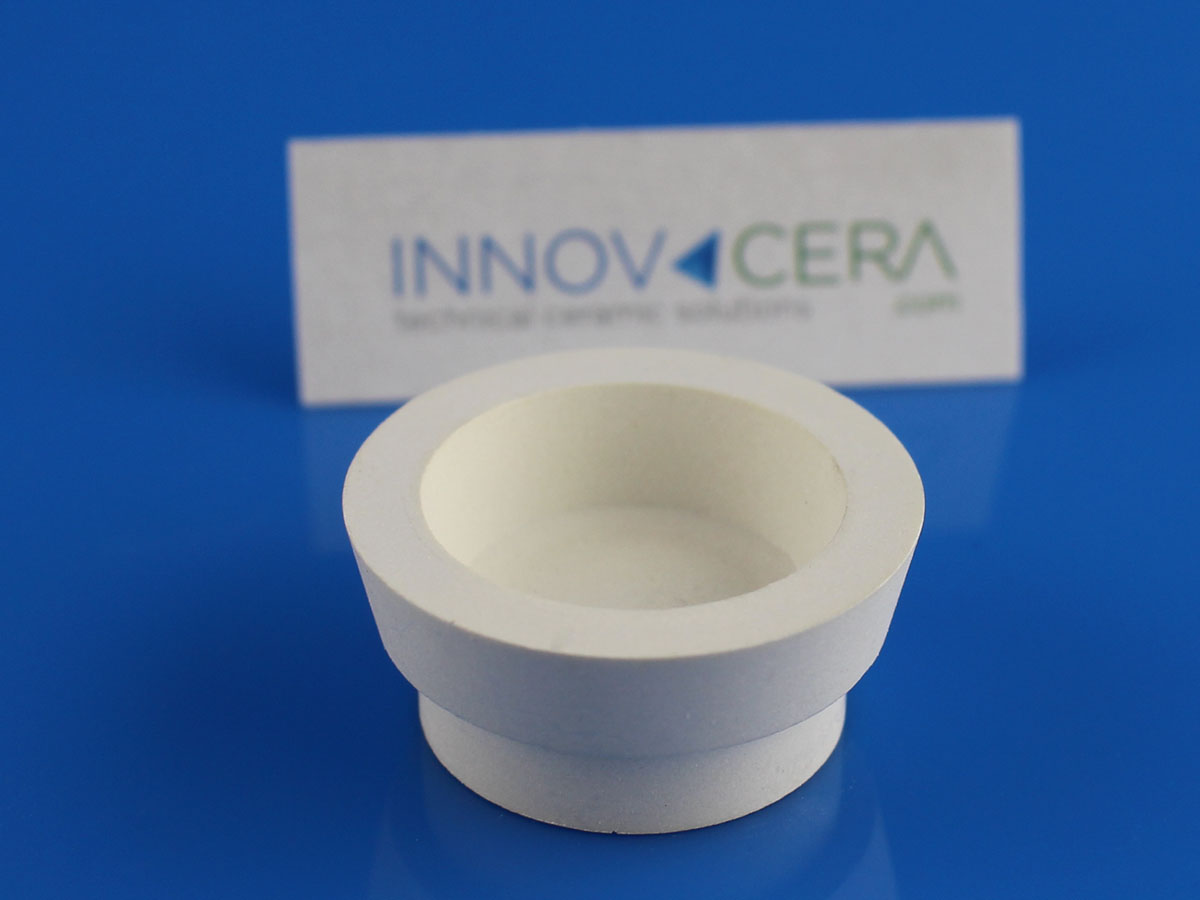

Ceramic Reflector is made by high purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity.

Ceramic Reflector material properties::

- Bulk density (fired): 3.1 g/cm3

- Porosity (apparent), nominal: 22%

- Flexural strength (ASTM C1161, 3-point): 170 MPa

- Thermal expansion coefficient:

200-500℃, 7.9*10-6/C

200-1000℃, 9.0*10-6/C

Ceramic Reflector features:

- Compared to metal reflectors, ceramic units offer higher reflectivity and therefore enhanced laser power.

- Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk reflectivity

- Resists chemical attack

- Controlled porosity

- Has high strength

- Good thermal conductivity

- High electrical resistivity

We can machine or grind ceramic reflectors against the customer’s drawings. Quantities range from prototype to production quantities. Glazing protects the surface in preventing adhesion of impurities and primarily ensures leak tightness of the reflectors.

Enquiry

Enquiry