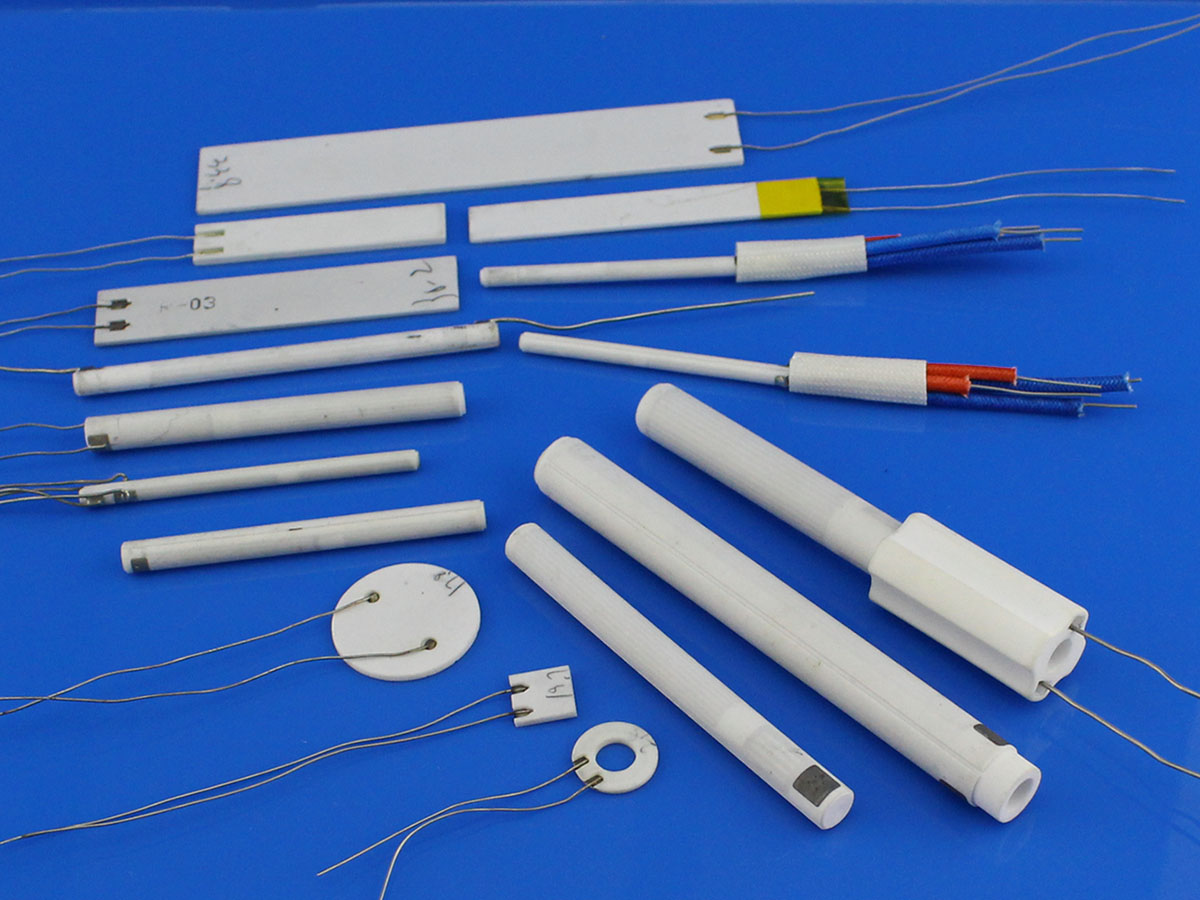

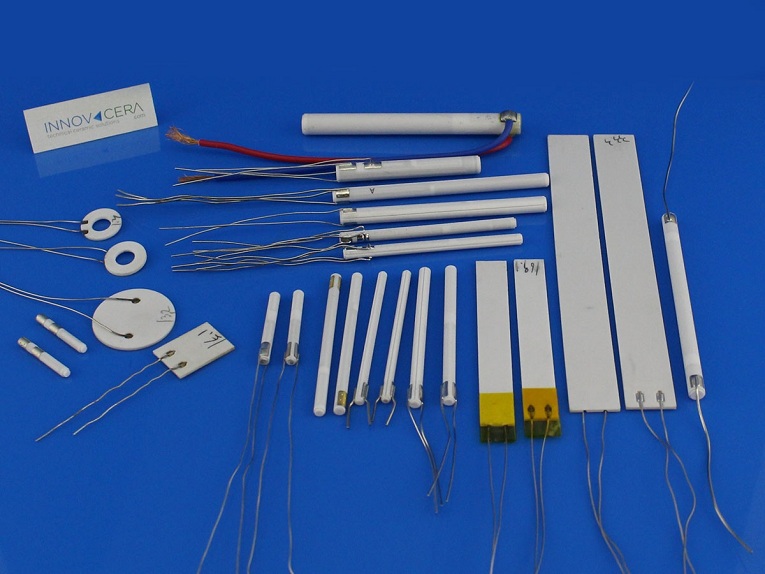

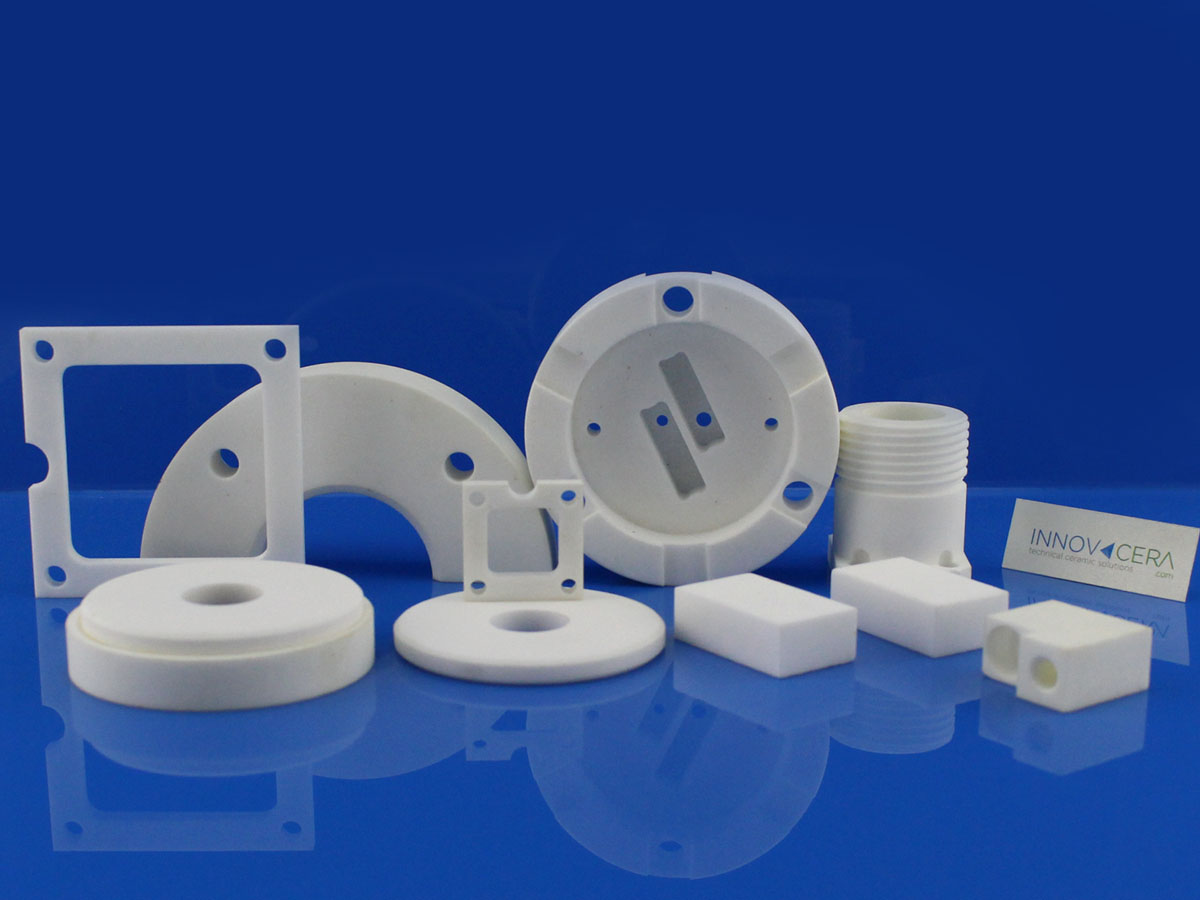

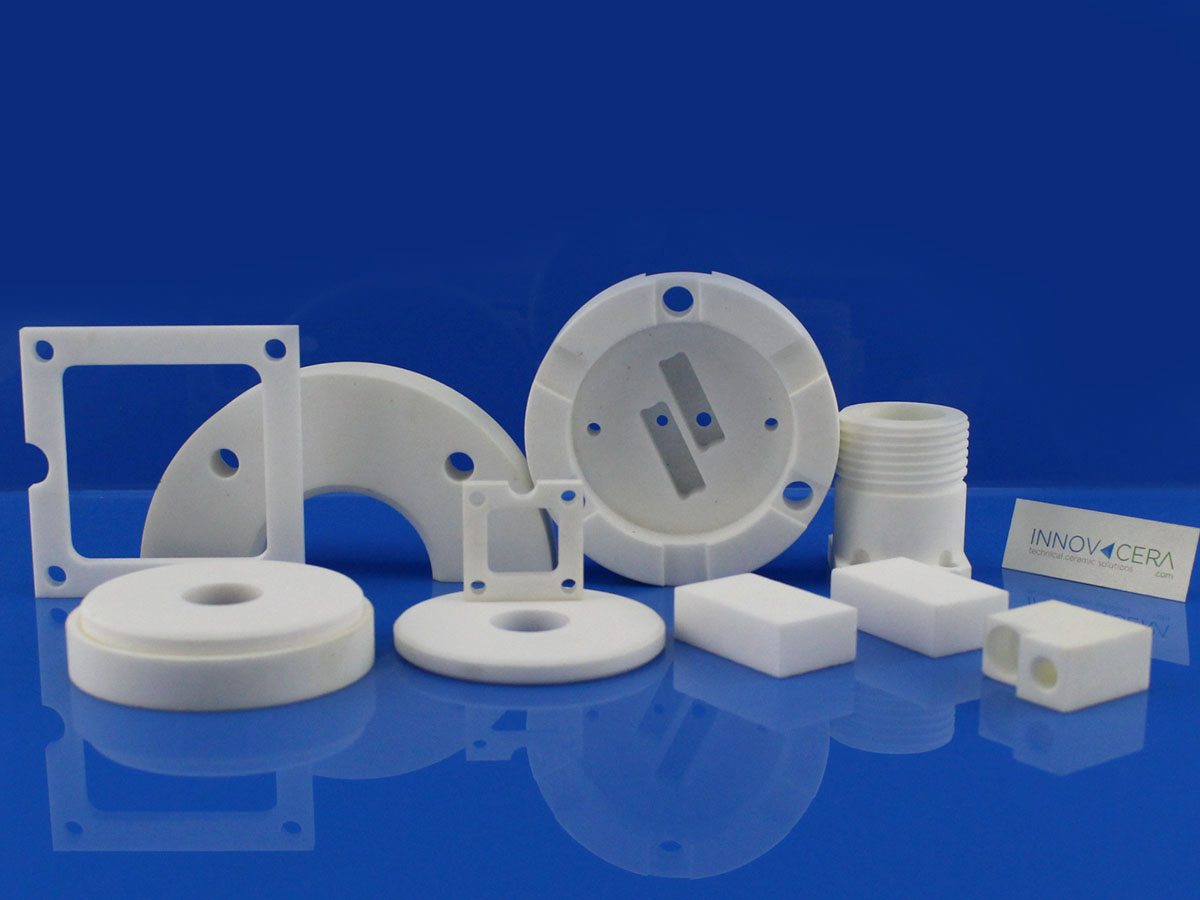

Thick film metalizing ceramic parts

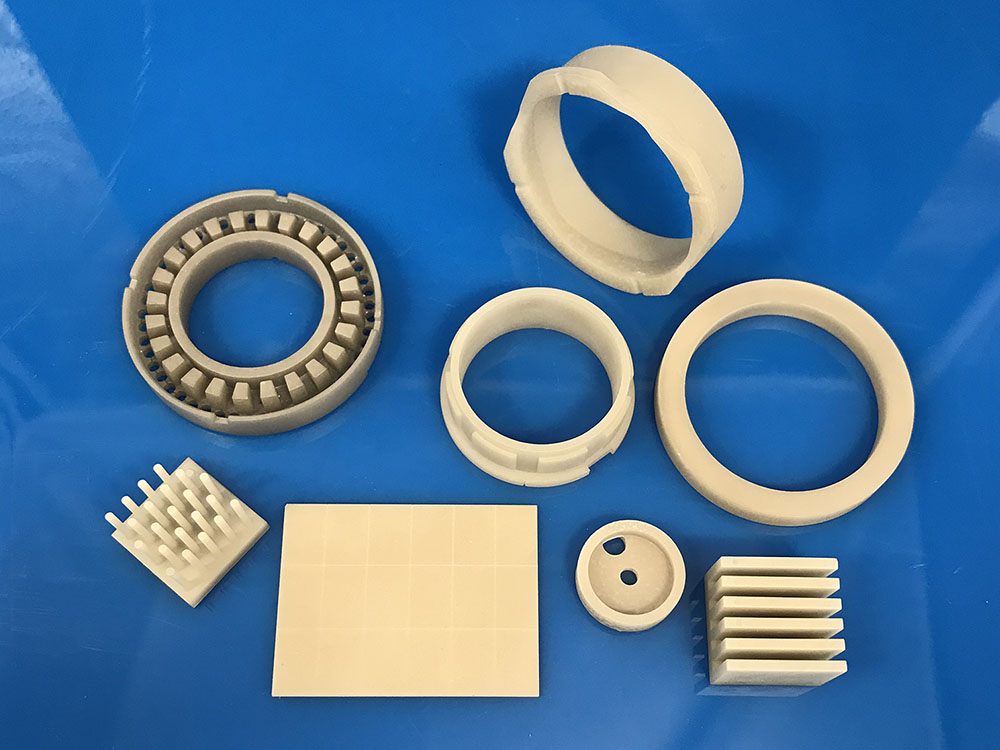

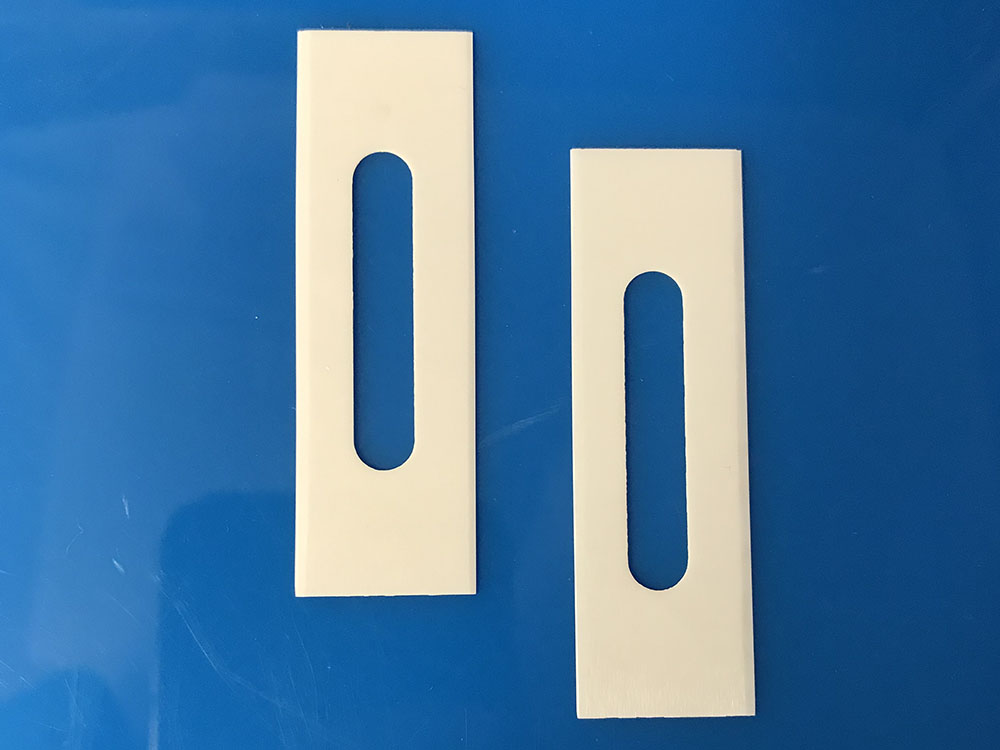

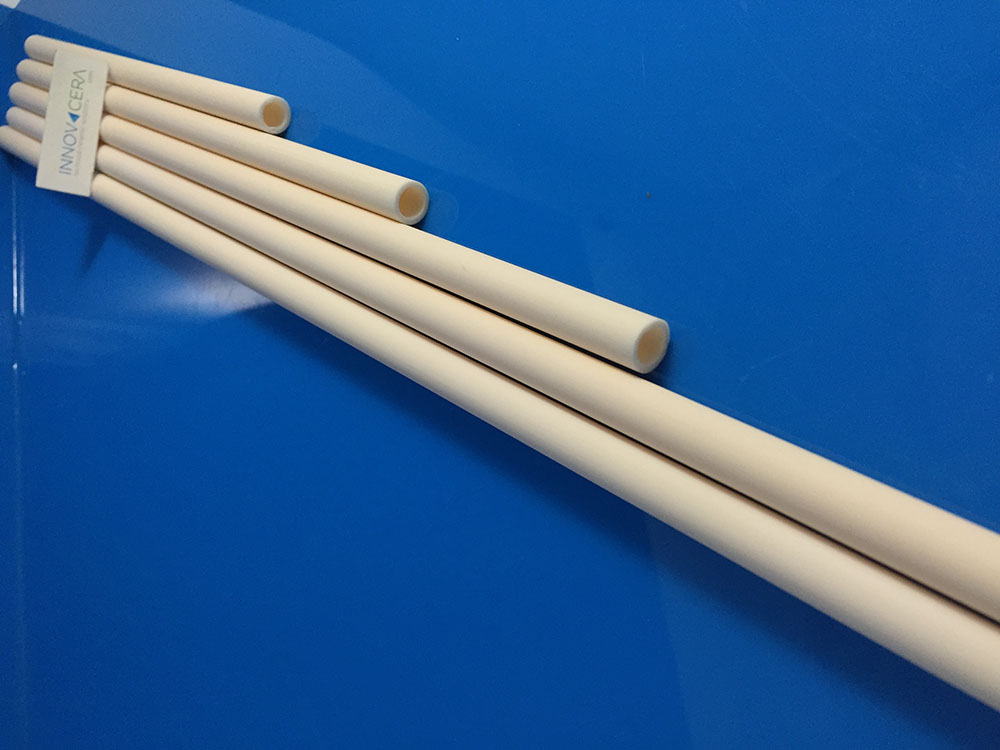

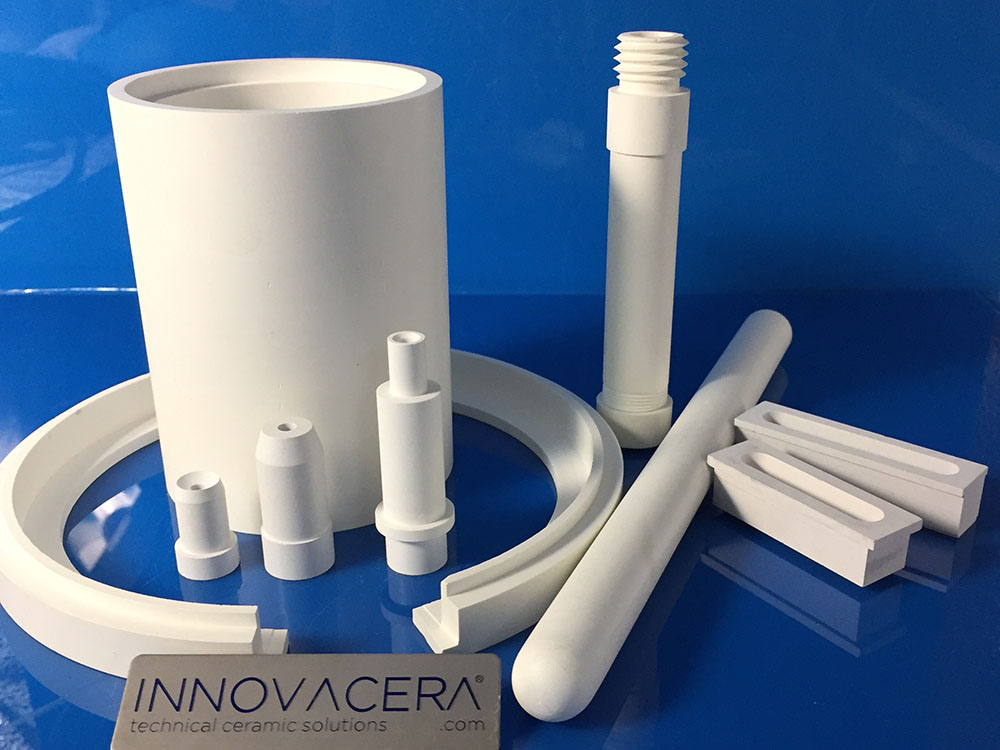

Xiamen Innovacera Advanced Materials Co., Ltd can provide thick film metalizing ceramics.

The ceramic parts do metalized coating or plating. Thick film coatings include Molybdenum-Manganese (Mo-Mn) providing excellent adhesion to ceramic parts. This can be followed by a barrier diffusion layer of electrolytic pure Nickel (Ni). The third layer of gold (Au) or other precious metal, results in a tightly sealed ceramic to metal assembly ready for the soldering or brazing process.

For more details, please contact us

Enquiry

Enquiry