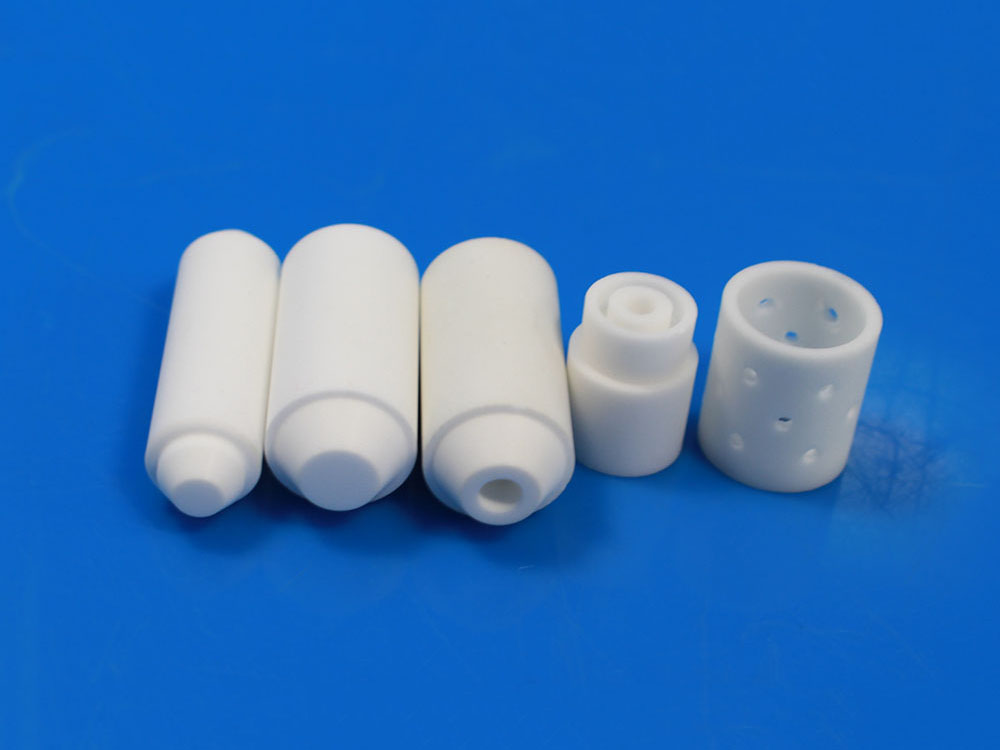

Boron Nitride Crucibles With Adapter For Melt Spinning

This is the high purity Boron Nitride crucible with adapter suitable for melt spinning:

– Nonferrous & ferrous metals such as Al, Bi, Ge, Sb, Sn, Cd, Pb, Ni, Zn, Cu, Mg, Im, Fe, Stainless Steel…

– Glass melt, Soda glass, Cryolite

– Silicon molten salt, fluoride, slag

Advanced Features

Excenllent thermo-shock resistance

Superior electric resistivity

Corrosion resistant (acid and alkali resistant)

Attentions

Max. working temperature in the air is 900°C

The crucible shall be stored in the dry environment inside a sealed container

Never wash the crucible with water. Use fine sandpaper or cloth to remove any dirt or residues

Not suitable for use with Sb2O3, chromium oxide, molybdenum trioxide, arsenic trioxide, titanium carbide, high lead glass glaze, boron phosphate, potassium phosphate, chlorine.

Enquiry

Enquiry