Innovacera® Valveless ceramic metering piston pumps For H2O2

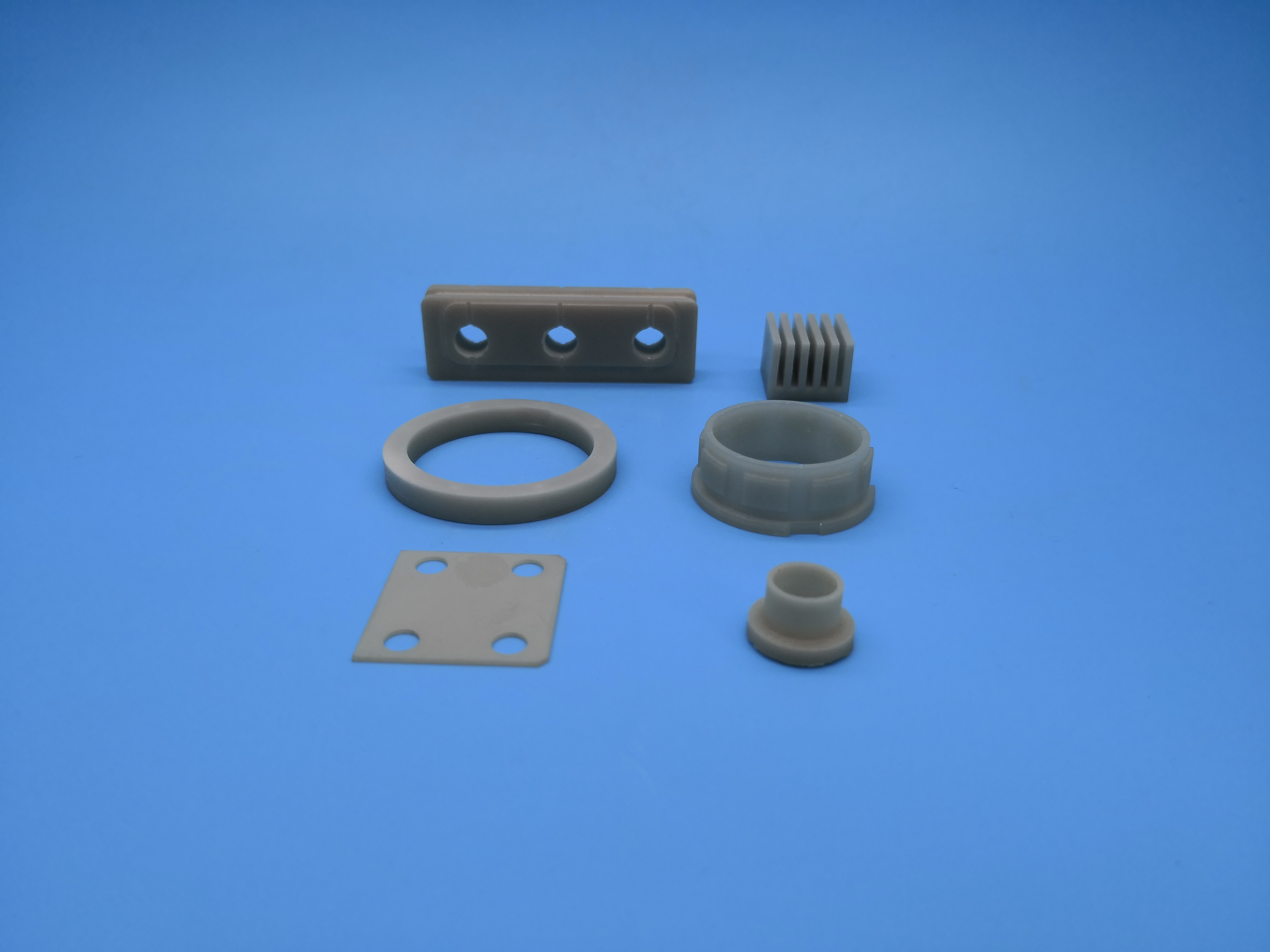

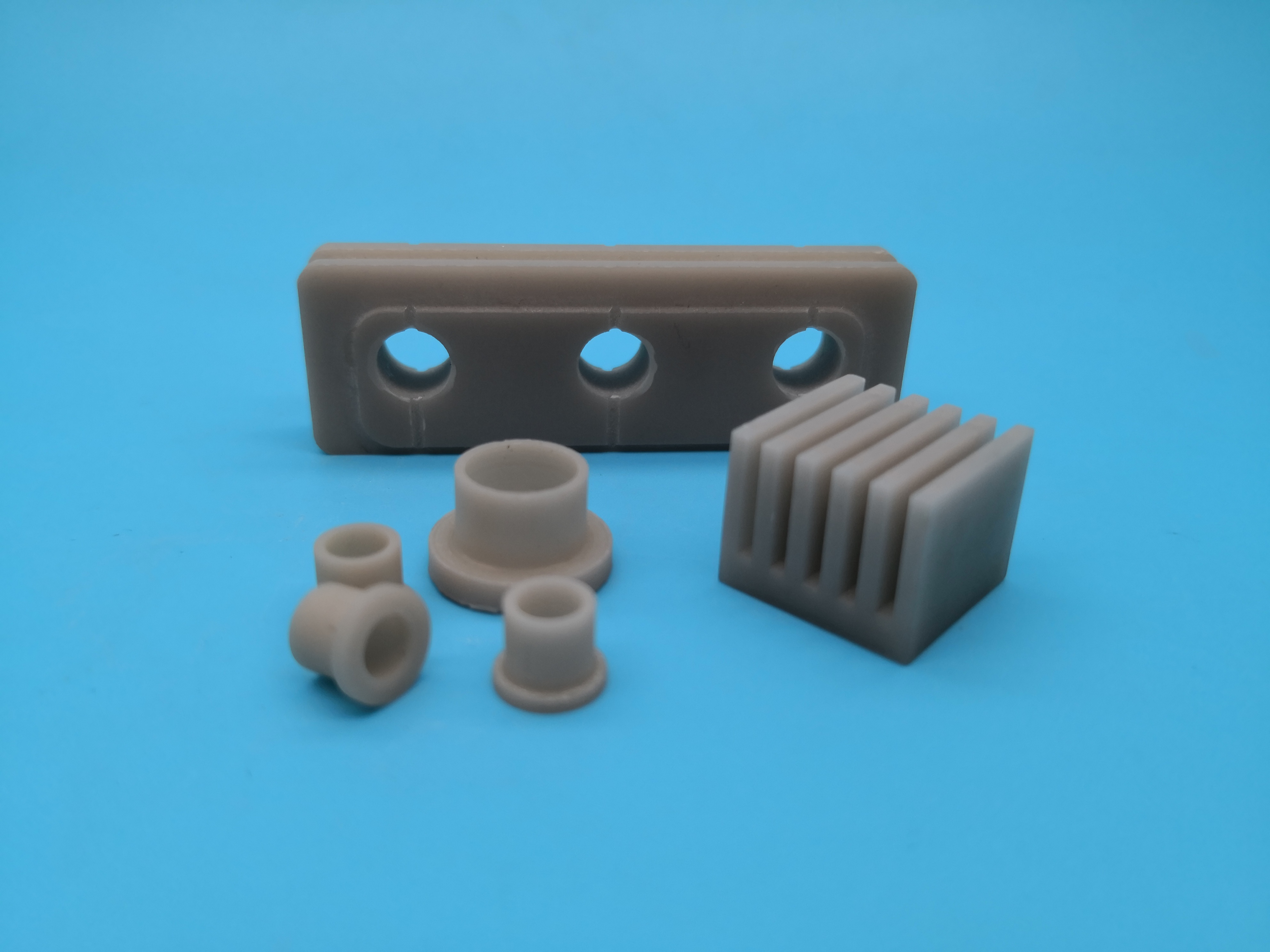

Innovacera provides advanced ceramic solutions for fluid dispensing and filling in the pharmaceutical, cosmetic and food industries. Our ceramic filling pumps types are valveless ceramic metering piston pumps and valve ceramic piston pump.

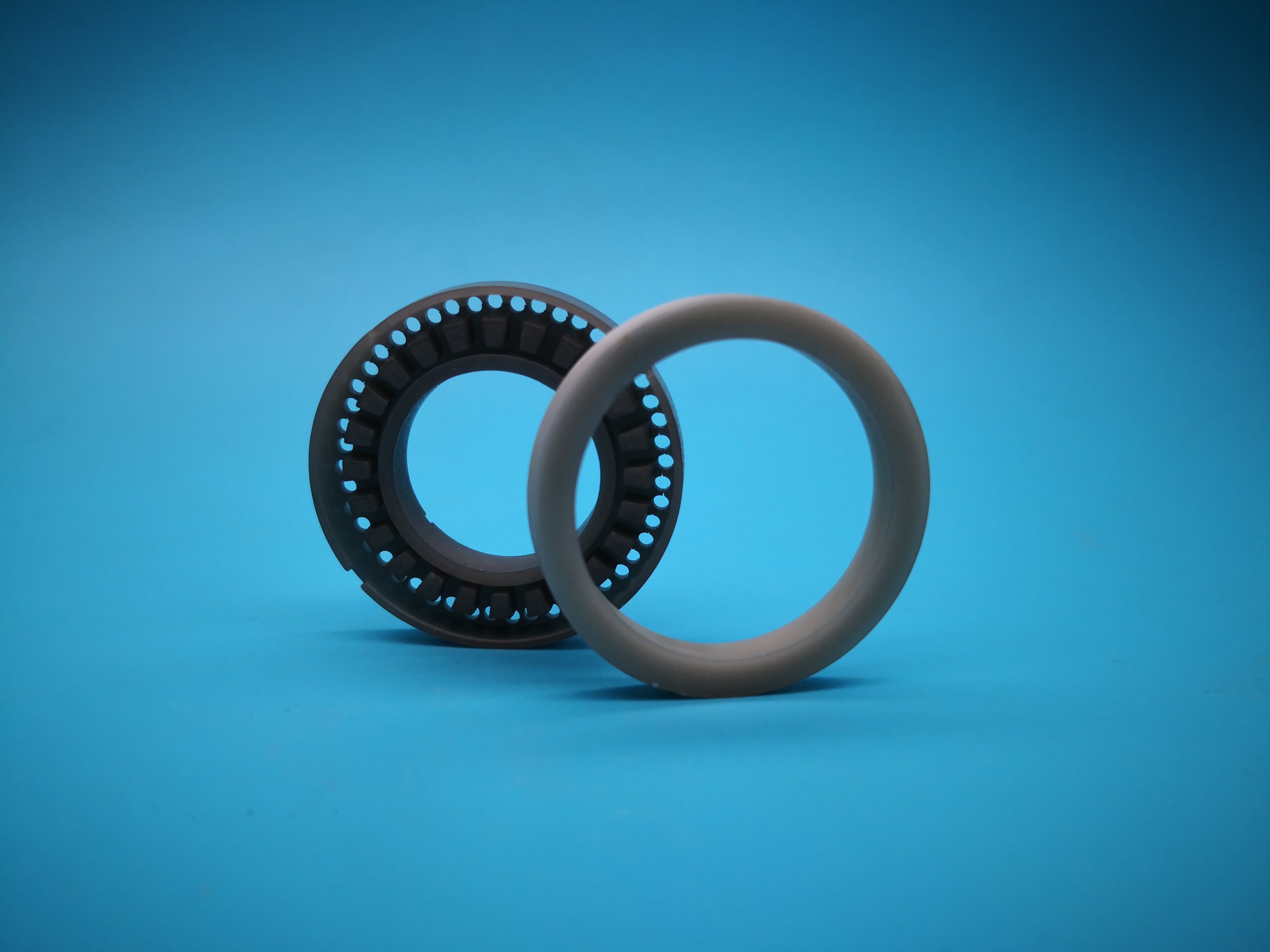

In pharmaceutical and medical applications, vaporized hydrogen peroxide is a low-temperature sterilization method used to decontaminate everything from components and instruments to entire laboratories, clean rooms, and hospital operating rooms.

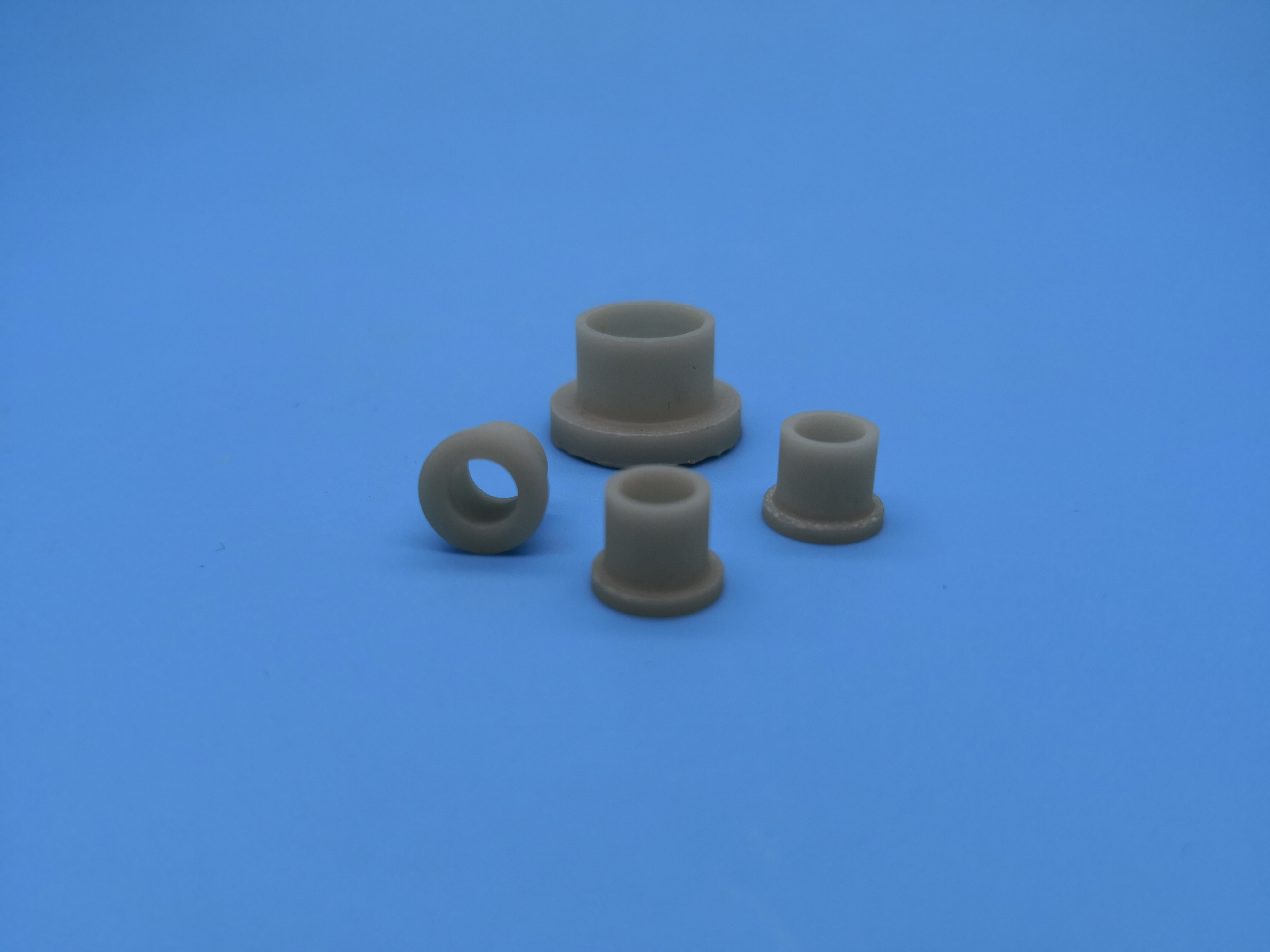

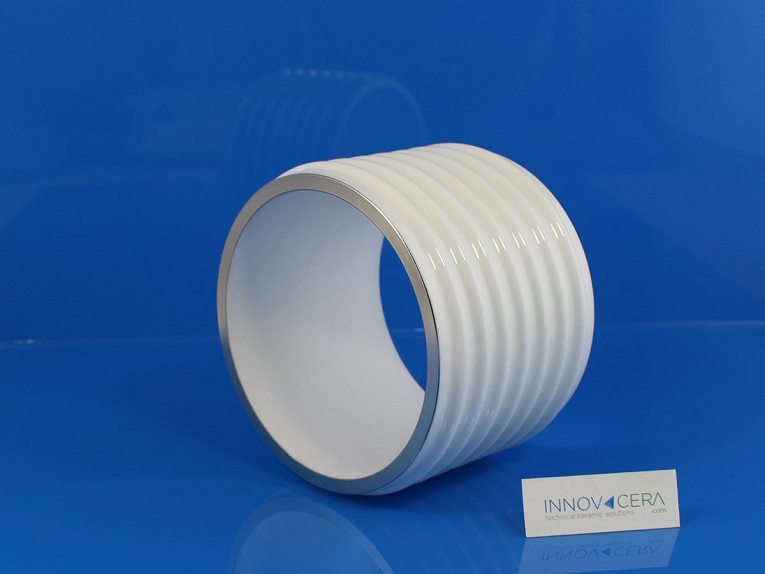

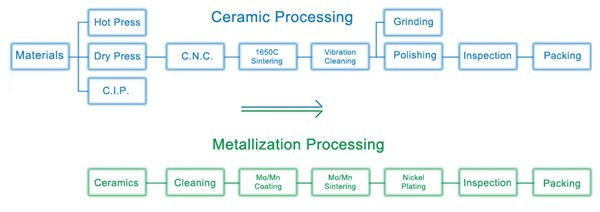

Valveless ceramic metering piston pumps only have a ceramic piston moving part contacting with the fluid. The ceramic piston is made by alumina ceramic or zirconia ceramic which have chemically inert, wear-resistant, and dimensionally stable. IT accomplishes both the pumping and valving functions resulting in a unique design that eliminates all check valves. It also provides maintenance-free operation for millions of cycles, at a precision of 0.5% or better without the need for recalibration.

Hydrogen peroxide (H2O2) is used in many foods, pharmaceuticals, and medical applications as an effective sterilizing agent. Dispensing of H2O2 is critical to container sealing during the aseptic packaging process for a variety of food products.

According to the above advantages, Innovacera Valveless ceramic metering piston pumps are suitable for OEM sterilization equipment and it is widely used for hydrogen peroxide metering.

Enquiry

Enquiry