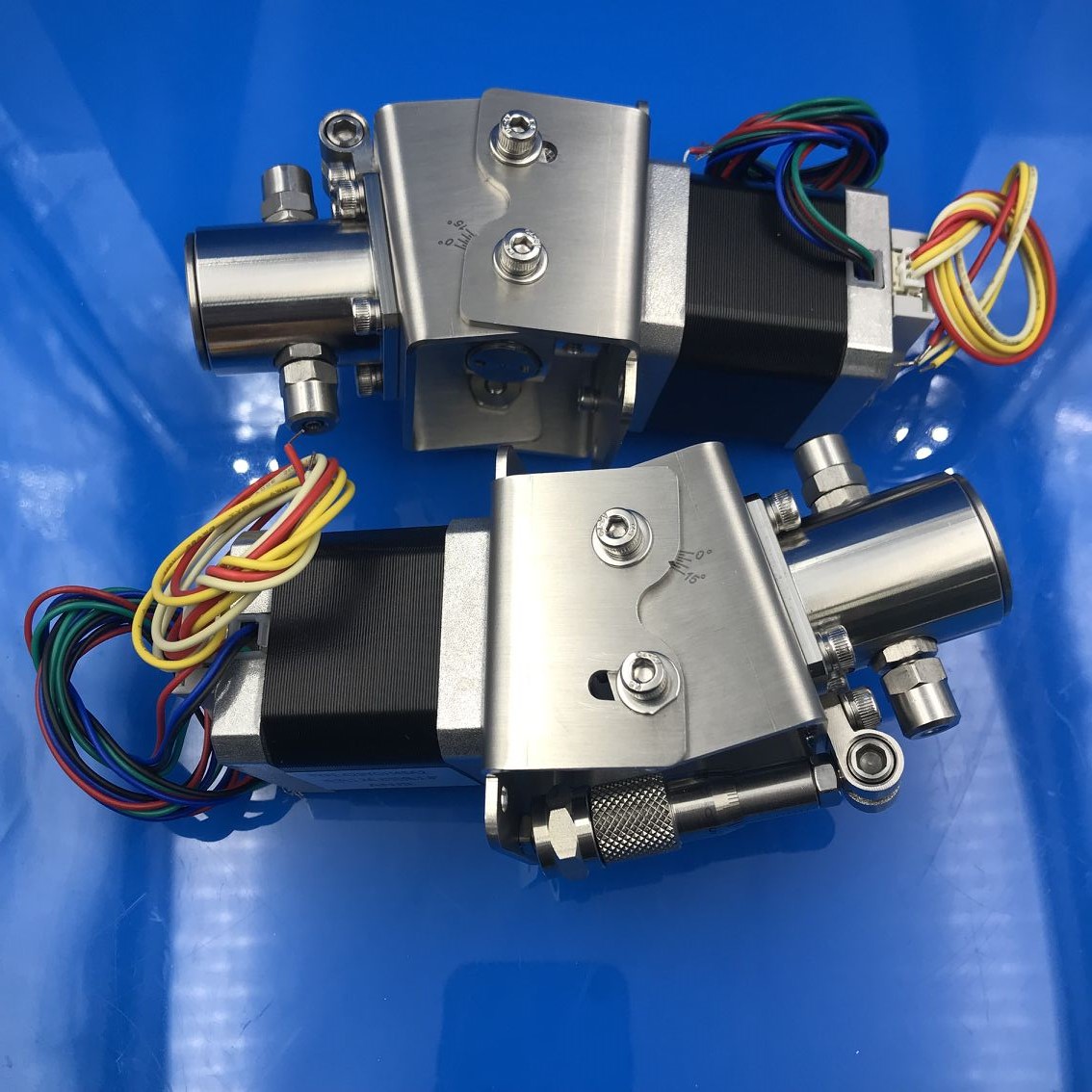

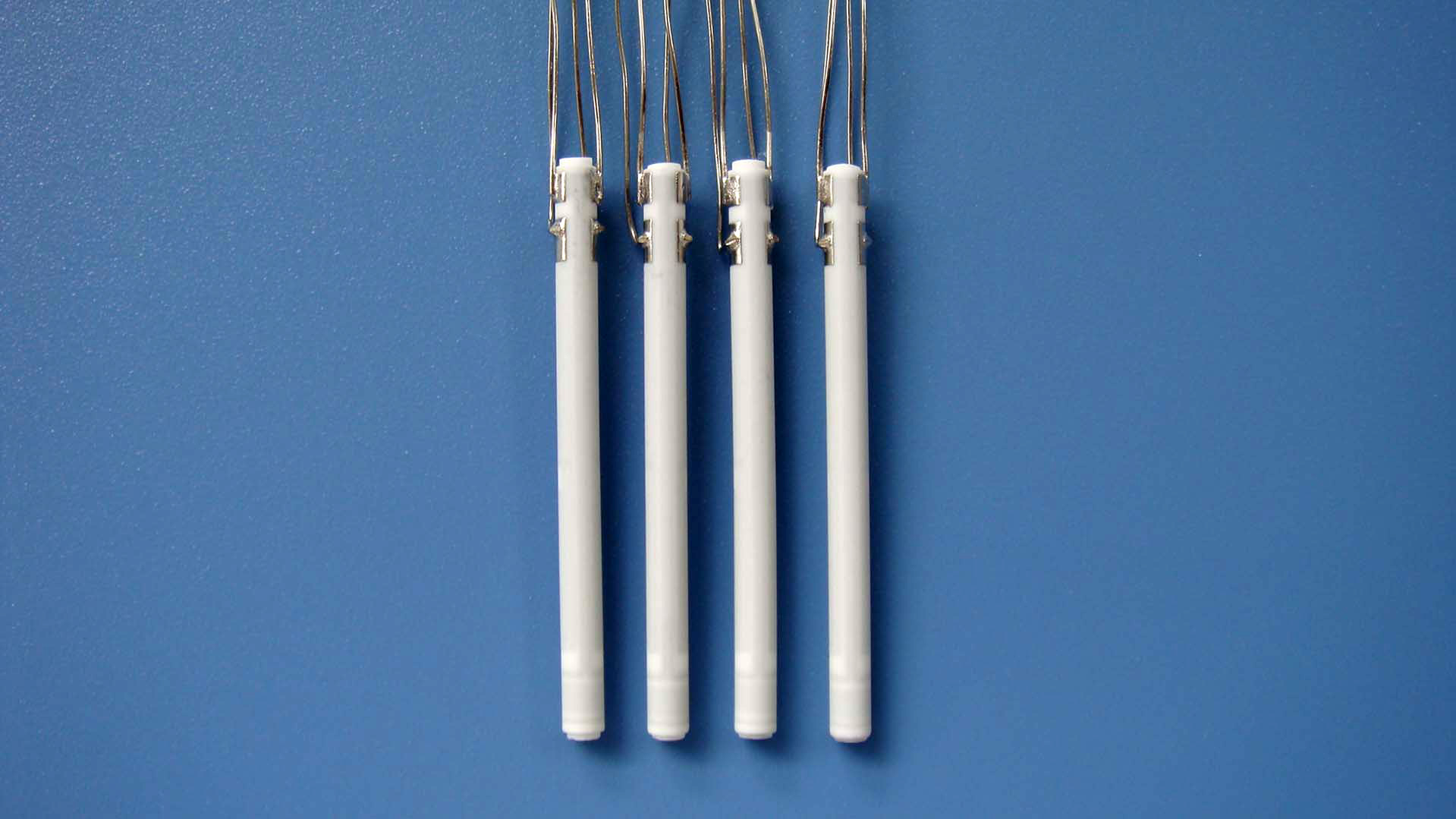

Innovacera Ceramic Valveless piston pump

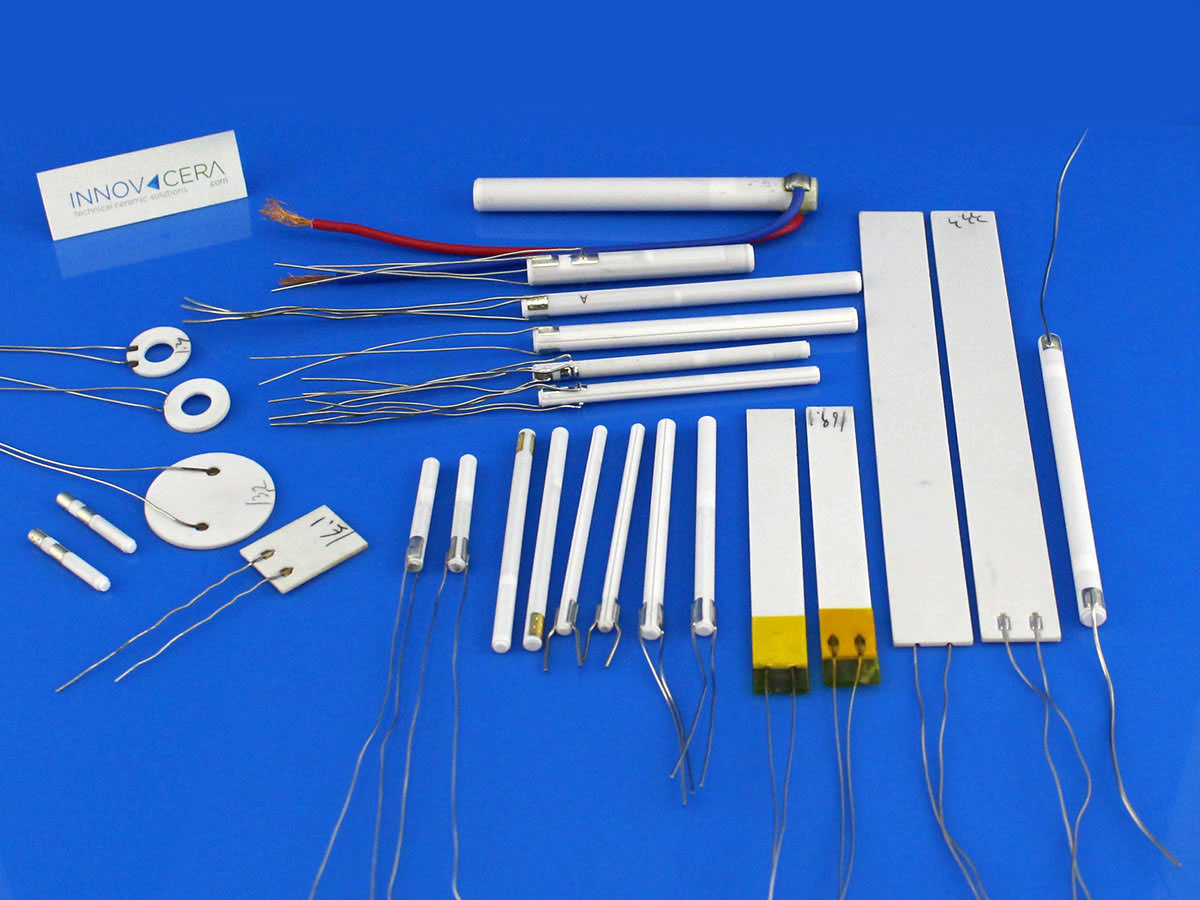

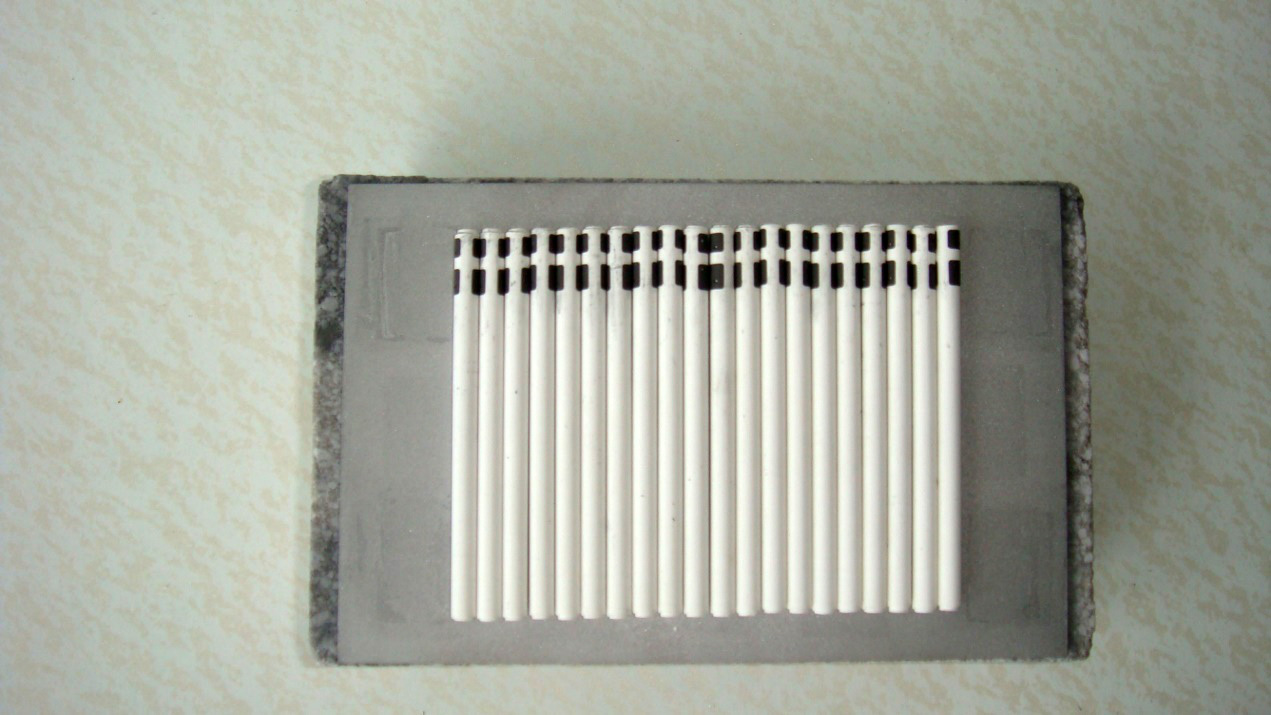

Ceramic valveless piston pump characteristics:

1. Extremely inert chemical stability, acid and alkali resistance, corrosion resistance, and high-temperature resistance.

2. super hard, wear-resistant, particle release is very small, long service life.

3. the material is dense, the water absorption rate is lower than zero; the surface finish is extremely high, the friction is extremely small; the material residue is extremely small.

4. the coefficient of thermal expansion is very small, the piston fits better, the filling machine has higher precision, and can be cleaned and sterilized online.

Application areas:

1. Research institutes, laboratories, universities, pharmaceutical factories, hospitals, cosmetics, etc.

2. widely used in the pharmaceutical, pharmaceutical, food, chemical, cosmetics industry, precision quantitative filling.

3. for the precise quantitative filling of blood, biological reagents, oral liquid, injection, high-grade cosmetics, essence, fungicide and other liquids.

4. Precision quantitative filling for various acid-alkaline corrosive liquids.

Video content:

How to Disassemble Ceramic Valveless Piston Pump?

How to Assemble Ceramic Valveless Piston Pump?

How does Ceramic Valveless Pump work?

Enquiry

Enquiry