Innovacera Ceramic Thermally Conductive Interface Pads are designed to provide a preferential heat-transfer path between heat-generating components, heat sinks, and other cooling devices. The pads are used to fill air gaps caused by imperfectly flat or smooth surfaces which should be in thermal contact. The pads are made of ceramic materials such as alumina ceramic and aluminum nitride, which help in providing enhanced thermal conductivity and excellent insulation performance. Typical applications include Power Devices, Integrated Circuit (IC) chip packaging heat conduction, MOSFET Transistor, IGBT Transistor Heat Sink, MOS Transistor, heat sink interface, LED board Thermal Interface Material (TIM), Chip ON Film (COF) heat conduction.

TO-3P-220-247-254-257-258-264 Aluminum Nitride Ceramic Thermal Pads Without Hole For MOSFET Transistor IGBT Transistor Heat Sink

A ceramic heat sink is a device that dissipates heat-dissipating electronic components in an electrical appliance.

The whole structure of the ceramic heat sink increases the heat dissipation area in contact with the air, which greatly enhances the heat dissipation effect, and the heat dissipation effect is better than that of the super copper and aluminum.

Ceramics are insulated, resistant to high temperatures, oxidation, acid and alkali, cold and thermal shock, and low coefficient of thermal expansion, ensuring stability in high and low temperatures or other harsh environments.

Ceramics can withstand high current, can be high voltage, can prevent leakage breakdown, no noise, will not generate coupling parasitic capacitance with power tubes such as MOS, and thus simplify the filtering process.

Aluminum nitride ceramic thermal insulator pads are ceramic materials with outstanding properties such as high thermal conductivity and high electrical resistance. In addition, it is featured advantages such as high hardness, corrosion resistance, low dielectric constant and dielectric loss, and low CTE. Aluminum nitride ceramics have excellent thermal conductivity (7-10 times that of alumina ceramics), as the thermal expansion coefficient of silicon is similar, as a new generation of ceramic materials, more and more people pay attention to it.

Ceramic Thermal Pads Installation Steps:

①Clean the target surface: Clean the dust or stains on the surface of the object to be installed, and then align the hole position of the ceramic insulating sheet;

②Power tube bonding: Stick the power tube on the ceramic insulating sheet;

③Fixed the insulation sheet: Use screws to fix the power tube and ceramic insulating sheet on the installation object.

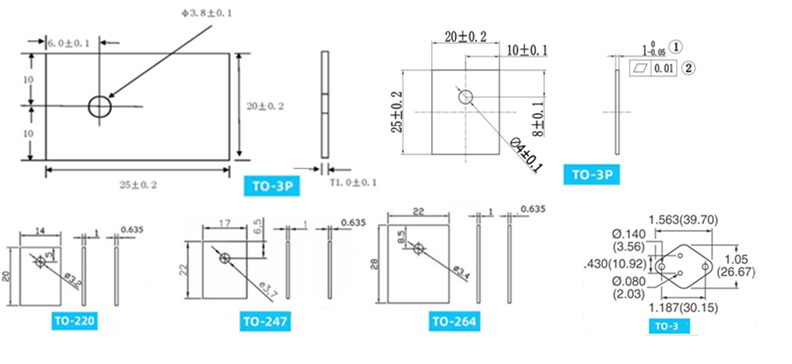

Regular Size:

For Package Type: TO-3P / TO-220 / TO-247 / TO-264 / TO-3/TO-254/TO-257/TO-258, With Hole or Without Hole.

TO – 3P, 25*20*1mm (other thickness is available, too);

TO-220, 20*14*1mm (other thickness is available, too);

TO-247, 22*17*0.635mm (other thickness is available, too);

TO-264, 28*22*1mm (other thickness is available, too);

TO-3, 39.7*26.67*1mm (Rhombus shape).

TO-254, 34*24*1mm (other thickness is available, too);

TO-257, 40*28*1mm (other thickness is available, too);

TO-258, 50.8*50.8*1mm (other thickness is available, too);

Other standard sizes:

25.4*25.4mm;

114.3*114.3mm;

152*152mm;

190.5*138mm…..;

Customized sizes are available.

Regular Size drawing:

Machine detail:

| Technology data | Name | Technology requirement | Remark |

| 1 | Machine size | Thickness | as per drawing |

| 2 | Flatness | 0.01 | |

| 3 | Camber | ≤2‰ | |

| 4 | Surface roughness | Ra≤0.5 | |

| 5 | Appearance request | Smooth surface, no dirt, water stains, watermarks, no chip, cracks, edge breakage, scratches, and other defects | |

| 6 | Clean request | After ultrasonic cleaning, clean again with alcohol, dry, and bake in time to ensure that there are no water stains and watermarks on the surface | |

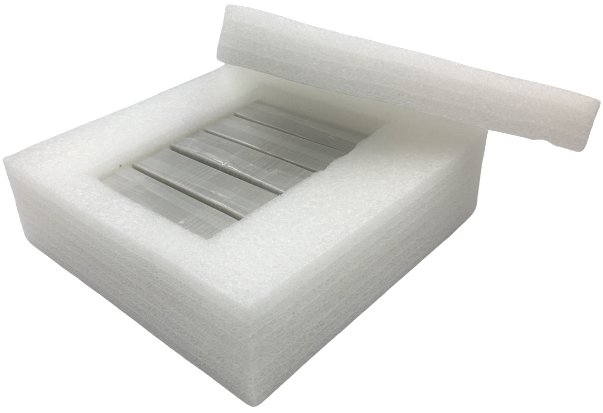

| 7 | Package request | After machining, products are placed in special pearl-cotton packaging boxes as required for turnover and transportation to avoid defects such as bruises and scratches. |

ALN Product Package requirement:

(1) The product is cleaned according to the requirements, after completely dried, placed in the special pearl cotton packaging box,

(2) One group of 100 pieces of products is placed in the small cells in the packaging box. There are 5 cells in each packaging box, and 500 pieces can be placed in total (as shown in the picture).

(3) After each version of the packaging box is filled with products, it needs to wrap the film tightly, and attach the quantity label (Picture);

(4) Put the pearl-cotton packing box into the outer carton, and paste the specification and quantity label on the surface.

(5) Package carton size: 21*21*12cm

(6) Gross weight: 1.5kgs

TO-3P-220-247-254-257-258-264 Aluminum Nitride Ceramic Thermal Pads Without Hole For MOSFET Transistor IGBT Transistor Heat Sink Package

Enquiry

Enquiry