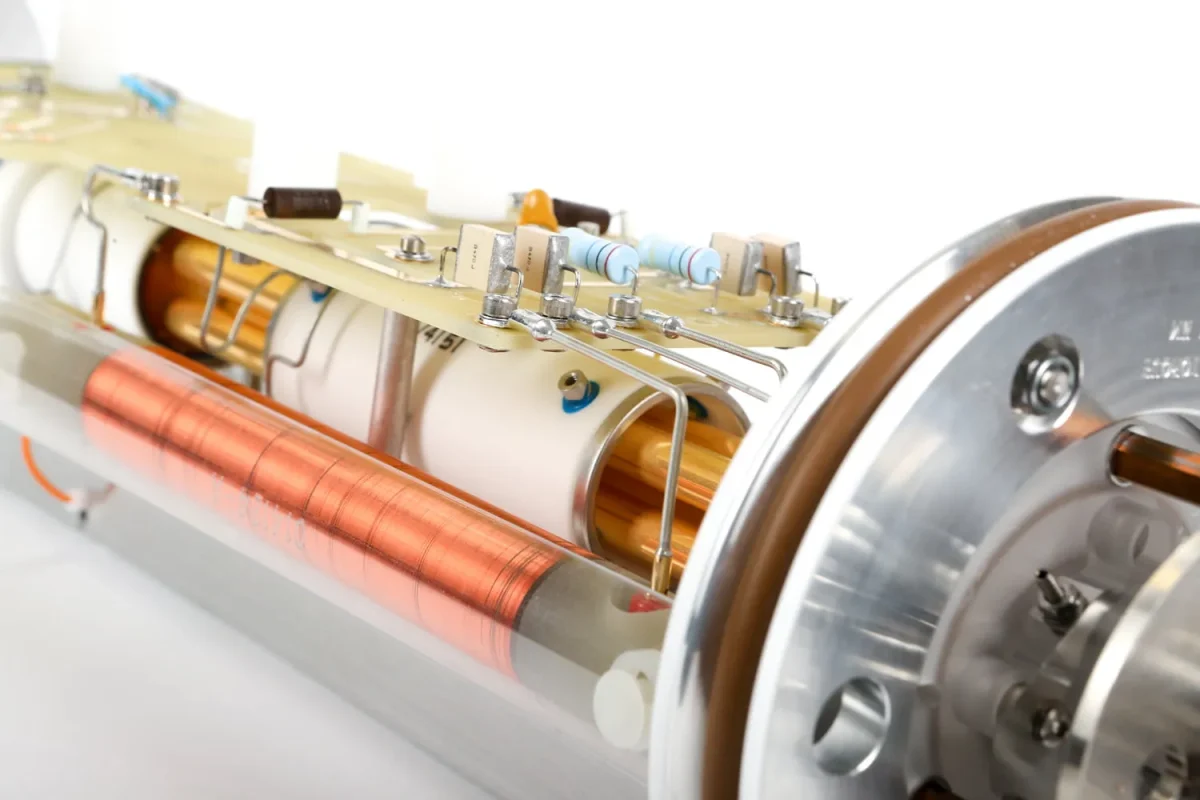

The performance of the quadrupole, one of the core components of a mass spectrometer, directly determines the resolution, sensitivity and stability of the instrument. Traditional metal quadrupoles are gradually being replaced by high-performance ceramic quadrupoles due to problems such as insufficient thermal stability and mass discrimination effect.

Material selection of ceramic quadrupoles

1.Material comparison

| Material | Al2O3 | AlN | SiC |

| Thermal conductivity | 20-30 W/mK | 170-200 W/mK | 120-200 W/mK |

| Dielectric loss | Medium | Low | Low |

| Coefficient of thermal expansion | 8.0×10⁻⁶/K | 4.5×10⁻⁶/K | 4.0×10⁻⁶/K |

2.Key material performance requirements

-High thermal conductivity: fast heat dissipation, reducing field distortion caused by thermal deformation.

-Low dielectric loss: avoid radio frequency (RF) signal attenuation.

-High dimensional stability: extremely low thermal expansion under temperature fluctuations (CTE matching metal electrodes).

Manufacturing process of ceramic quadrupole

1.Precision molding technology

-Isostatic pressing: ensure uniform density of the blank (critical for rods with aspect ratio > 20:1).

-CNC milling: diamond tool processing of high-precision surfaces (within 5μm tolerance).

2.Surface metallization:

-Sputtering gold/platinum (thickness 0.5-1μm) to ensure electrode conductivity.

-Laser resistance trimming: Adjust the electrode shape to optimize the field distribution.

3.Quality Inspection

-Morphology detection: white light interferometer to measure surface roughness (Ra<0.1μm).

-Electrical test: dielectric constant/loss tangent value determination (tanδ<0.001 at 1MHz).

Technical advantages of ceramic quadrupoles

1.Performance improvement

-Improved resolution: Low thermal deformation of ceramics improves field stability and mass resolution can reach 0.1 amu.

-Extended life: Resistant to ion bombardment, life is 3-5 times longer than metal rods (especially suitable for ICP-MS).

2. Applications

-Gas chromatography-mass spectrometry (GC-MS): AlN quadrupoles reduce thermal drift and are suitable for long-term analysis.

-Portable mass spectrometer: Lightweight ceramics (40% lighter than stainless steel) help miniaturize equipment.

Ceramic quadrupole is gradually replacing metal quadrupole because of its high thermal stability, low dielectric loss and long life, and has become the standard of high-end mass spectrometers.

Innovacera specializes in the production of ceramic components for quadrupole mass spectrometry, including ceramic filament holders, ceramic orifice plates, ceramic heaters, etc. If you have any inquiry, please kindly contact us.

Enquiry

Enquiry