The detection method of zirconium dioxide oxygen sensor is as follows:

01 Decoder detection

The abnormal operation of the oxygen sensor will store the fault code in the ECU. Therefore, through a dedicated decoder or a general decoder, the fault code 00525 of the oxygen sensor can be found-there is no signal from the oxygen sensor G39, G130, or the oxygen sensor G39, G130 is short-circuited to the positive electrode, and the oxygen can also be judged by reading the data stream. If the oxygen sensor reading stays at a constant value or changes slowly for a long time, it means that the oxygen sensor is faulty.

02 Detect the resistance of the heating element

At room temperature, it can be tested with a multimeter. When testing, unplug the oxygen sensor harness plug and test the resistance between terminals T4C/1 and T4C/2 on the plug. The resistance should be 1~5Ω at room temperature. If the resistance value is ∞ at normal temperature, it means that the heating element is open and the oxygen sensor should be replaced.

03 Detect the power supply voltage of the heating element of the oxygen sensor.

The voltage of the heating element of the oxygen sensor is the battery voltage. When the ignition switch is turned on and the contact of the fuel pump relay is turned on, the power of the heating element is turned on. When detecting the voltage of the heating element, unplug the oxygen sensor, start the engine, and detect the voltage between the terminals T4C/1 and T4C/2 on the connector socket. The voltage value should not be lower than 11V. If the voltage value is zero, it means that the fuse S5 (10A) is open or the contact of the fuel pump relay is not in good contact, and it can be repaired separately.

04 Detect the signal voltage of the sensor

When the operating temperature of the oxygen sensor is lower than 300°C, the oxygen sensor does not reach the normal operating temperature and there is no signal output. Therefore, the output voltage of the zirconium dioxide oxygen sensor should be measured when it is in the working state of 300°C or higher. The specific method to check the zirconium dioxide oxygen sensor with the auto multimeter pressure measurement method: run the engine speed at 2500r/min for about the 90s, connect the plug to the socket, and connect the digital multimeter to the oxygen sensor terminals T4C/3 and T4C/4 The signal voltage should be 0.7~1.0V when the engine is supplied with rich air (accelerator pedal is suddenly stepped on); when the engine is supplied with lean air (unplug the vacuum tube between the airflow sensor and the engine), the signal The voltage should be 0.1~0.3V; otherwise, the oxygen sensor is damaged and should be replaced.

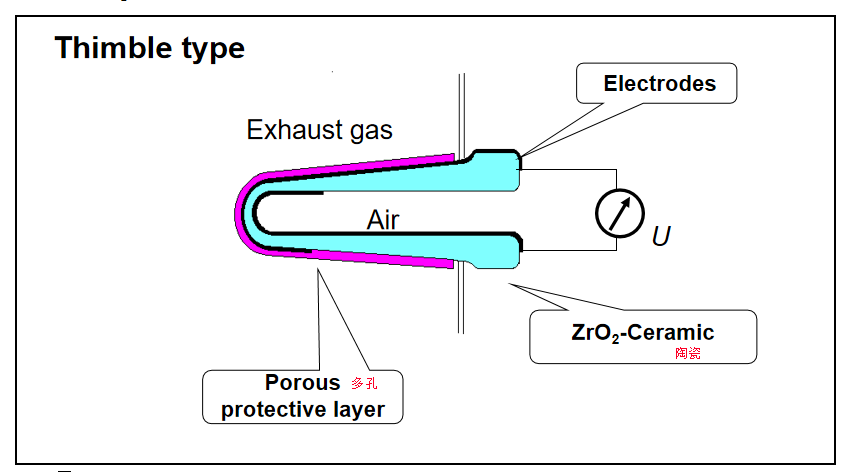

How To Detect The Abnormal Operation Of Zirconium Dioxide Oxygen Sensor-thimble oxygen sensor

How To Detect The Abnormal Operation Of Zirconium Dioxide Oxygen Sensor-thimble oxygen sensor

05 Detect the signal change frequency of the oxygen sensor

A light-emitting diode and a 300Ω resistor can be connected in series between the wires connected to the T4C/3 and T4C/4 terminals of the sensor for detection. The anode of the diode is connected to the 3# terminal, and the cathode of the diode is connected to the 4# terminal of the connector via a 300Ω resistor. When the engine is idling or running at part load, the LED should flash. The flashing frequency should not be less than 10 times per minute. If the diode does not flash or the flashing frequency is too low, it means that the oxygen sensor is damaged and the sensor should be replaced.

06 Oscilloscope detection

Using an oscilloscope to detect the signal waveform output by the oxygen sensor can intuitively determine whether the oxygen sensor is good. Test method: start the engine and warm up the sensor to over 300℃. When the engine is in closed-loop operation, connect the probe to the signal terminals T4C/2 and T4C/3 of the sensor connector, and the engine will increase its speed from idling. Observe the output signal waveform of the oxygen sensor and compare it with the standard waveform to judge the quality of the sensor.

Enquiry

Enquiry