Hermetic Micro Rectangular Connector For Sealing Solution

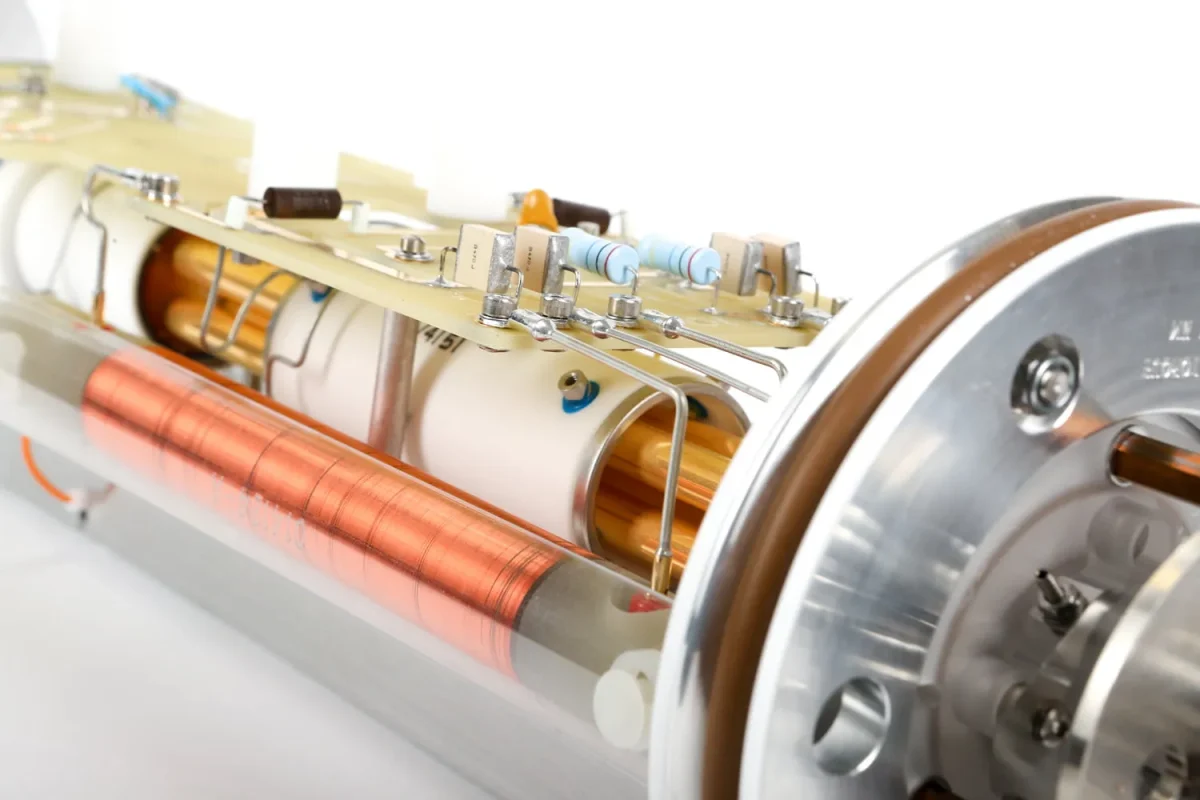

INNOVACERA hermetic micro rectangular connector utilize high-performance glass materials to achieve hermetic sealing between metal housings and electrical contacts, enabling circuit interconnections across cables in electrical/electronic systems, between cables and instrumentation devices, and with printed circuit boards (PCBs). These connectors ensure stable transmission of both low-frequency and high-frequency signals, as well as electrical currents.

Hermetic micro rectangular connector is multipin connector, featuring a glass-sintered dielectric structure with standardized 1.27mm contact spacing, the terminal interfaces accommodate wire cores with 0.1- 0.15 mm2 cross-sectional areas while supporting direct soldering to PCBS. According to engineered for environments demanding stringent hermetic sealing requirements, these micro rectangular connectors integrate miniaturized construction, lightweight design, and high-reliability contacts. Their exceptional electromagnetic shielding performance, coupled with superior vibration and impact resistance, makes them ideal for mission-critical applications such as aerospace systems, precision instruments, and other electronic systems requiring advanced hermetic protection.

Micro Rectangular Connector Contact Arrangements:

Technical advantages

Air tightness level: ≤1.0×10-9Pa·m3/s;

Insulation resistance: ≥1000MΩ;

Dielectric withstand voltage: ≥500V.

Features:

Hermetically Sealed by Sintered Glass

Contact Spacing:1.27 mm (0.05″)

Wire size:0.1-0.15 mm2

Raw options: 1-2

Contacts: 5-41

Space and weight saving.

Excellent resistance to shock and vibration.

The end can be soldered directly to PCB

If you need any hermetically sealed connectors such as micro rectangular connector, micro D connector these micro sealed connectors, welcome to contact Innovacera team at sales@innovacera.com.

Enquiry

Enquiry