Introduction: Porous ceramics are ceramic materials with fine pore structure. They are widely used in various fields due to their high porosity, high air permeability, high thermal stability and high mechanical strength. Among them, vacuum suction cups are an important application direction of porous ceramics. This article will introduce in detail the application of hole-like ceramics in vacuum suction cups, including materials, manufacturing processes, application fields, and development trends.

Porous ceramic materials include alumina and silicon carbide, which have excellent physical and chemical properties and can maintain stable performance in harsh environments such as high temperature, high pressure, and corrosion.

Porous ceramic materials have the following performance characteristics:

1. High specific surface area: porous ceramic materials have a high specific surface area, which is beneficial to adsorbing gas molecules and improving the adsorption performance of the vacuum suction cup.

2. High temperature resistance: porous ceramic materials have a high melting point and can maintain stable performance in high temperature environments.

3. Corrosion resistance: porous ceramic materials have good chemical stability and can resist erosion by various corrosive media.

4. Wear resistance: porous ceramic materials have higher hardness and better wear resistance.

Manufacturing process:

The manufacturing process of porous ceramics mainly includes the steps of mixing, shaping, drying, sintering and processing.

Molding and sintering are key steps in manufacturing porous ceramics. During the molding process, ceramic powder needs to be made into green embryos with regular shapes and sizes. During the sintering process, the blank is sintered at high temperature to form a ceramic product with a porous structure.

Application areas of porous ceramic vacuum chucks

Porous ceramic vacuum chuck are widely used in many fields due to their excellent performance, including:

1. Industrial automation: porous ceramic vacuum suction cups can replace traditional mechanical clamps in automated production lines to achieve fast and accurate material handling, such as automobile manufacturing, food processing, electronic manufacturing, etc.

2. Medical equipment: porous ceramic vacuum suction cups can be used to grab and fix surgical instruments to improve the accuracy and safety of surgical operations. and hemodialysis, etc.

3. Aerospace: porous ceramic vacuum suction cups can be used for surface cleaning and maintenance of spacecrafts, sample grabbing in space experiments, and logistics transmission of space stations, etc.

Future development of porous ceramic vacuum chucks

As the application of porous ceramic vacuum suction cups continues to expand in various fields, the future development prospects are very broad.

Regarding the future development of porous ceramic vacuum suction cups, we can discuss it from the following aspects:

1. Material optimization: further study the preparation method of new porous ceramic materials and improve the performance of the materials to meet the application needs in different fields.

2. Application expansion: Explore the application of porous ceramic vacuum suction cups in more fields, such as robotics, marine engineering, etc.

3. Intelligentization: Combined with artificial intelligence technology, it realizes intelligent control and optimization of porous ceramic vacuum suction cups and improves its work efficiency.

Categories of vacuum Chuck:

1. Thinning Chucks

2. dicing suction Chucks

3. cleaning suction Chucks

4. printing suction Chucks

5. carrying suction cups/Transportation chuck

Application machine model of vacuum chuck

1. DFG8540

2. 7AF-II

3. DAS321/DAD341

4. DAD3350

5. ADT7100

6. A-WD-100A

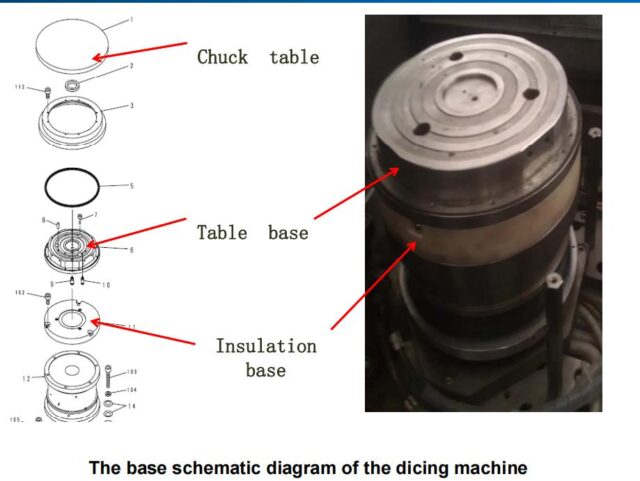

Structure of vacuum suction chucks

Enquiry

Enquiry