Ceramic Vacuum Chuck is a kind of uniform solid or vacuum body produced by using nano-powder. A large number of connected or closed ceramic materials are generated in the material through high-temperature sintering.

The material is Al2O3 or SIC, which is widely used in Semiconductors and electronic devices.

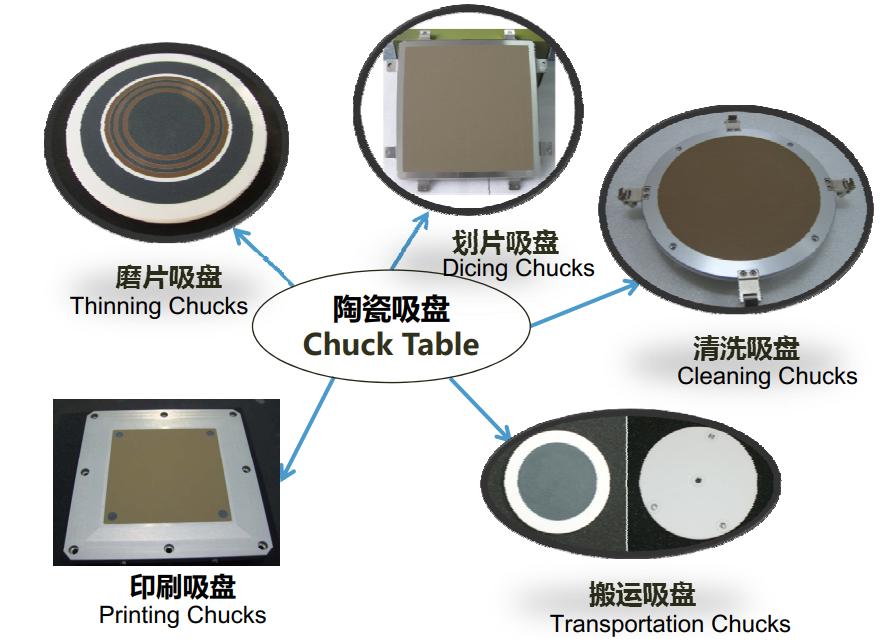

In these applications, it can fix semiconductor wafers, glass substrate materials and other working objects by Vacuum Suction.

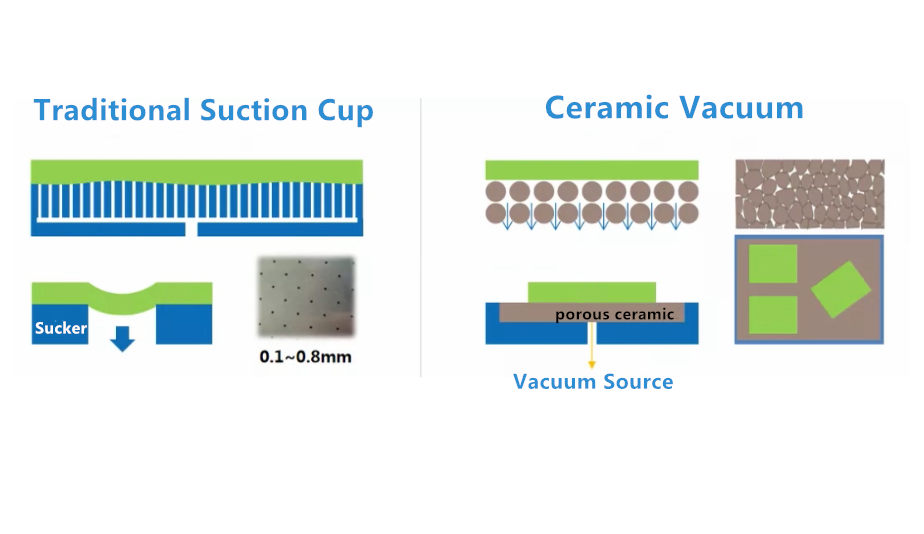

Compared with the characteristics of traditional suction cups for the single specification of workpieces, the regional suction function of Ceramic Vacuum suction cups helps to improve the smoothness of the production line and its performance, also avoid the traditional suction cups on the workpiece (especially the Thin Film material) scratches and suction marks.

In addition to being used to adsorb workpieces, Ceramic Vacuum Chucks can also be used in transmission-type air float modules. Even large pieces of glass substrates and other workpieces can be prevented from directly contacting the platform during transportation and transfer, avoiding.

Attachment of contaminants, stress, static electricity and damage to the glass substrate occurs. Moreover, the porous material can greatly reduce the gas flow, and can achieve the effect of uniform air pressure in the air cushion layer and can maintain a certain floating height.

Enquiry

Enquiry