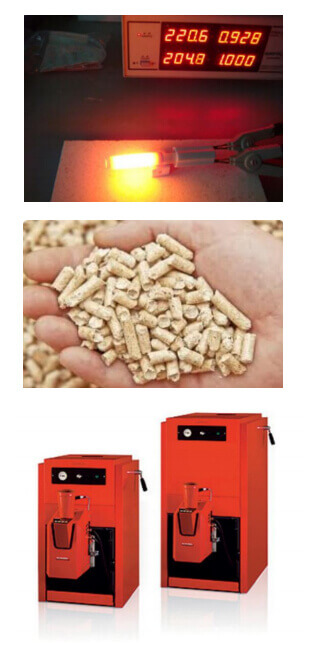

HTCC is an acronym for High-temperature co-fired ceramics; HTCC ceramic wood pellet stove is made up of high melting point metal heating material such as tungsten, molybdenum or molybdenum – manganese and 92-96% alumina ceramic substrates. The metal heating resistance slurry is printed onto the tape casting ceramic green body according to the design requirement, several layers of ceramic green body are then laminated together and is fired at 1500 ~ 1600 ℃ high temperature, with the aid of 4-8% sintering additive, to form the alumina ceramic heating element.

They are deployed in the following areas:

1. Heating applications above 750°C, in which standard heating cartridges would have long since failed.

2. Very precise, rapid heating due to the extremely low thermal mass .

3. Efficient hot gas generation through the extremely large heat transfer surface area. Our heater portfolio covers a broad performance spectrum (depending on the desired

purpose) and various patented structural forms. In addition to this the wood pellet burner can be designed on an individual customer basis and be equipped with a complete electrical connection technology.

Systems

Straw burner Other biomass burner Wood pellet burner

Wood chips burner Straw burner Other biomass burner

![]()

Further product advantages:

• Ready assembled, easy-to-install systems

• Space-saving, noiseless and impervious to overheating

(in case the blower fails)

• Extremely long-lasting and resilient

• Minimal energy consumption

• Completely electrically insulated

• No exposed electrical contacts

• No sensitive welding points

• Long lasting (non aging)

• Time to ignition 60~90 seconds

• Available in 100V / 120V / 220V / 240V AC

• Fully electrically insulated with no exposed electric contacts

• Impervious to oxidation and corrosion

• Ignite wood pellet, wood chips, split logs, straw and

other biomass

• Comply with RoHS, REACH regulation on Hazardous Subsctances

Not without reason, the high temperature heating

elements pellet igniter is the reliable standard ignition

system for pellet heating systems in Europe-hundreds

of satisfied customers speak for themselves.

Ceramic Igniters For Solid Fuel Furnaces

230V Ceramic Igniter

| Model | Voltage/ | Size | Ceramic Socket | Wire | |

| Power | Ceramic | Metal kit | |||

| INC-H1-1 | 230V 210W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | – | 300-500mm |

| INC-H1-2 | 230V 225W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | – | 300-500mm |

| INC-H1-3 | 230V 240W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | – | 300-500mm |

| INC-H1-4 | 230V 255W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | – | 300-500mm |

230V Alumina Ceramic Igniter for Stove

| Model | Voltage/ | Size | Wire | ||

| Power | Ceramic | Metal kit | |||

| INC-H2-1 | 230V 160W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | G3/8” | 300-500mm |

| INC-H2-2 | 230V 180W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | G3/8” | 300-500mm |

120V 230W Alumina Ceramic Heater for Burner

| Model | Voltage/ | Size | Ceramic Socket | Wire | |

| Power | Ceramic | Metal kit | |||

| INC-H3-1 | 120V 230W | 90*Φ10.5*φ6.5mm | OD17.5*35/OD24*45/OD25*35 | G3/8” | 300-500mm |

230V 300W 350W Pellet Igniter for Biomass Burner

| Model | Voltage/ | Size | Ceramic Socket | Wire | |

| Power | Ceramic | Metal kit | |||

| INC-H4-1 | 230V 350W | 108*Φ11.5*φ6.5mm | OD17.5*35 | – | 300-500mm |

| INC-H4-2 | 230V 300W | 108*Φ11.5*φ6.5mm | OD17.5*35 | – | 300-500mm |

150W 170W 230W High Temperature Ceramic Heater

| Model | Voltage | Size | Ceramic Socket | Wire | |

| /Power | Ceramic | Remark | |||

| INC-H5-1 | 230V 150W | 70*Φ10.5*φ6.5mm | OD6.5*35 | Pluggability | 300-500mm |

| INC-H5-2 | 230V 170W | 70*Φ10.5*φ6.5mm | OD6.5*35 | Pluggability | 300-500mm |

| INC-H5-3 | 230V 230W | 70*Φ84-133*φ6.5mm | OD6.5*35 | Pluggability | 300-500mm |

| INC-H5-4 | 230V 150W | 70*Φ10.5*φ6.5mm | OD6.5*35 | Pluggability | 300-500mm |

Alumina Ceramic Heater

Enquiry

Enquiry