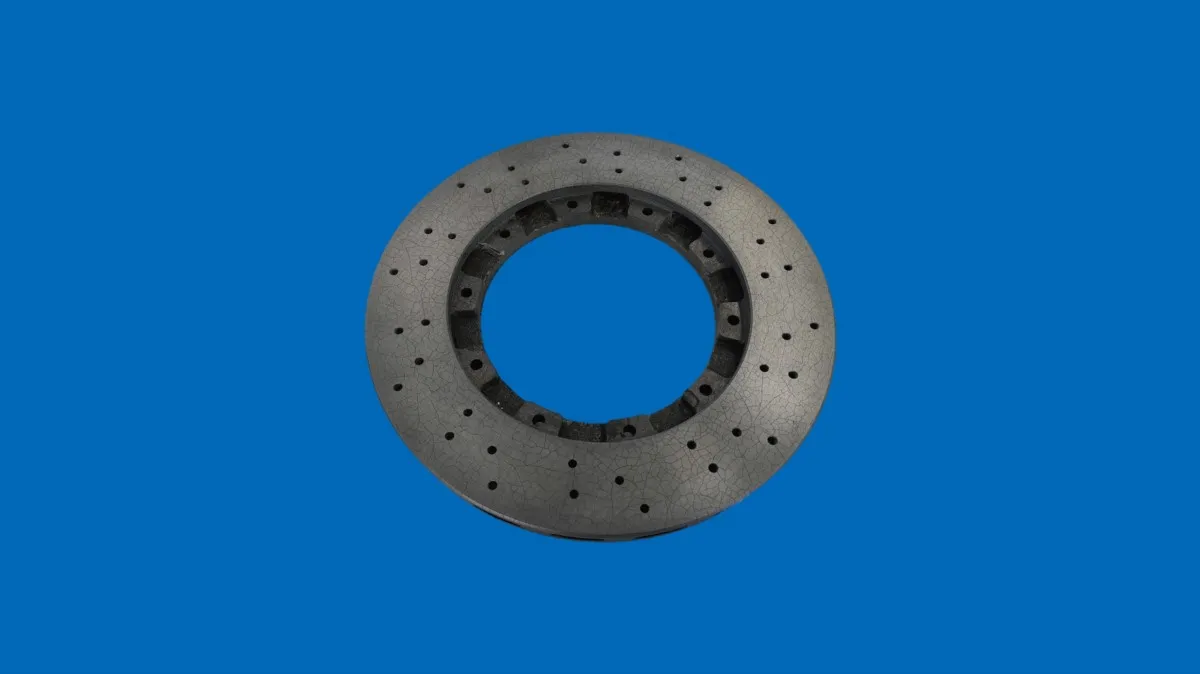

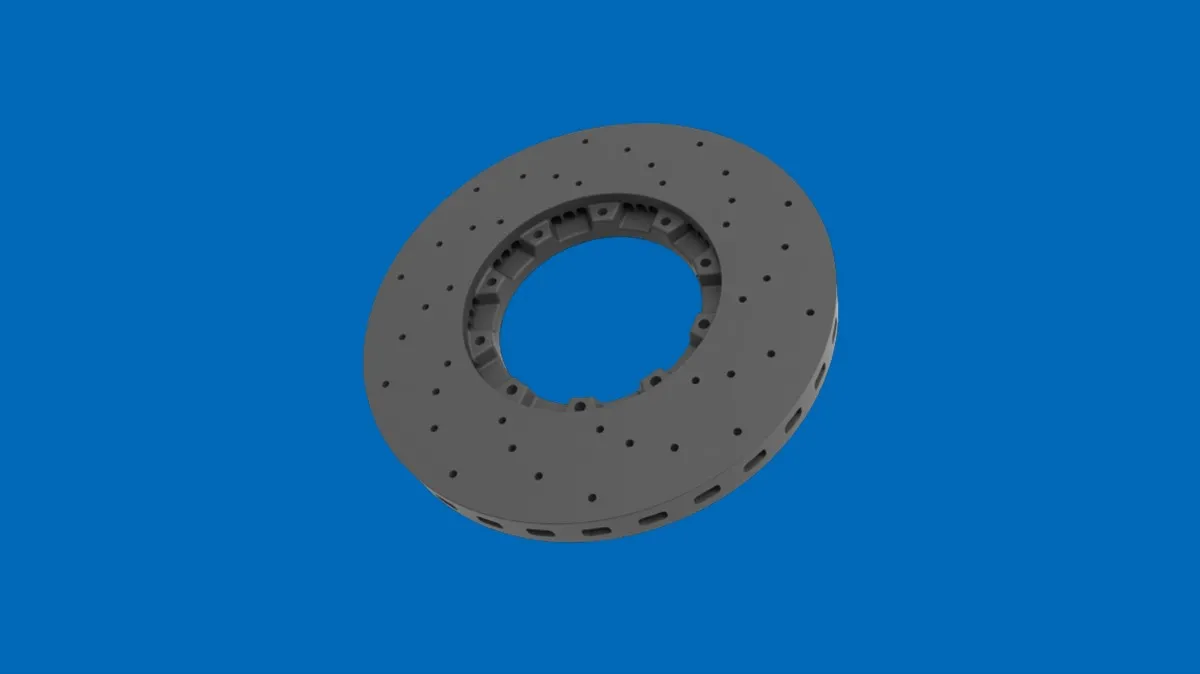

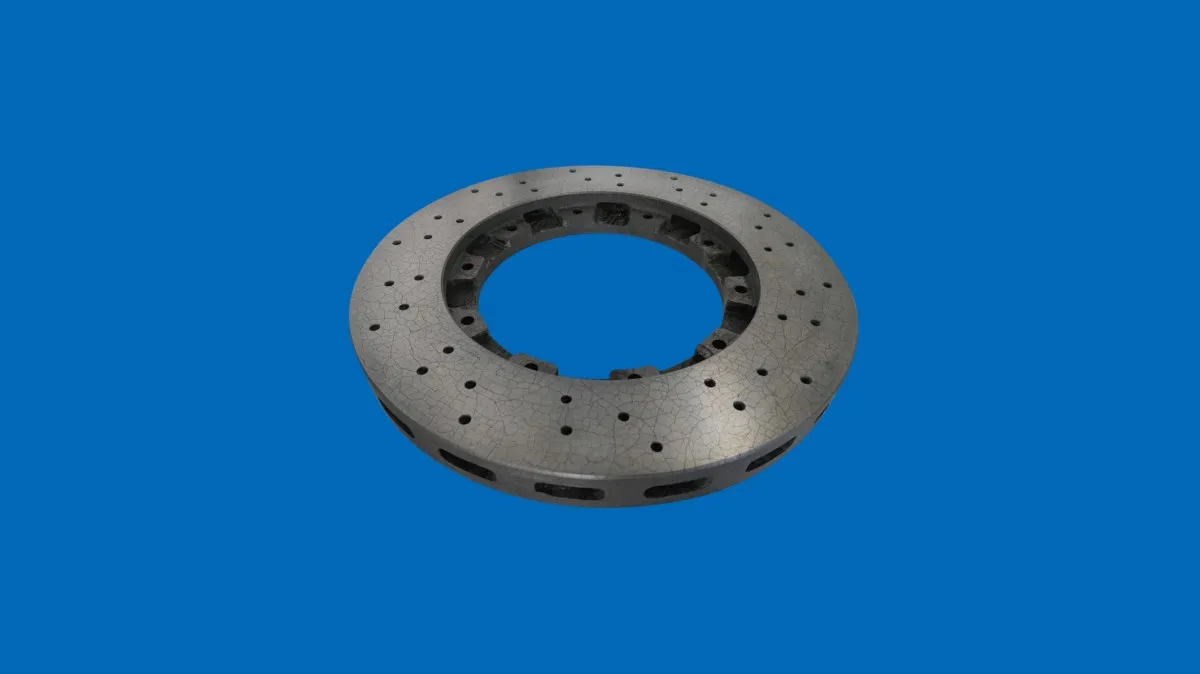

Product Description

Carbon Ceramic Brake Discs are designed to deliver consistent braking force under severe operating conditions. Compared with traditional cast iron brake discs, carbon ceramic materials offer significantly reduced weight, superior heat resistance, and a much longer service life.

The carbon–ceramic composite structure ensures excellent resistance to thermal shock and deformation, even under repeated high-energy braking. These properties help maintain stable friction coefficients, reduce brake fade, and improve overall vehicle control and safety.

Key Features

Excellent high-temperature resistance with stable braking performance

Low density and lightweight design for reduced unsprung mass

Outstanding wear resistance and long service life

High thermal conductivity for efficient heat dissipation

Strong resistance to thermal shock and oxidation

Suitable for extreme braking conditions and high-speed operation

Applications

Carbon Ceramic Brake Discs are widely used in demanding braking systems, including:

High-performance sports cars

Supercars and luxury performance vehicles

Motorsport and racing vehicles

Track-day and performance-modified vehicles

Advanced braking systems requiring lightweight and high thermal stability

Material Advantages

Carbon ceramic composites combine the strength of carbon fibers with the thermal and chemical stability of ceramic matrices. This structure enables the brake discs to maintain mechanical integrity at elevated temperatures while minimizing thermal expansion and material fatigue, ensuring reliable braking performance over long-term use.

Overview

| Product | Diameter ‘a’ (mm) | Thickness ‘b’ (mm) | Width ‘c’ (mm) | P.C.D ‘e’ (mm) | Diameter ‘d’ (mm) | Thickness ‘f’ (mm) | Diameter ‘g’ (mm) | Diameter ‘h’ (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 350X32D65 | 350 | 32 | 65 | 9 | 200 | 18 | 220 | 180 | 3.82 |

| 355X28D54 | 355 | 28 | 54 | 9 | 227 | 18 | 247 | 207 | 3.15 |

| 355X32D54 | 355 | 32 | 54 | 9 | 227 | 18 | 247 | 207 | 3.44 |

| 355X32D62 | 355 | 32 | 62 | 9 | 211 | 18 | 231 | 191 | 3.78 |

| 355X32D67 | 355 | 32 | 67 | 9 | 201 | 18 | 221 | 181 | 3.97 |

| 360X26D55 | 360 | 26 | 55 | 9 | 230 | 18 | 250 | 210 | 2.98 |

| 360X26D69 | 360 | 26 | 69 | 9 | 202 | 18 | 222 | 182 | 3.45 |

| 360X32D64 | 360 | 32 | 64 | 9 | 212 | 18 | 232 | 192 | 3.92 |

| 370X24D68 | 370 | 24 | 68 | 9 | 214 | 17 | 234 | 194 | 3.30 |

| 370X30D72 | 370 | 30 | 72 | 9 | 206 | 18 | 226 | 186 | 4.22 |

| 378X36D56 | 378 | 36 | 56 | 9 | 246 | 23 | 266 | 226 | 4.41 |

| 380X28D54 | 380 | 28 | 54 | 9 | 252 | 18 | 272 | 232 | 3.40 |

| 380X28D57 | 380 | 28 | 57 | 9 | 246 | 18 | 266 | 226 | 3.53 |

| 380X28D61 | 380 | 28 | 61 | 9 | 238 | 18 | 258 | 218 | 0 |

| 380X28D68 | 380 | 28 | 68 | 9 | 224 | 18 | 244 | 204 | 0 |

| 380X30D60 | 380 | 30 | 60 | 9 | 240 | 18 | 260 | 220 | 3.87 |

| 380X32D56 | 380 | 32 | 56 | 9 | 248 | 18 | 268 | 228 | 3.83 |

| 380X34D64 | 380 | 34 | 64 | 9 | 232 | 23 | 252 | 212 | 0 |

| 380X34D72 | 380 | 34 | 72 | 9 | 216 | 23 | 236 | 196 | 4.93 |

| 380X34D80 | 380 | 34 | 80 | 9 | 202 | 23 | 220 | 180 | 0 |

| 380X36D72 | 380 | 36 | 72 | 9 | 216 | 23 | 236 | 196 | 5.24 |

| 380X36D80 | 380 | 36 | 80 | 9 | 200 | 23 | 220 | 180 | 0 |

| 390X32D68 | 390 | 32 | 68 | 9 | 234 | 18 | 254 | 214 | 4.51 |

| 390X36D72 | 390 | 36 | 72 | 9 | 226 | 23 | 246 | 206 | 5.43 |

| 393X36D88 | 393 | 36 | 88 | 9 | 197 | 23 | 217 | 177 | 6.21 |

| 400X28D58 | 400 | 28 | 58 | 9 | 264 | 18 | 284 | 244 | 3.79 |

| 400X36D72 | 400 | 36 | 72 | 9 | 236 | 23 | 256 | 216 | 5.59 |

| 400X36D90 | 400 | 36 | 90 | 9 | 200 | 23 | 220 | 180 | 6.45 |

| 405X34D62 | 405 | 34 | 62 | 9 | 261 | 23 | 281 | 241 | 4.84 |

| 405X34D72 | 405 | 34 | 72 | 9 | 241 | 23 | 261 | 221 | 5.34 |

| 410X32D68 | 410 | 32 | 68 | 9 | 254 | 18 | 274 | 234 | 4.80 |

| 410X36D72 | 410 | 36 | 72 | 9 | 246 | 23 | 266 | 226 | 5.77 |

| 410X36D78 | 410 | 36 | 78 | 9 | 237 | 23 | 252 | 212 | 6.11 |

| 420X40D101 | 420 | 40 | 101 | 9 | 198 | 23 | 218 | 178 | 8.09 |

| 440X40D101 | 440 | 40 | 101 | 9 | 218 | 23 | 238 | 198 | 8.62 |

Enquiry

Enquiry