A New Generation of Pellet Grill Igniter-Silicon Nitride Quartz Igniter

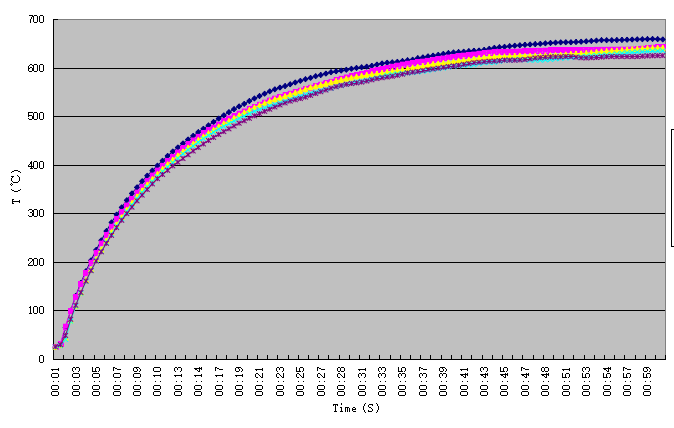

Silicon nitride ignition technology is a new technology commonly used in ignition devices. As new arrival of ceramic igniter also called Quartz Crystal Igniter is a very good solution in the pellet ignition market. Compared with traditional ceramic lighters, the ignition time is reduced to less than 60 seconds. It is based on the special properties of silicon nitride materials under high temperature and high pressure environments, and can provide high-energy and high-reliability ignition capabilities.It can speed up your cooking process and minimize the white smoke period before ignition.

Today, let’s take a look about the silicon nitride igniter.

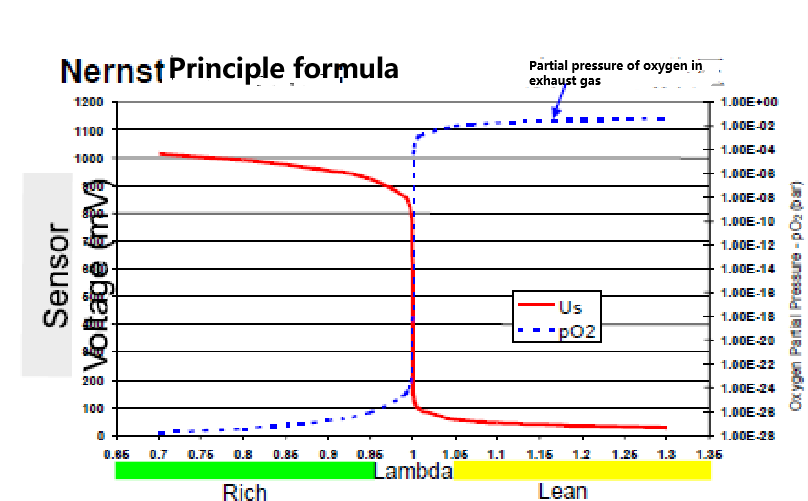

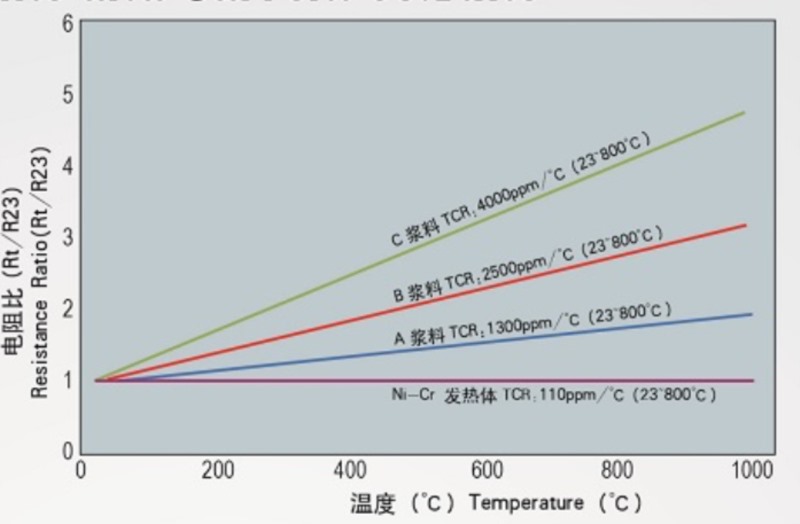

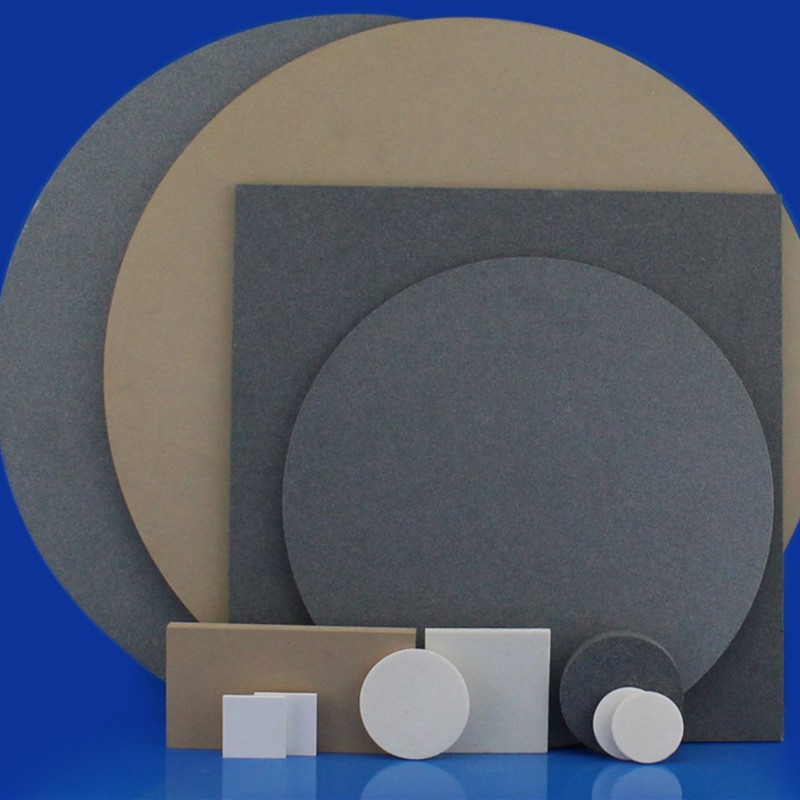

Silicon nitride ceramics have the characteristics of high strength and high temperature resistance. It has the best comprehensive mechanical properties among ceramic materials, and has good thermal shock resistance, oxidation resistance, wear resistance and corrosion resistance. It is the third ceramic used in thermal engine parts. A candidate material. In traditional fields, silicon nitride ceramics are used as bearing balls, rollers, ball races, tools and molds, new ceramic cutting tools, pump plungers, spindle sealing materials, etc.

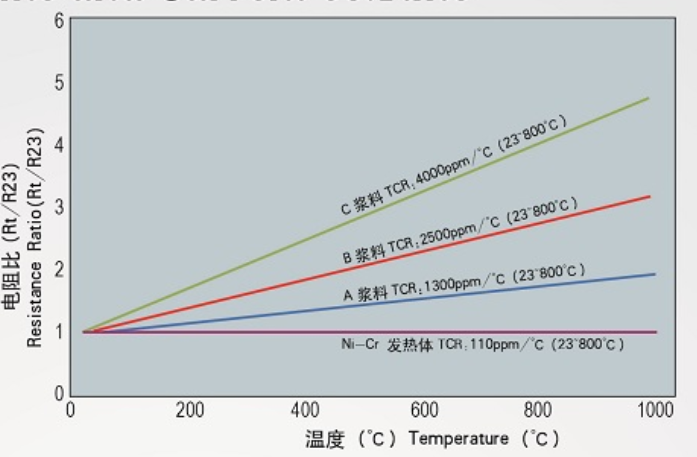

With the improvement of the preparation process, the thermal conductivity and dielectric properties of silicon nitride have been significantly improved. It can be used in electric heating, thermal conductive substrates and other fields. Used as a water heater heating element, its high thermal conductivity enables it to quickly transfer heat to the heated medium, and its good thermomechanical properties and insulation properties ensure its safety. Can be widely used in various types of instant heating, water storage and thermostats. It can also be used as an industrial heating source and a heating and insulation device for special liquids.

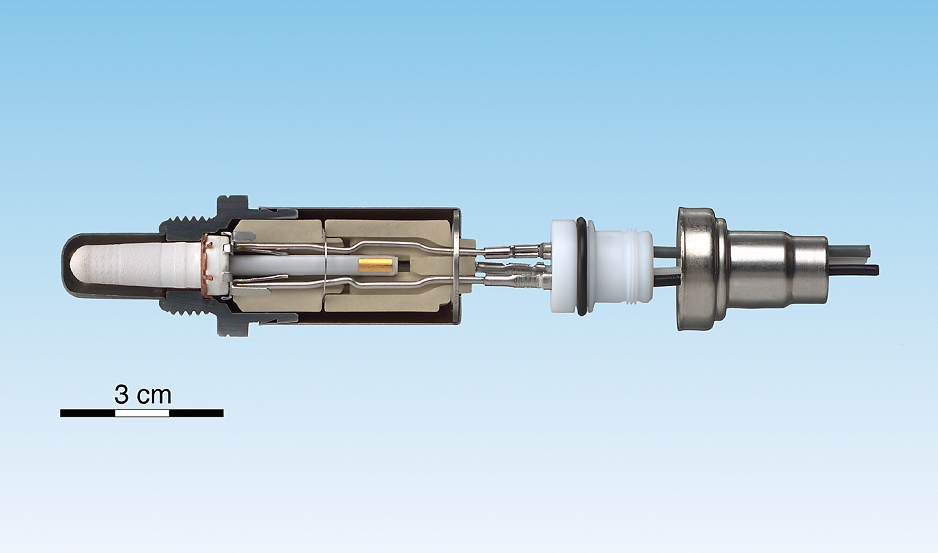

![]()

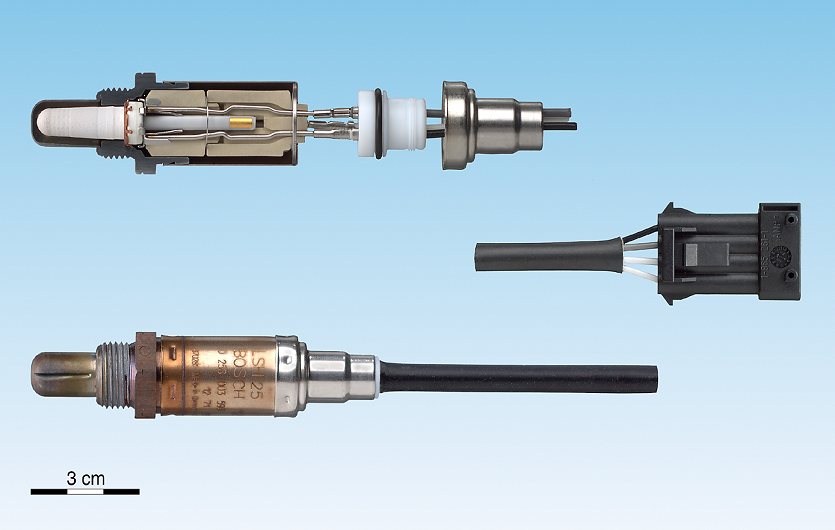

Product Introduction:

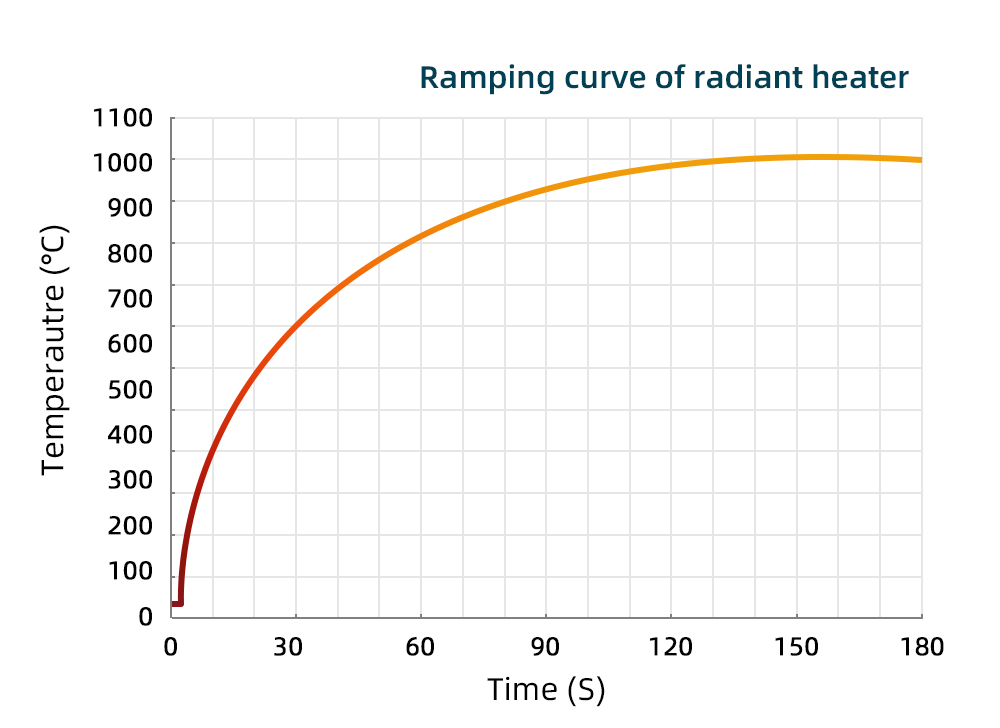

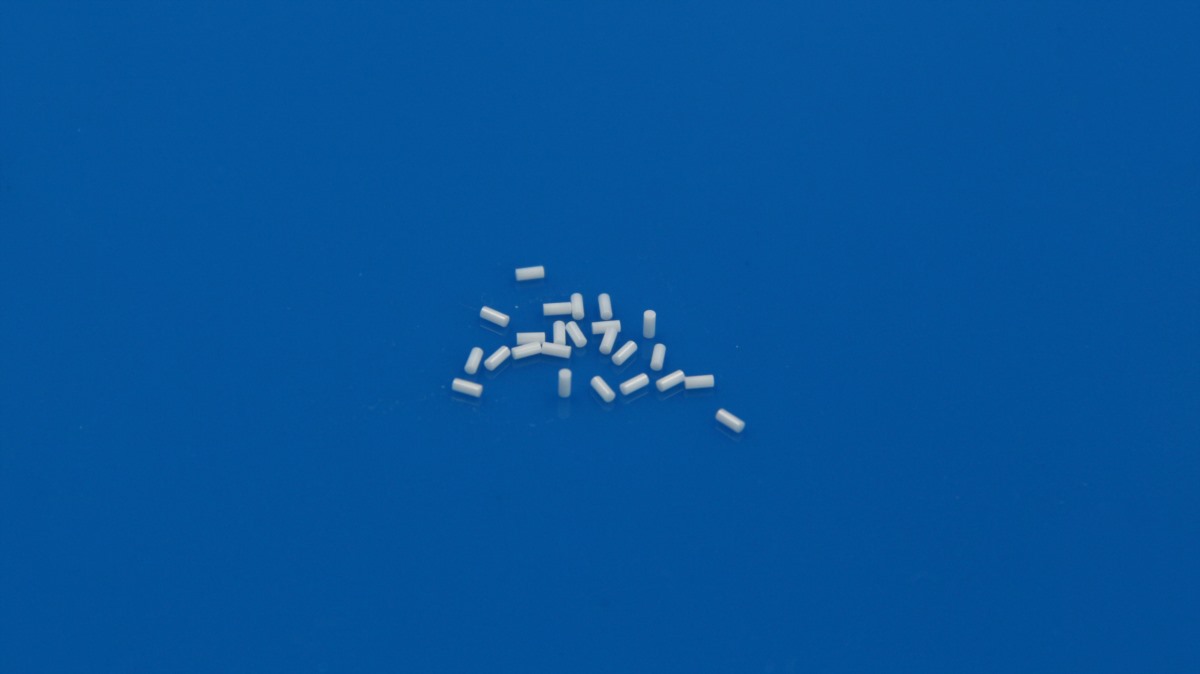

Silicon nitride ceramic igniter can heat up to 800~1000℃ in tens of seconds and ignite fuel by direct heat transfer or blast heat transfer. A temperature buffer area is set on the ignition rod to protect the terminal from damage. The insulation package at the wire joint can effectively prevent short circuits caused by conductive ash. With reasonable installation methods and ignition procedures, silicon nitride ceramic ignition rods can be used safely for several years.

Specification:

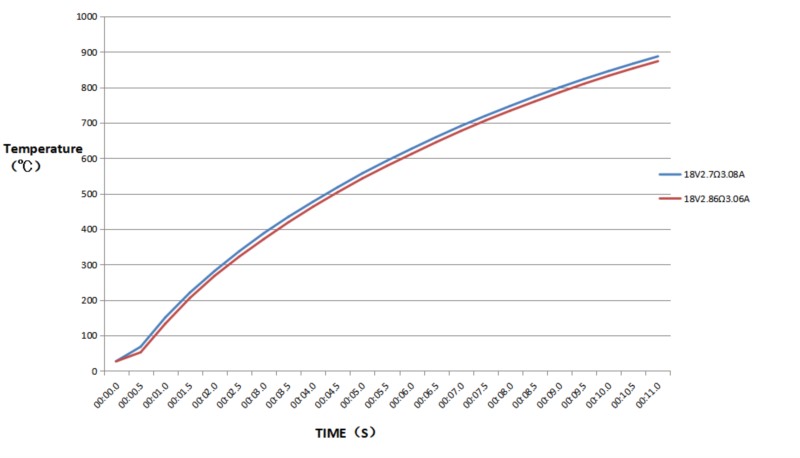

| Rapid heating | Heating faster. up to 1000°c in 30 seconds |

| Range of temperature | 1100~1200 °C |

| mall size / High watt density | High-watt density discharge allow high thermak efficiency |

| High insulation | |

| Direct water and kerosene heating | |

| Vacuum environment | |

| Oxidation and chemical resistance | |

|

provides the best quality silicon nitride Igniter, ceramic igniter for biomass pellet stove, and BBQ grill applications.

|

|

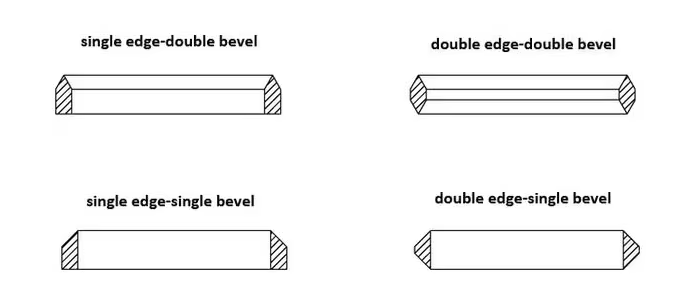

| Model | Material | Voltage/ Power |

Size | Ceramic Socket | Wire | |

| Ceramic | Metal kit | |||||

| INC-H6 | Silicon Nitride | 230V 300W | 90*10.8*3.9mm | OD17.5*32 | – | 300-500mm

Length and type can be customized |

Advantages of Silicon Nitride Igniter:

– When it contact with the ash or the pipe holder, it does not create a short circuit.

– Quartz Crystal igniters are 2 times more resistant to mechanical shocks than ceramic lighters.

– High resistance to burning pellets.

-The black quartz crystal igniter (candle, lighter) reaches over 1000 ° in 10 seconds, also called quartz igniter is the new generation for burning pellets and other biomass boilers.

-Maintenance is even simpler.

Application:

1. Ignition of biomass boilers, ignition of straw incinerators

2. Ignition of gas and oil (such as natural gas)

3. Treatment of automobile exhaust and industrial waste gas

4. Gas heating (air, working gas)

5. Fireworks generator

6. Brazing equipment

7. Corrosive environment heater

8. Laboratory special heating elements, heating system customization

9. Mold and tool heating

10. Barbecue charcoal igniter

![]()

Precautions when using 300W Black Quartz Crystal Ignition for Biomass Boiler

-This product is for industrial use only.

-Use a variable transformer to perform voltage control or use a temperature controller to implement temperature control.

-Use the heater under atmospheric pressure in the air.

-Do not apply excessive external forces (tension, bending, etc.) to the lead wire joint.

-Since the heater material is silicon nitride (ceramics), please handle carefully, as it may crack if you drop it or hit it.

-Please fix the insulator part for attaching the heater. Also, please be careful as overtightening may cause damage.

Our advantage

1. Factory/manufacturer

2. More than 150 to 200 online employees

3. Welcome to customize

4. Monthly output of heater igniter: 550,000

5. Fast delivery time for existing models: 1-3 days

Embrace the cutting-edge rapid igniters, capable of starting a fire in your pellet grills in just 90 seconds. Welcome to contact with us for more information.

Enquiry

Enquiry