Ceramic Packages For Semiconductor Discrete Device Power Electronics

Innovacera develops ceramic packages and metal packaging shells to meet customer customized requirements. Innovacera’s factory has established robust capabilities in the research and development of ceramic and glass materials, tape casting for green ceramics, microwave/RF simulation, packaging technologies including the ceramic packaging shells/substrates, brazing/sealing, and surface treatment processes, offering customers comprehensive and integrated packaging solutions.

![]()

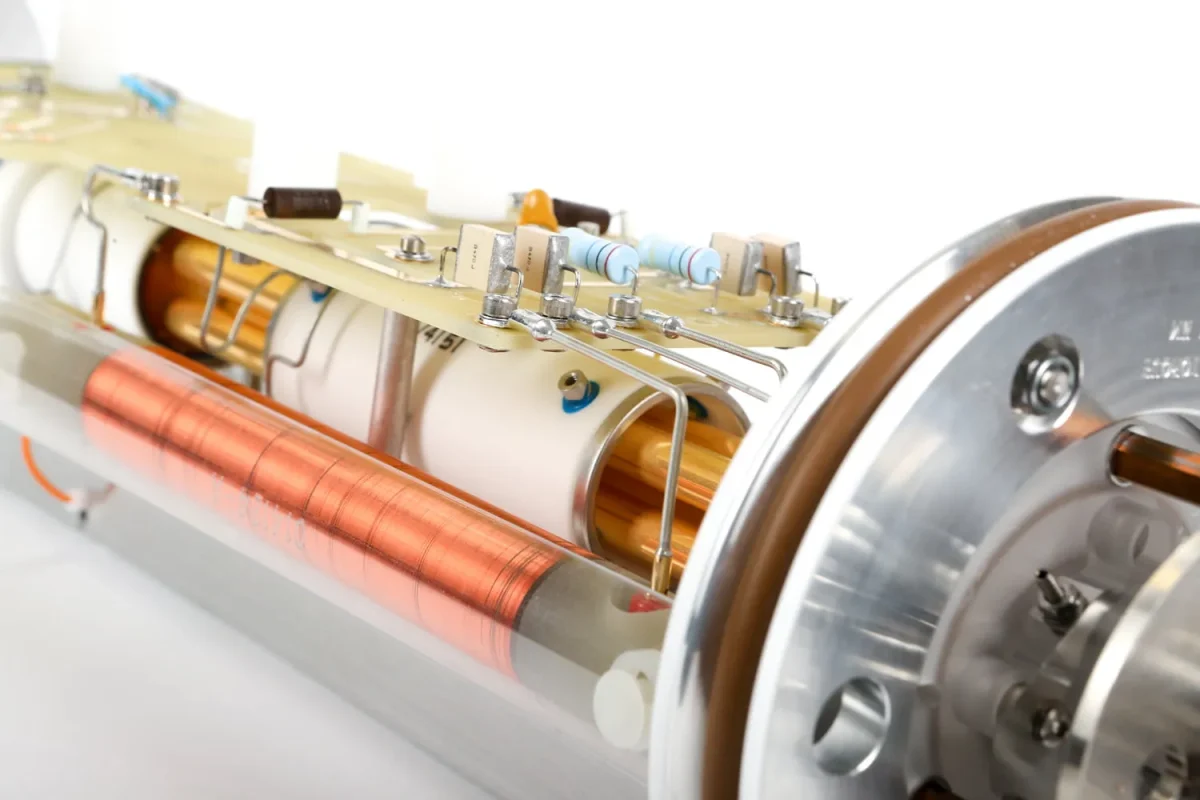

Innovacera offers ceramic packages for semiconductor discrete device power electronics by using ceramic-to-metal sealing technologies. Ceramic packages adopt a ceramic sidewall structure instead of the traditional bead-type insulated ceramic design, significantly improving the voltage withstand performance of the housing. Copper-cored kovar lead pins and WCu heat sinks are bonded onto multilayer alumina ceramic packages or aluminium nitride ceramic packages. It is primarily used for encapsulating high-power transistors, diodes, triodes, and power modules.

Ceramic Packages Current Carrying Capacity:

| Typical TO-Style Package | ||

| Package Model | TO-254 | TO-257 |

| Plating Structure | Ni+Au | Ni+Au |

| Heat Sink Material | WCu | WCu |

| Ceramic Size (mm) | 9.6×9.6 | 7.5×6.0 |

| Lead Diameter | Lead Material | Max. Current Capacity |

| 1.0mm | Copper-cored Kovar | 20A max |

| 0.8mm | Copper-cored Kovar | 15A max |

| 1.0mm | Copper | 60A max |

| 0.8mm | Copper | 45A max |

Ceramic Packages Features:

Heat Sink Materials: WCu, CPC, CMC, etc.

Lead Materials: Copper-cored Kovar, copper.

Insulation Resistance: 1010Ω(500V)

Withstand Voltage: > 1000V.

Leak Rate: ≤1×10³Pa ·cm³/s

Plating Options: Full nickel plating, full Ni/Au plating.

Sealing Method: Parallel seam welding.

Temperature Cycling: -65℃~+175℃, 500 cycles.

If you have interesting about power electronics and semiconductor discrete device ceramic packages, welcome to contact Innovacera sales team at sales@innovacera.com.

Enquiry

Enquiry