Zirconium Beads and Mill Jars: Essential Tools for Precision Grinding

In industries that require precision milling and grinding, Zirconium Beads and Mill Jars are highly valued for their durability, efficiency, and consistent performance. These components, made from Zirconia (ZrO2), play a crucial role in material processing, particularly in industries such as pharmaceuticals, ceramics, and chemical engineering.

What Are Zirconium Beads and Mill Jars?

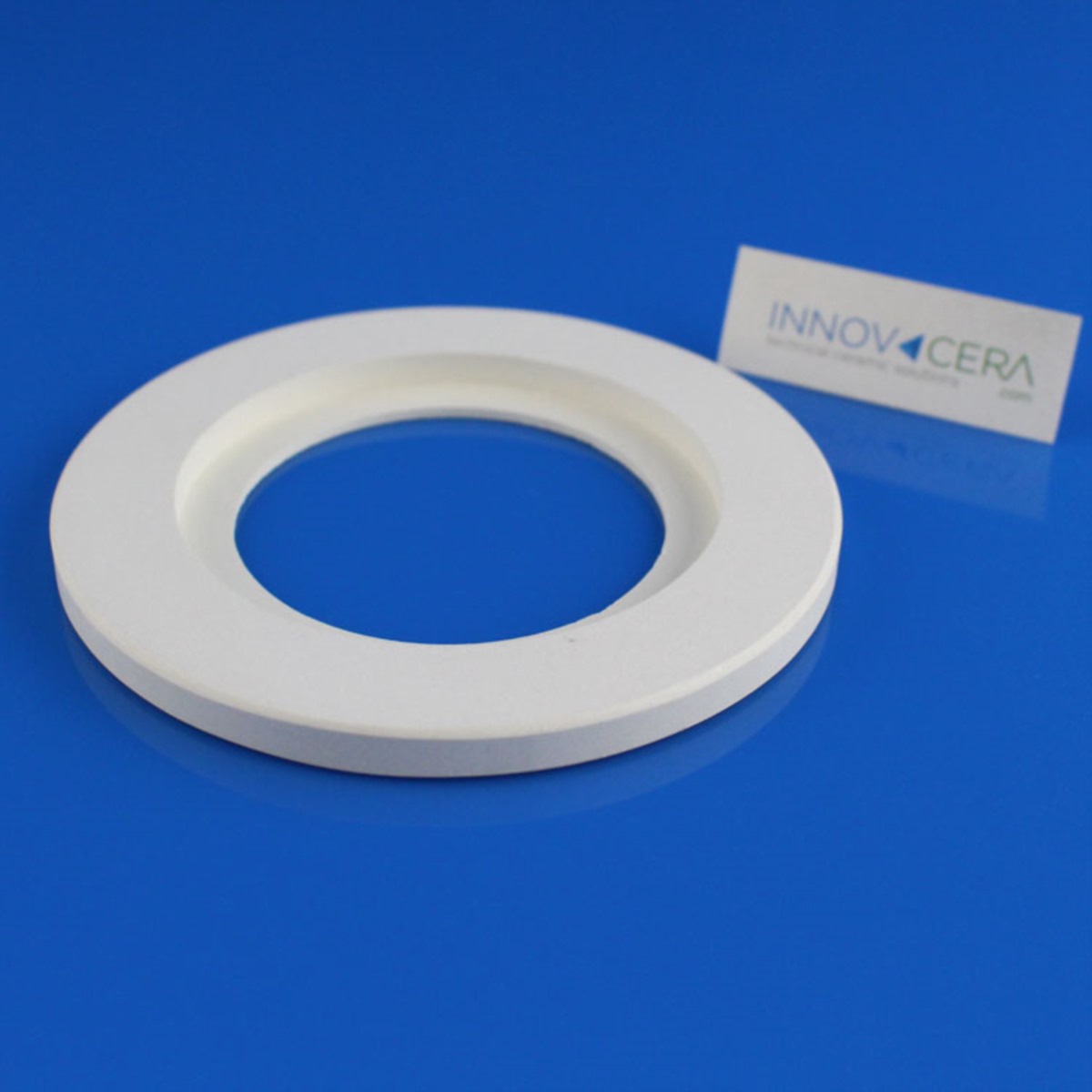

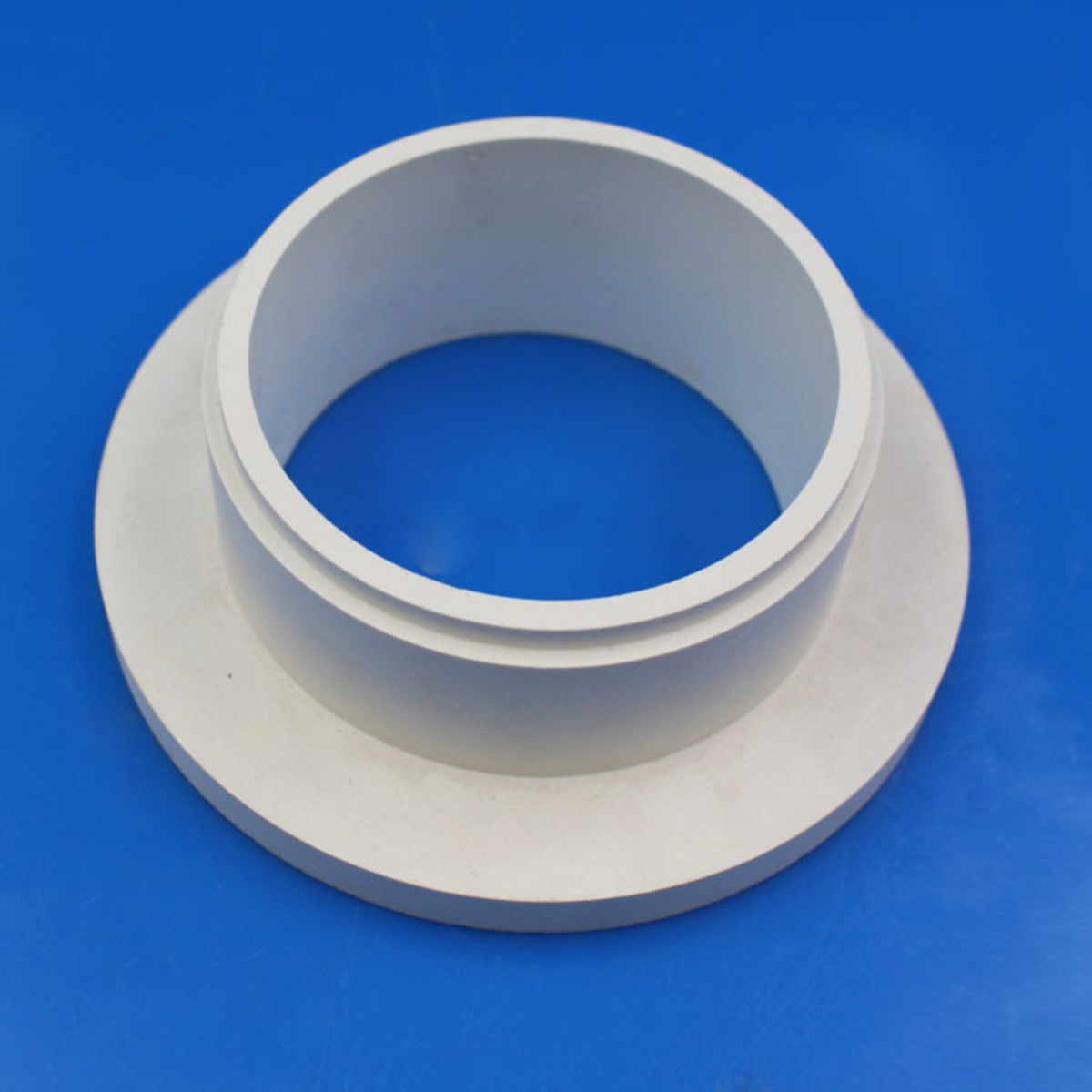

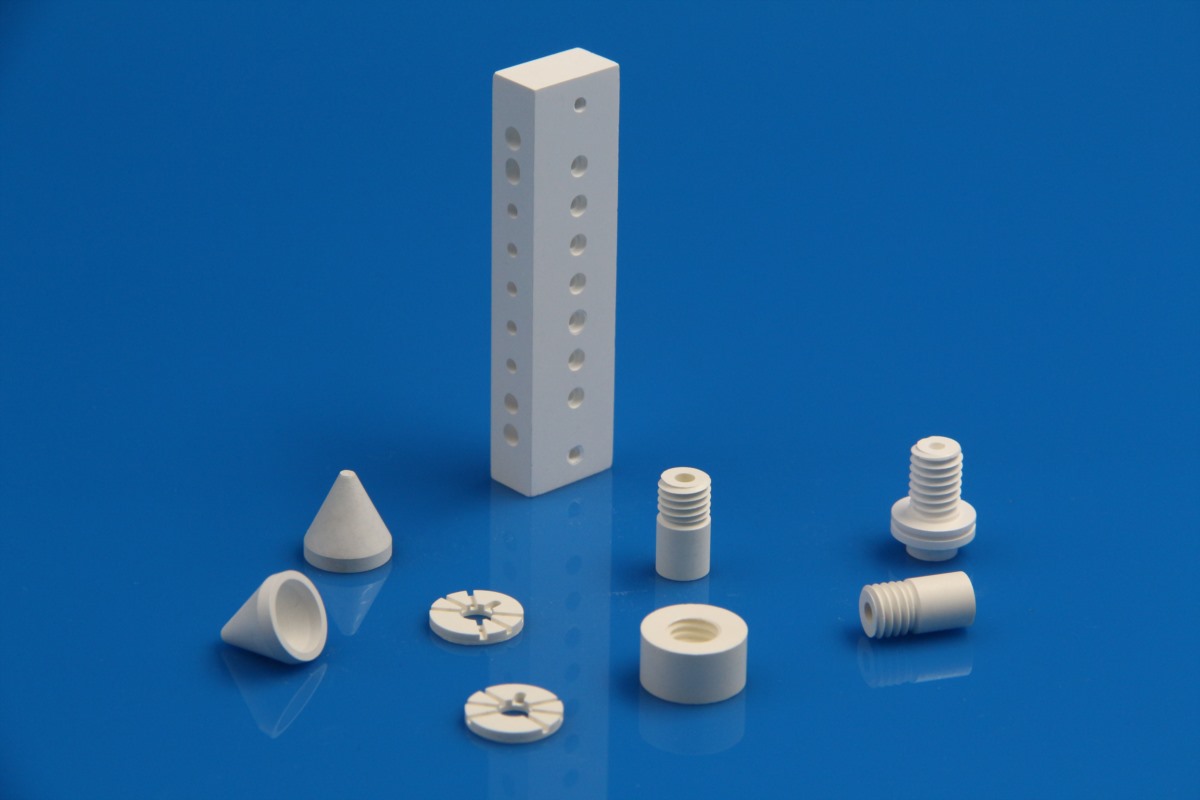

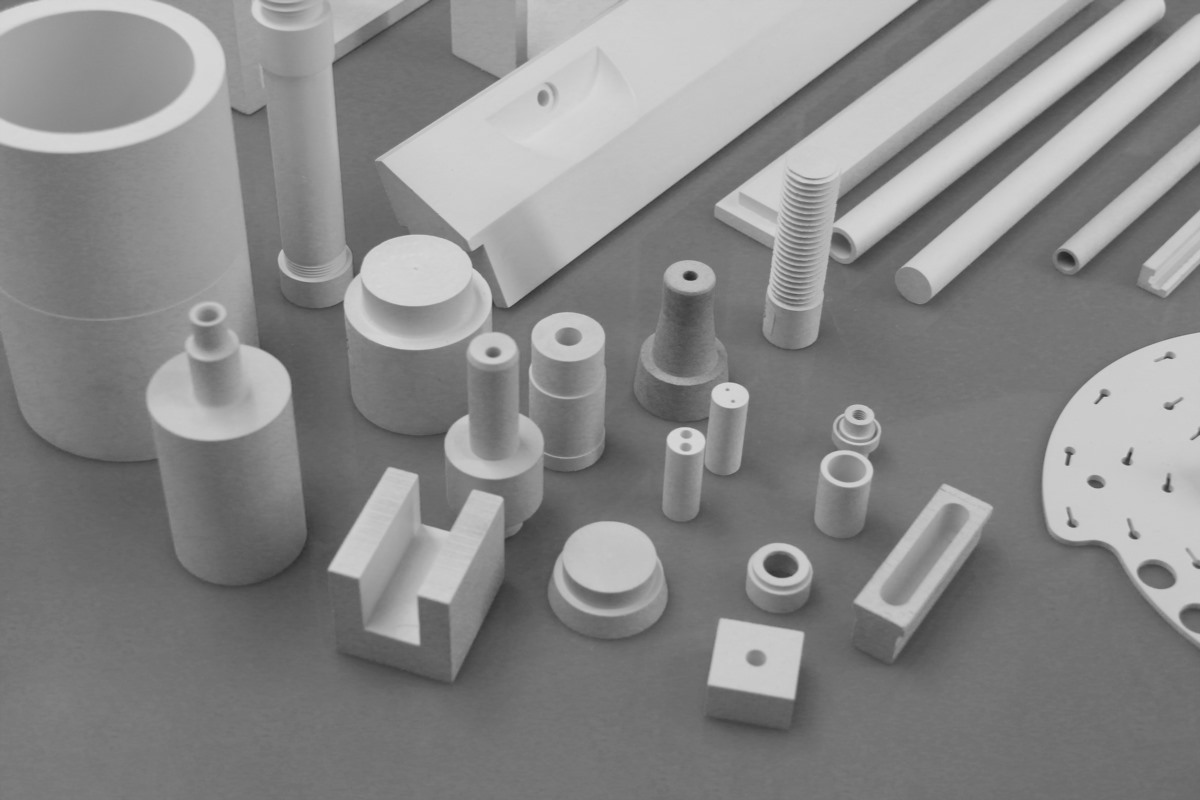

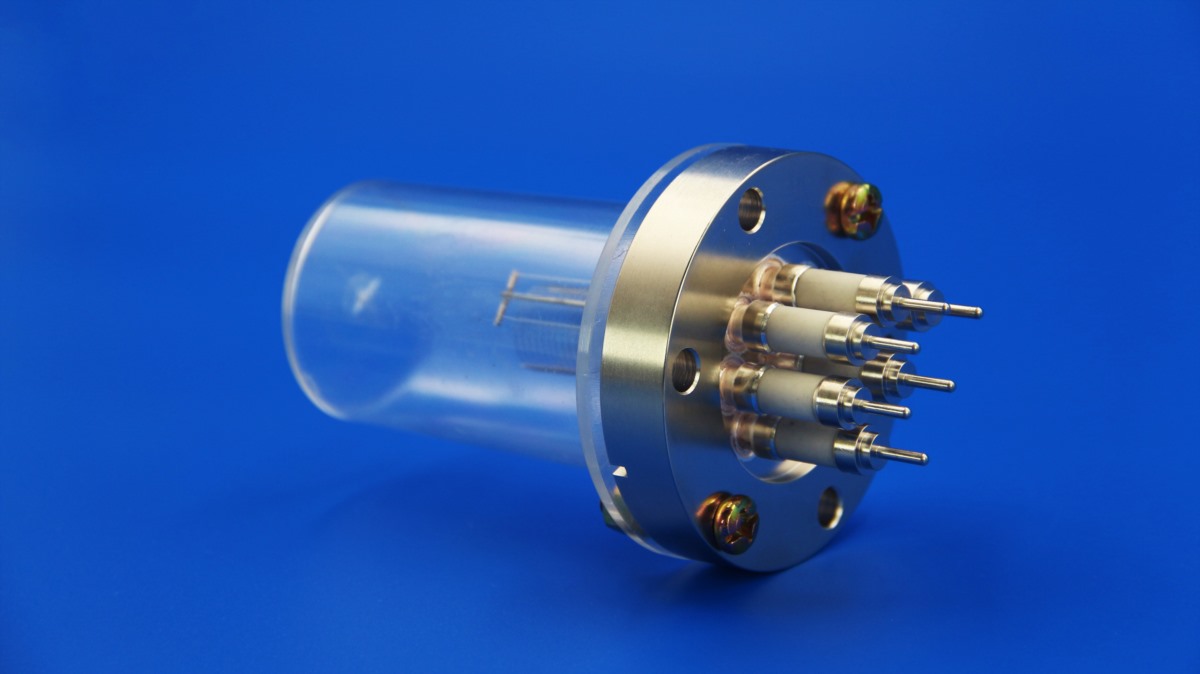

Zirconium Beads are spherical grinding media commonly used in milling and grinding operations. Their dense structure and high resistance to wear make them ideal for grinding tough materials into fine powders. Mill Jars, typically made of Zirconia, are containers used to house the materials being ground, providing a durable and inert environment that ensures efficient and contamination-free processing.

Key Features of Zirconium Beads and Mill Jars

High Density: Zirconium Beads have a high density compared to other types of grinding media. This allows for faster grinding, improved efficiency, and better particle size reduction during milling processes.

Wear Resistance: Both Zirconium Beads and Mill Jars are known for their exceptional wear resistance. This characteristic ensures a longer lifespan, even under continuous use in high-friction environments.

Chemical Stability: Zirconia (ZrO2) is chemically inert, meaning it does not react with the materials being ground. This property is especially important in industries where purity is critical, such as pharmaceuticals and fine chemicals.

Smooth Surface: The smooth surface of Zirconium Beads minimizes abrasion and reduces contamination of the milled product, ensuring high-quality results.

High Strength and Toughness: Zirconium Beads and Mill Jars can withstand extreme mechanical stresses, making them ideal for high-intensity milling applications.

Applications of Zirconium Beads and Mill Jars

Zirconium Beads and Mill Jars are used across various industries for different purposes:

Pharmaceutical Industry: In the production of medications, fine milling is essential to achieve precise particle sizes for proper dosage and solubility. Zirconium Beads and Mill Jars ensure contamination-free grinding.

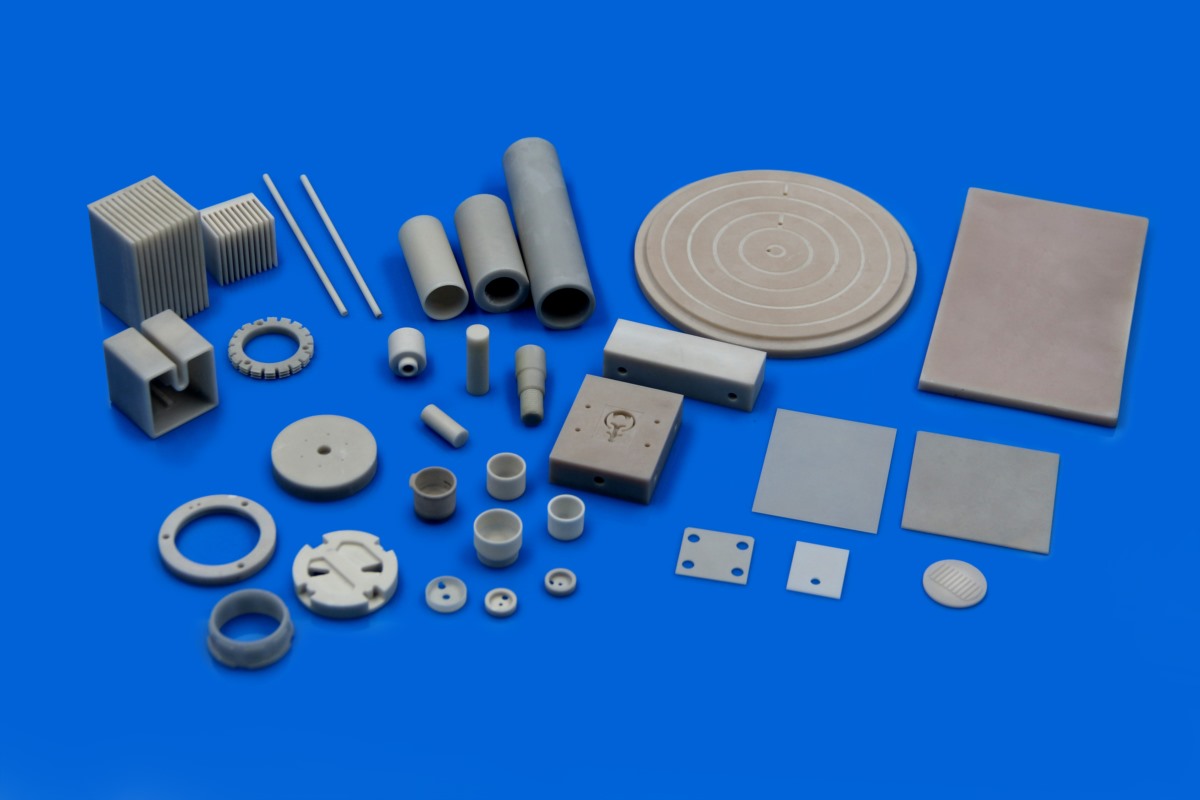

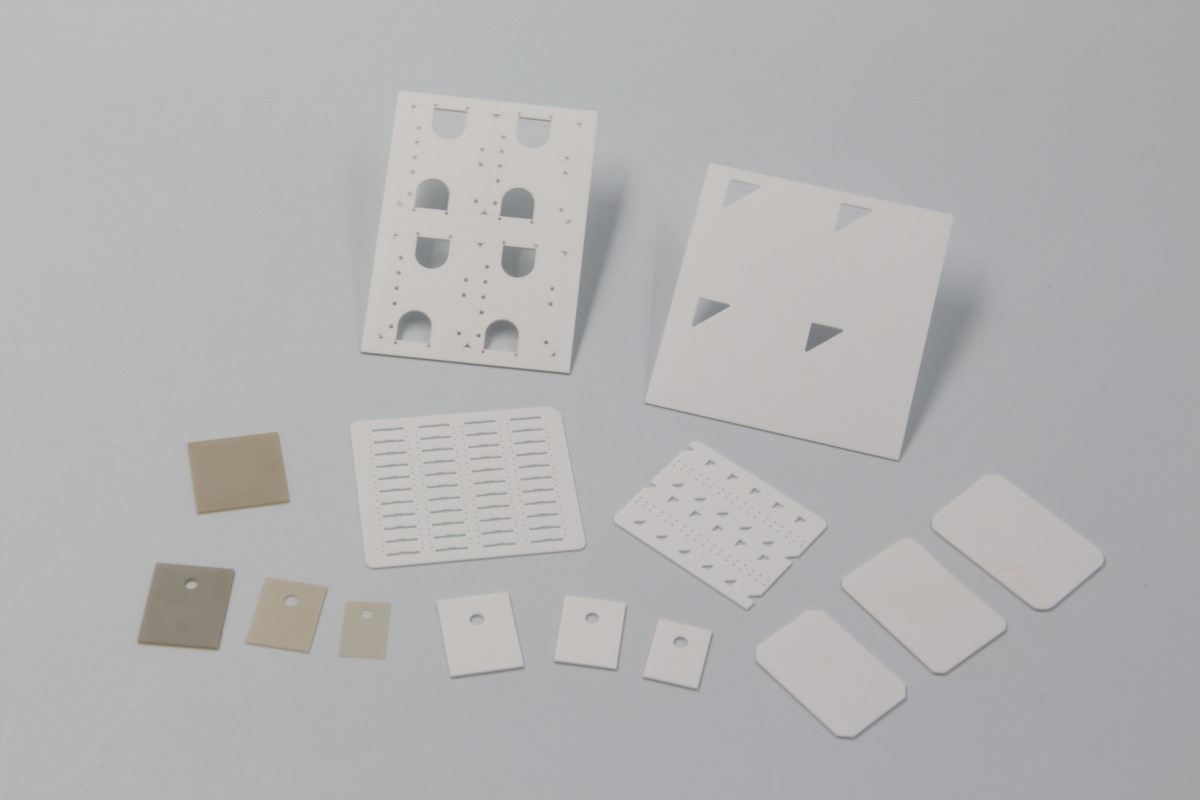

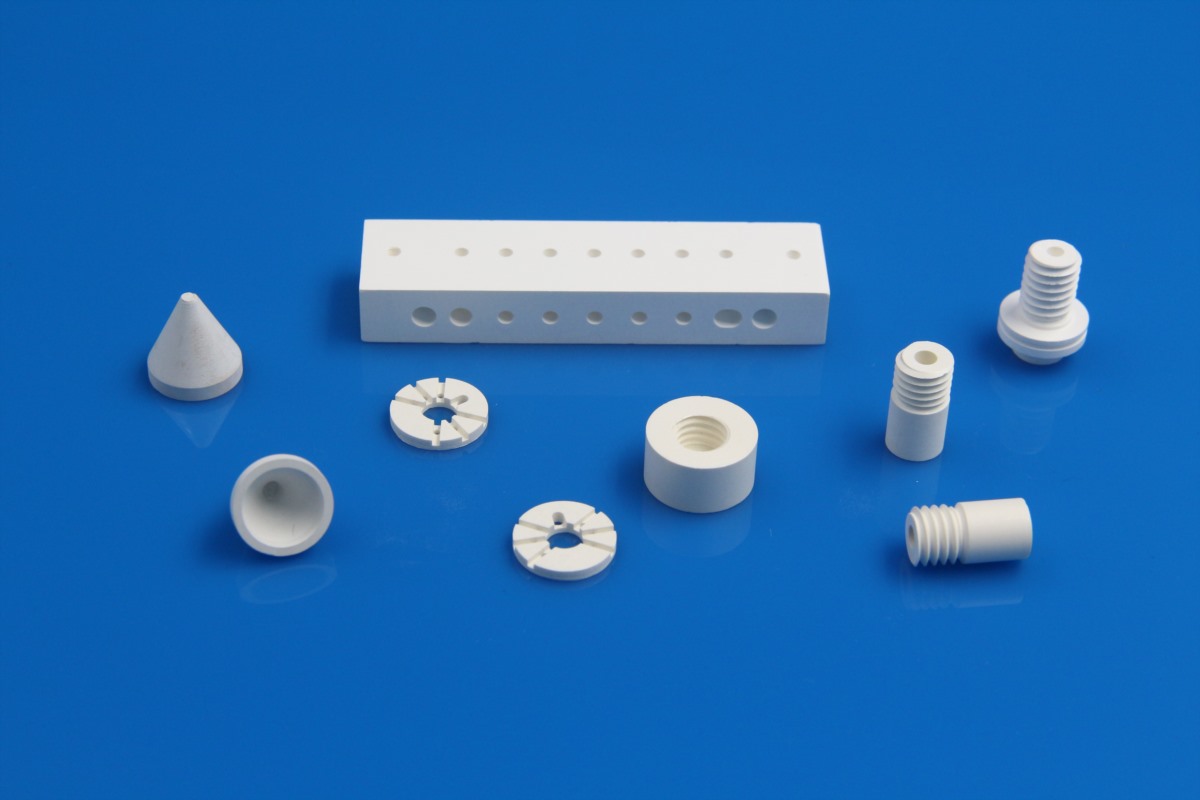

Ceramic Industry: These tools are vital in the ceramic industry for grinding raw materials into fine powders, which are then used to create ceramic products with improved strength and durability.

Paints and Coatings: In the production of high-quality paints and coatings, Zirconium Beads ensure that pigments are ground evenly, resulting in uniform color and consistency.

Nanomaterials: For researchers working with nanotechnology, Zirconium Beads are essential for achieving ultra-fine particle sizes, critical for the development of advanced materials.

Zirconium Beads and Mill Jars are indispensable in industries where precise milling, durability, and chemical stability are essential. Their Zirconia (ZrO2) composition offers high density, wear resistance, and chemical inertness, making them ideal for various grinding applications. By incorporating Zirconium Beads and Mill Jars into your milling process, you ensure efficient, high-quality results with minimal contamination.These tools are the perfect choice for industries seeking reliable and efficient grinding solutions.

Enquiry

Enquiry