Aluminum Nitride Wafer Substrates: The Foundation for Semiconductors Manufacturing

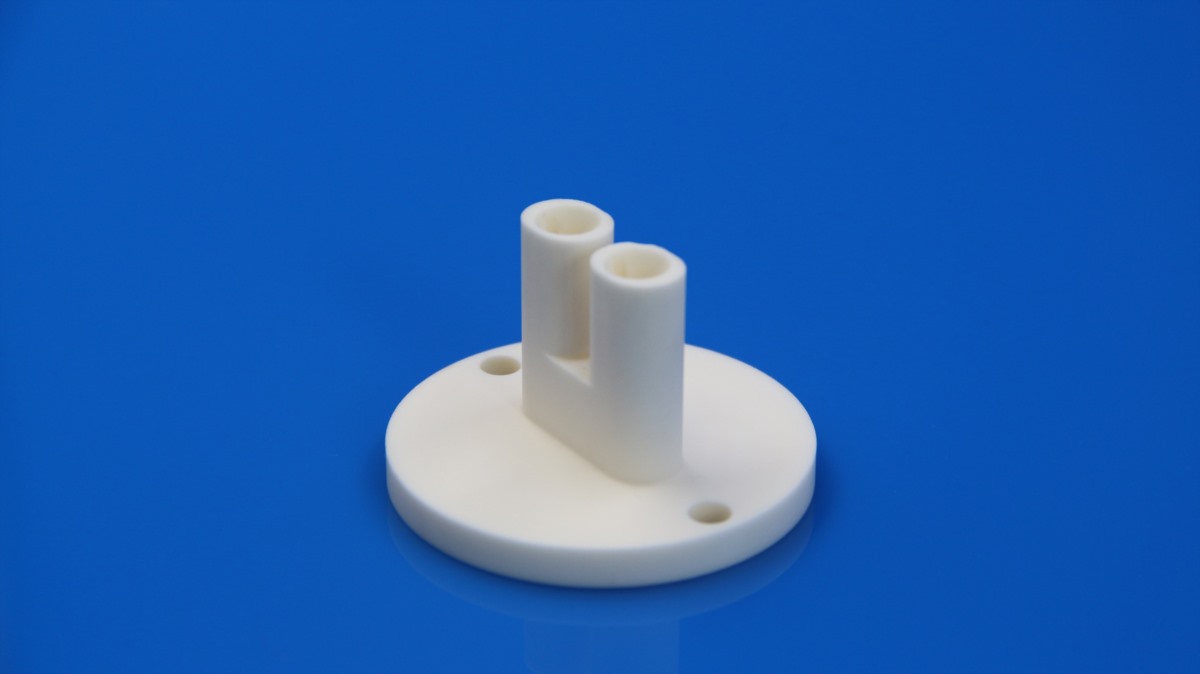

Aluminum Nitride Wafer Substrates are a crucial component in the semiconductor industry, known for their exceptional thermal and electrical properties. Aluminum Nitride (AIN) materials have gained prominence due to their compatibility with silicon, making them ideal for a variety of wafer-related applications.

The Importance of Aluminum Nitride Wafer Substrates

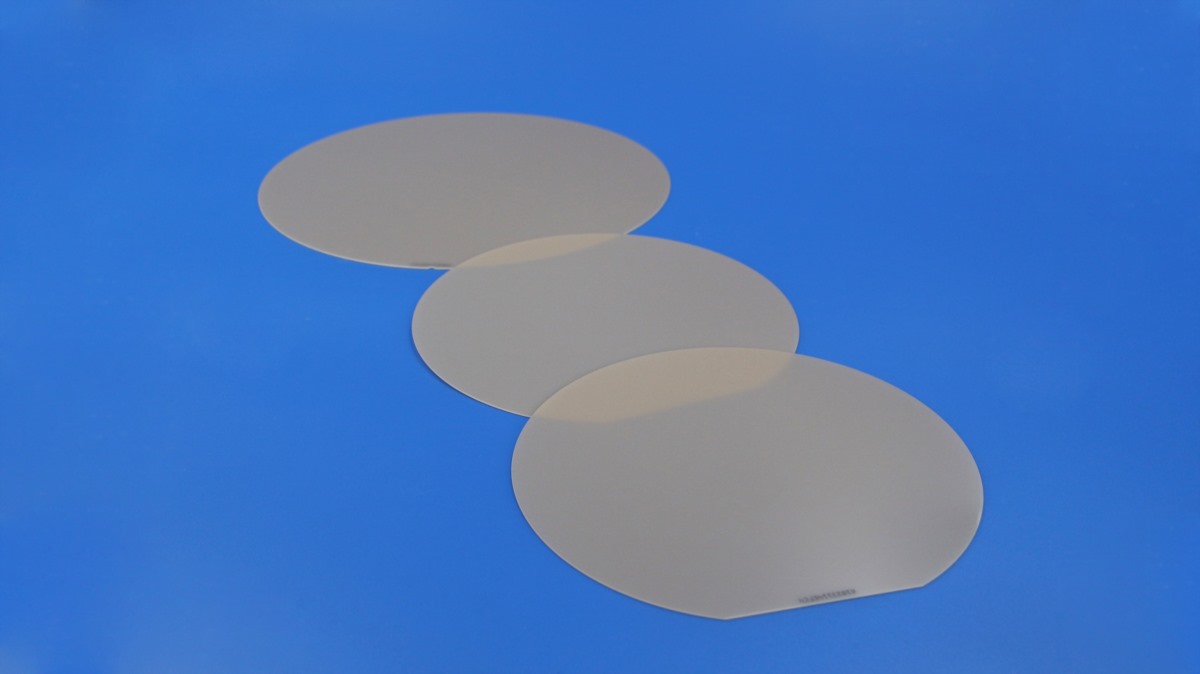

Aluminum Nitride Wafer Substrates play an essential role in the semiconductor industry. One of the key reasons for their popularity is their thermal profile, which closely matches that of silicon. This similarity makes AIN substrates an excellent choice for semiconductor applications where thermal management is critical. Innovacera, a leading provider of these substrates, offers Aluminum Nitride Wafer Substrates in various diameters, ranging from 2 inches to 8 inches, with the 6-inch and 8-inch sizes being the most commonly used.

Key Features of Aluminum Nitride (AIN)

Aluminum Nitride (AIN) stands out due to its impressive properties, which make it highly suitable for advanced semiconductor applications. Some of the most notable features include:

High Thermal Conductivity: AIN boasts a thermal conductivity range of 170-220 W/mK, which is crucial for dissipating heat in high-performance semiconductor devices.

High Electrical Insulation: The material’s excellent electrical insulation properties make it ideal for use in electronic components that require isolation from electrical interference.

Low Dielectric Constant: With a low dielectric constant, AIN substrates ensure minimal signal distortion, which is vital for maintaining the integrity of high-frequency signals in electronic circuits.

Mechanical Strength and Stability: AIN offers superior mechanical strength and stability, making it resistant to wear and deformation. This ensures the longevity and reliability of devices built on these substrates.

Corrosion Resistance: Aluminum Nitride demonstrates excellent resistance to corrosion, particularly against molten metals, enhancing its durability in harsh environments.

Chemical and Thermal Stability: The chemical and thermal stability of AIN substrates makes them reliable under extreme conditions, preventing degradation over time.

Applications in the Semiconductor Industry

The unique properties of Aluminum Nitride Wafer Substrates make them highly sought after in various semiconductor applications. These substrates are particularly valued in:

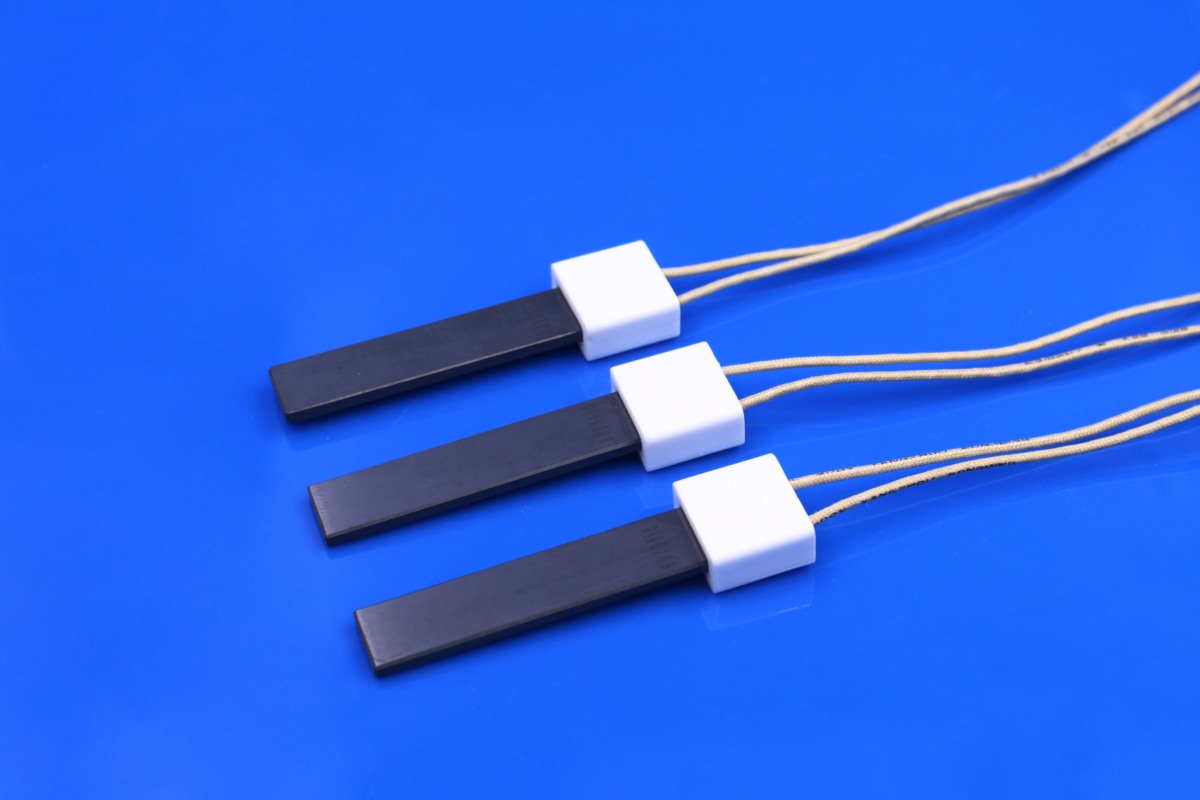

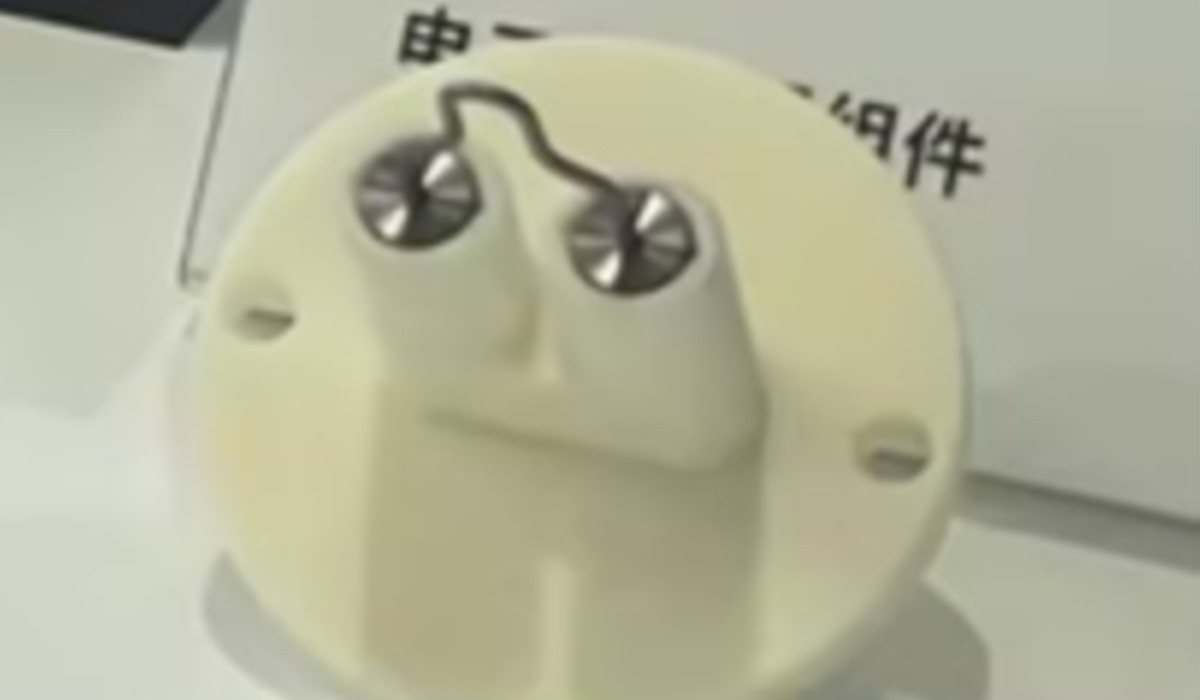

Power Electronics: The high thermal conductivity and electrical insulation of AIN substrates are crucial in power electronic devices, where efficient heat dissipation and electrical isolation are required.

RF and Microwave Devices: AIN’s low dielectric constant and excellent thermal properties make it an ideal choice for RF (Radio Frequency) and microwave devices, where signal integrity and thermal management are paramount.

LED Manufacturing: In LED applications, AIN substrates help manage the significant heat generated, thereby enhancing the longevity and performance of the LEDs.

Wafer Bonding Technology: Innovacera’s AIN wafers, with their polished surfaces (Ra ≤ 0.05 µm), meet the stringent requirements of direct wafer bonding technology. This process, which bonds semiconductor wafers without adhesives, demands extremely flat and smooth surfaces, and AIN substrates deliver on these fronts.

Aluminum Nitride Wafer Substrates are indispensable in the modern semiconductor industry, offering a combination of thermal conductivity, electrical insulation, and mechanical strength that few materials can match. Innovacera’s range of Aluminum Nitride (AIN) wafers, available in various sizes and customized options, provide the reliability and performance necessary for high-demand applications. As the semiconductor industry continues to advance, the role of AIN substrates will only become more critical, ensuring that devices remain efficient, durable, and capable of meeting the ever-growing demands of technology.

Choosing Aluminum Nitride Wafer Substrates can significantly enhance the performance and longevity of semiconductor devices, making them an excellent investment for any high-tech application.

Enquiry

Enquiry