Ceramic Components for Semiconductor Processing

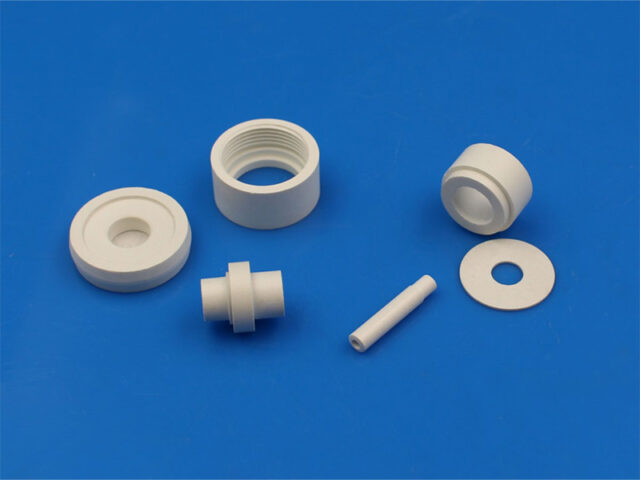

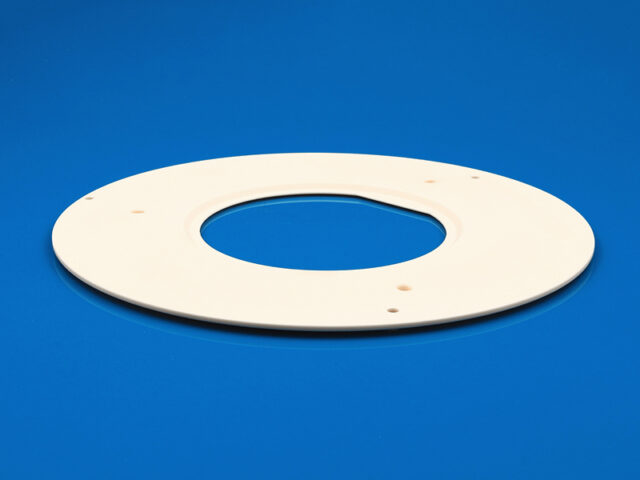

Engineered technical ceramics are widely used in semiconductor manufacturing processes due to their high temperature stability, electrical insulation, corrosion resistance, and excellent mechanical properties. INNOVACERA ultra-pure ceramics are used in the whole cycle of the semiconductor manufacturing process, including wafer manufacturing, device manufacturing, and packaging.

Device Manufacturing Process Etching

- High electrical resistivity

- High thermal conductivity

- Mirror polished surface and high precision flatness

Deposition

- Acid, alkali, salt, and organic reagent resistant

- High purity

- With anisotropy in the mechanics, heat and electricity

- High insulation

- Aeid, alkali, salt and organic reagent resistant

- With anisotropy in the mechanics, heat and electricity

Iron Implantation

Lithography & Cleaning & Inspection

Wafer Manufacturing Process

- Acid, alkal, salt, and organic reagent resistar

- High purity

- With anisotropy in the mechanics, heat, and electricity

- High purity

- Electrical insulator

- Reduced Particulate Generation

- Controlled Electrical Properties

Packaging Process

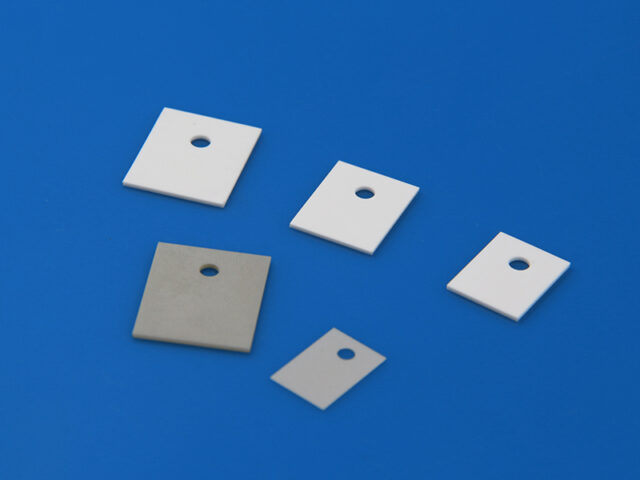

- Materials: Alumina / AlN / SiN

- Minimal deformation

- High thermal conductivity

- Stable insulation

- Resistance the acid and alkali corrosion resistance

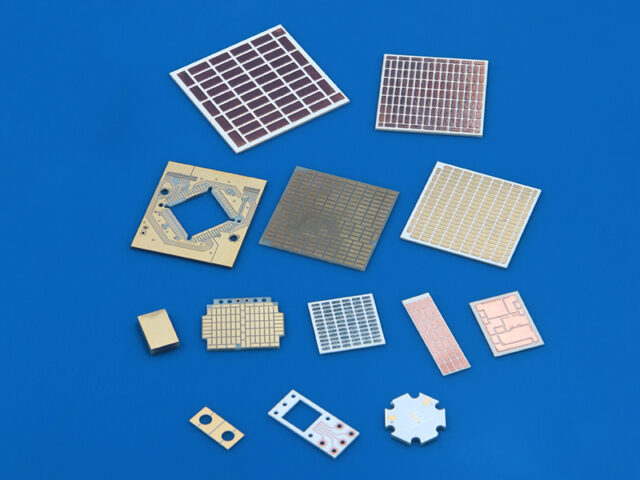

- Ceramie Materials: 95%, 9gi Alumina, AN, Be0

- Excellent sealing and bond strength

- Minimal substrate deformaticn

- Universal applicability for ceramic metal joining

- Uniform coating, thickness and density

- High thermal conductivity

- Low thermal expansion

- High bonding strength

- High wettabilty for solde

What role does ceramics play in the semiconductor industry?

Semiconductor chips are ubiquitous in modern technology. They are essential in the evolution of various electronic devices and systems, including smartphones, smartwatches, computers, automobiles, big data, cloud computing, and the Internet of Things (IoT). Semiconductor equipment comprises thousands of components, whose performance, quality, and precision directly influence the reliability and stability of the equipment. Consequently, a significant amount of precision ceramic parts is required in semiconductor equipment.

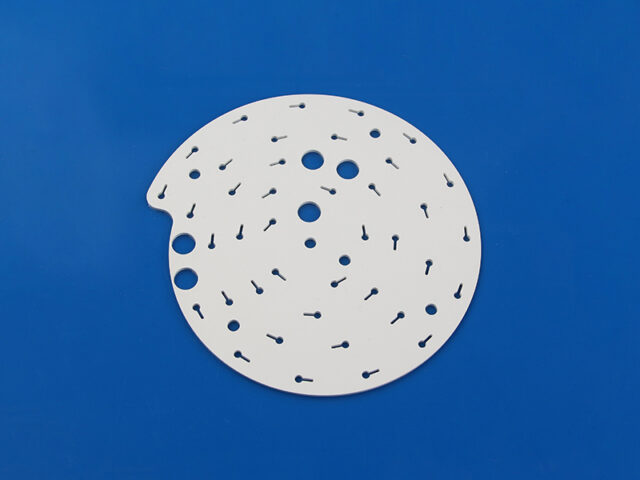

The ceramic parts we produce are reliable and durable. As long as you provide the drawings, our professional team can customize exclusive discs for you. Please be sure to choose INNOVACERA !

Related Videos

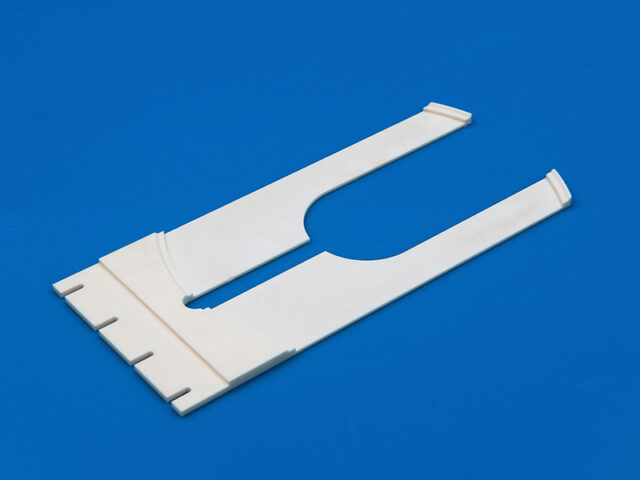

Alumina End Effector

Alumina ceramic handing arm end effectors are applicable to semiconductor and wafer equipment.Prevents static electricity and contamination when handling sensitive electronic components, ensuring their safety.

- High Hardness

- Good Wear Resistance

- Excellent Heat Resistance

- Excellent Insulation

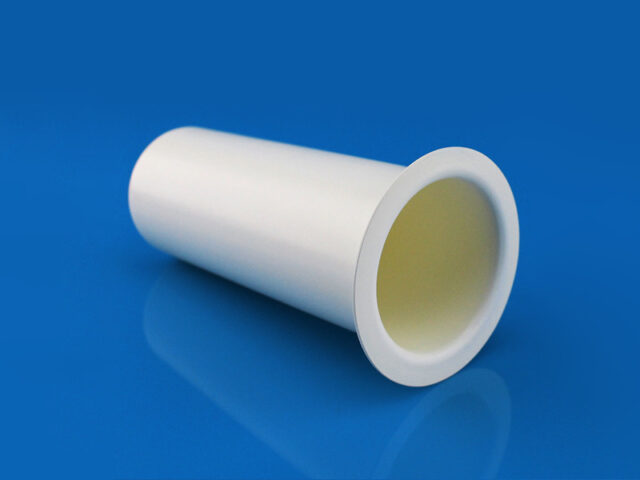

Ceramic Components for Semiconductor Processing

Engineered technical ceramic are widely used in semiconductor manufacturing proesses due to their high temperature stability,electrical insulation, corrosion resistance,and excellent mechanical properties. INNOVACERA ultra-pure ceramics are used in the whole cycle of the semiconductor manufacturing process,including wafer manufacturing,device manufacturing and packaging.

- High electrical resistivity

- Low thermal expansion

- High plasma durability

- Excellent electrical insulation properties

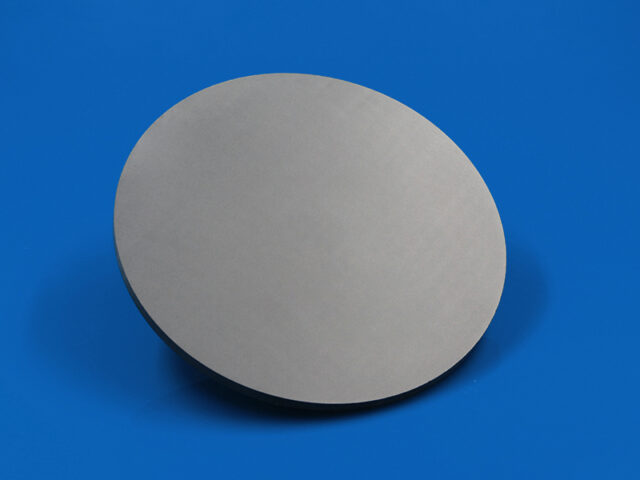

Aluminum Nitride Wafer

Aluminum Nitride Wafer Substrates are a crucial component in the semiconductor industry, known for their exceptional thermal and electrical properties. Aluminum Nitride (AIN) materials have gained prominence due to their compatibility with silicon, making them ideal for a variety of wafer-related applications.

- High melting point

- High electrical insulation

- Low dielectric constant

- Higher mechanical strength

- Superior corrosion resistance against molten metal

Enquiry

Enquiry