Boron Nitride Atomizer Nozzle For Aluminum Powder Metal Gas Atomization

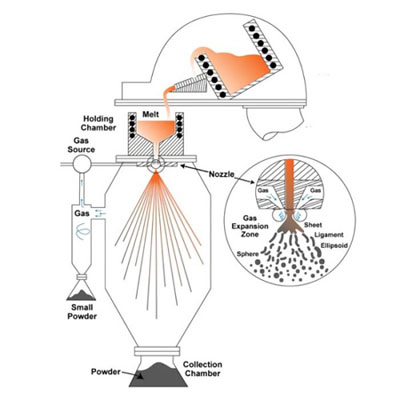

Powder metallurgy is one of the fast-growing sectors in the metal processing industry. And key quality parameters in the manufacturing of sophisticated powder metals are high atomization yield and tight particle size distribution.

The boron nitride nozzle is the key component of gas atomization, which largely determines the atomization rate, production efficiency and powder quality. But the nozzles face harsh conditions such as erosion, wear, high temperature, and severe thermal shock. In this case, its material determines the process stability and component life.

Boron Nitride Nozzle

Atomizer Nozzles made by Innovacera Boron Nitride minimize clogging and metal creep, reducing the frequency of nozzle replacement. Smooth surface finish and tighter tolerances thanks to the low coefficient of friction of boron nitride provide predictable particle size distribution from batch to batch. Additionally, extreme thermal shock resistance allows boron nitride nozzles to be used without extensive pre-heating.

Feature of boron nitride nozzles:

>Good resistance to thermal shocks

>Good resistance to high temperature in vacuum & gas protection condition

>Will not react with molten metals

>Non-wetting with molten metals and the nozzles will not be stuck

>Low thermal expansion coefficient

Innovacera’s engineers are constantly exploring the improvement of nozzles, and we develops a variety of material formula for boron nitride nozzles according to various gas atomization processes and powder materials to meet the needs of different users, we will give suggestion for material selection when inquiry.

Boron Nitride Atomizer Nozzle

Enquiry

Enquiry