New 3D Printer Hot End – Ceramic Heating Core

What is the Difference Between the New Hot End and the Traditional Hot End?

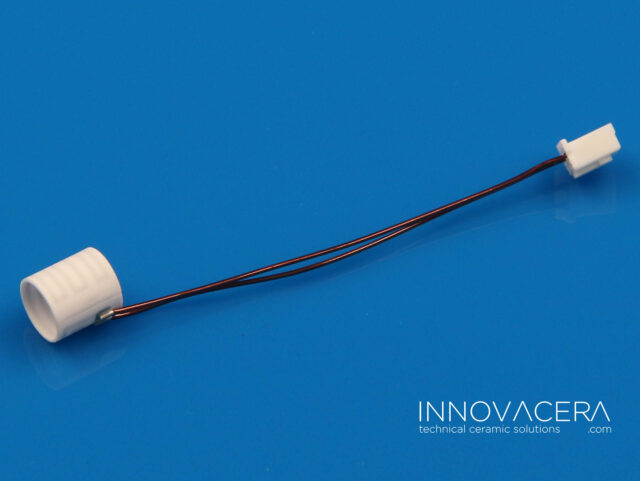

1. The new hot end consists of the nozzle, heating element, cold end (other parts of the extruder), and integrates the heater and thermistor. This design effectively solves the problems of traditional hot ends that cannot accurately control temperature and have low thermal efficiency.

2. Due to the ability to quickly replace the nozzle, when the nozzle is clogged or stuck, just replace it with a new nozzle. Each nozzle change reconnects with the filament, so printing can be resumed in minimal time. And since the nozzle and throat are integrated into one unit, there’s also no chance of material leakage.

3. The weight and volume are reduced, so the print head takes up less space, thereby improving printing accuracy and speed.

4. Use a new heater. The heating element is smaller and faster than traditional heating blocks, and has a positive temperature coefficient (PTC) that reduces power as heat increases, preventing overheating and burning, which can cause fires.

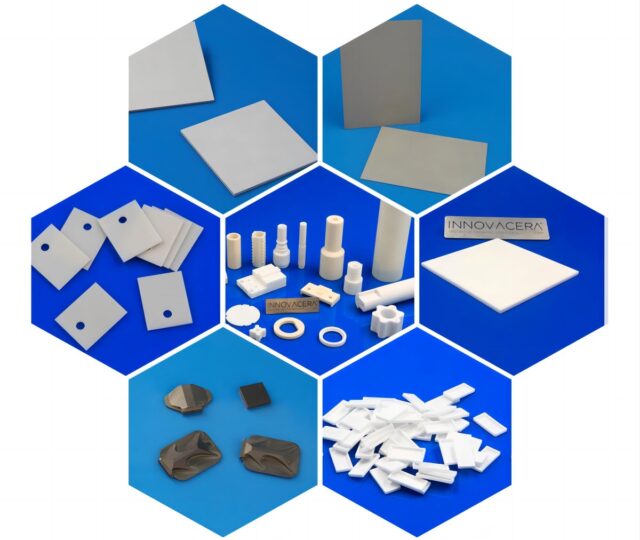

What is a Ceramic Heating Core? What is the Difference From Traditional Heating Tubes?

Let’s first introduce the traditional hot end.

A traditional hot end consists of a nozzle screwed into an aluminum heating block that is heated by an inserted cylindrical single-head heating tube. The module also houses a removable thermistor for temperature measurement. Finally, a separate throat thermally isolates the hot end from the wire feed path, preventing it from melting on its way to the hot end. This method of heating is very inefficient and has many problems.

First, the traditional hot end is large and heavy, which affects printing accuracy and speed. If it is a direct extrusion system, the frequency of motor vibration will also be increased, further reducing accuracy and speed.

Second, there is an air gap between the heater block and the thermistor and heating tube, so effective heat transfer and accurate temperature control are not possible. This leads to the problem of being unable to print at different speeds and extrusion volumes without being able to quickly change the nozzle temperature to accommodate changing filament feed rates. This is something that all consumer printers have not yet solved.

What about the ceramic heating core?

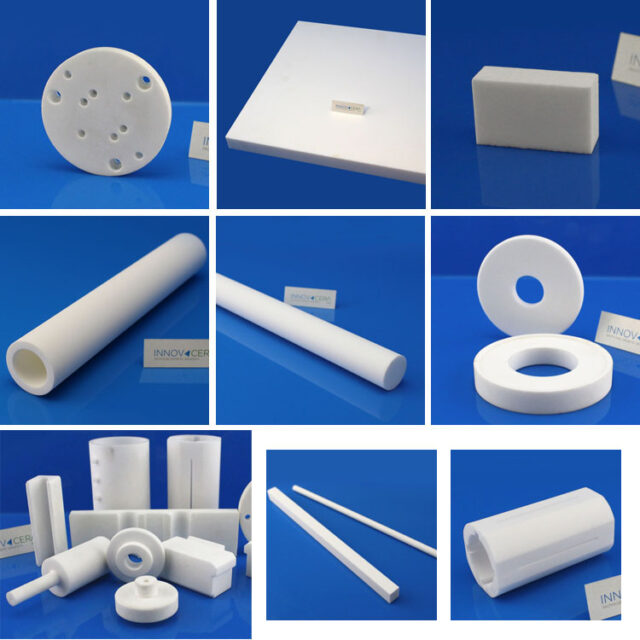

First of all, the application of ceramic heating core makes the hot end half lighter and smaller than traditional models. In other words, the ceramic heating core replaces the traditional heating tube, allowing the hot end to be designed to be lighter and more compact than the traditional one, thereby improving printing accuracy and speed.

Secondly, the ceramic heating core has a positive temperature coefficient (PTC), specifically, it reduces power when the temperature rises, thereby reducing the risk associated with temperature runaway when the maximum temperature is reached. At the same time, because the ceramic heating core can be integrated with the thermistor, precise temperature control can be achieved.

Finally, the ceramic heating core has more uniform heating performance and thermal efficiency. To achieve the same heating performance as traditional heating tubes, ceramic heating cores may only require lower power.

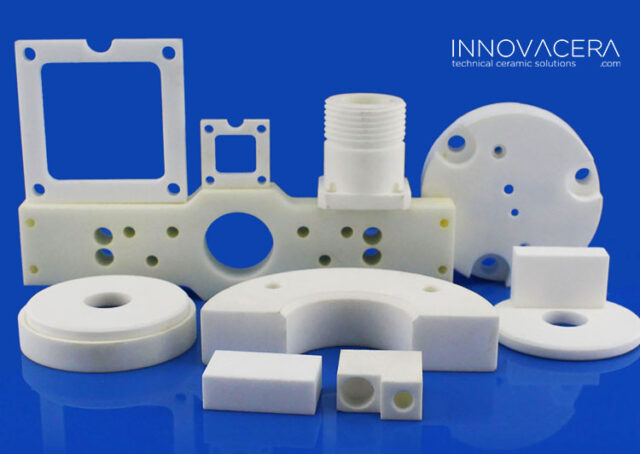

What is a Ceramic Heating Core?

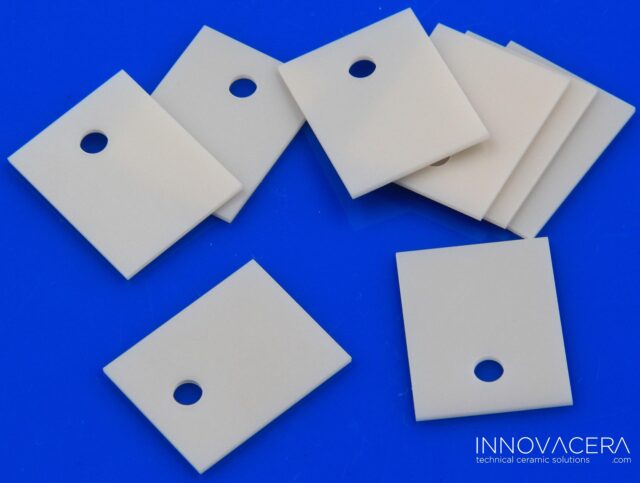

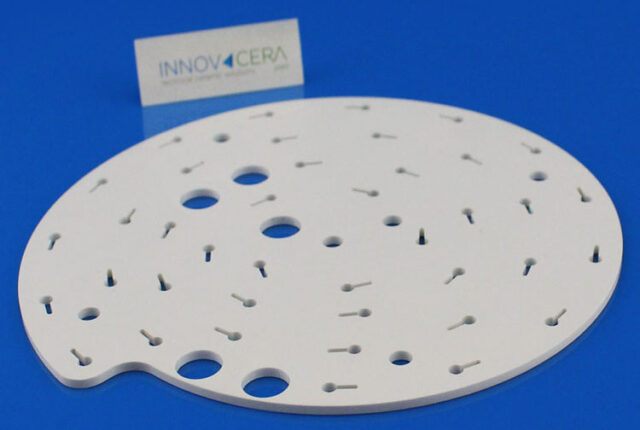

Ceramic heating core is a tubular ceramic heating element. It is a heating element made of alumina ceramics and metal heating resistor slurry sintered together.

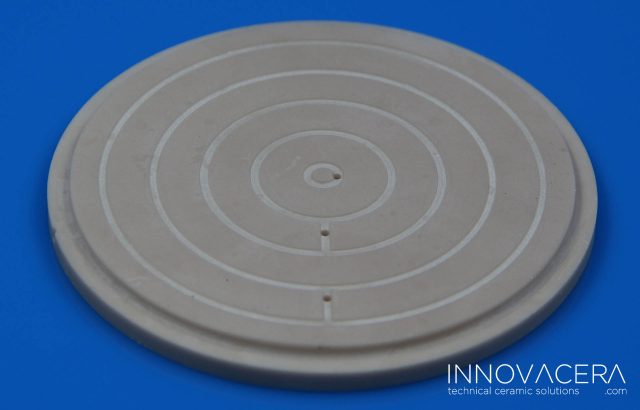

Main process: Print a circuit made of metal heating paste on an alumina ceramic green body with a composition of 92-96%. After hot pressing and lamination, it is jointly sintered in a reducing atmosphere at 1500-1600°C, so it is also called alumina ceramics. fever. Heating resistor slurry is made of tungsten and some precious metals, and its composition ratio affects the heating rate.

Features of ceramic heating:

1. Heating speed is fast. Several types of heating resistor slurries developed by our company can meet the requirements of heating up to 800°C in the fastest 10 seconds.

2. The heating temperature is high, and long-term use below 450°C does not affect the service life.

3. The heat is uniform and consistent, and the temperature difference at different locations in the heating area is small.

4. Thermal efficiency is high. On the premise of ensuring the heating speed, the power can be reduced to achieve the purpose of low energy consumption.

5. The surface insulation is uncharged and can be in direct contact with water.

6. The power density is high, so the volume can be reduced to less than 1cm³ without affecting the heating performance.

7. Safe and reliable, does not contain harmful heavy metals, and has passed RoHS, CE, FDA, ISO9001 and other qualification standards.

Enquiry

Enquiry