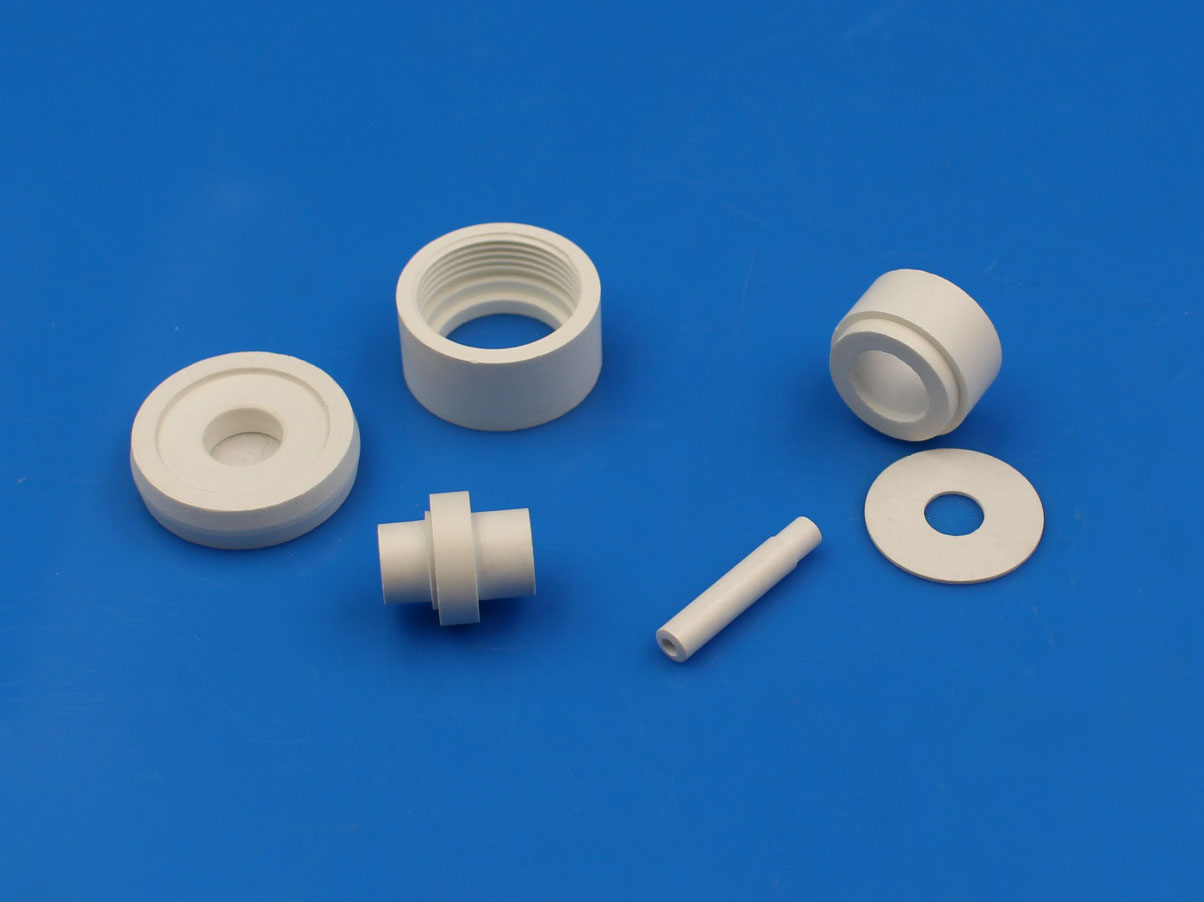

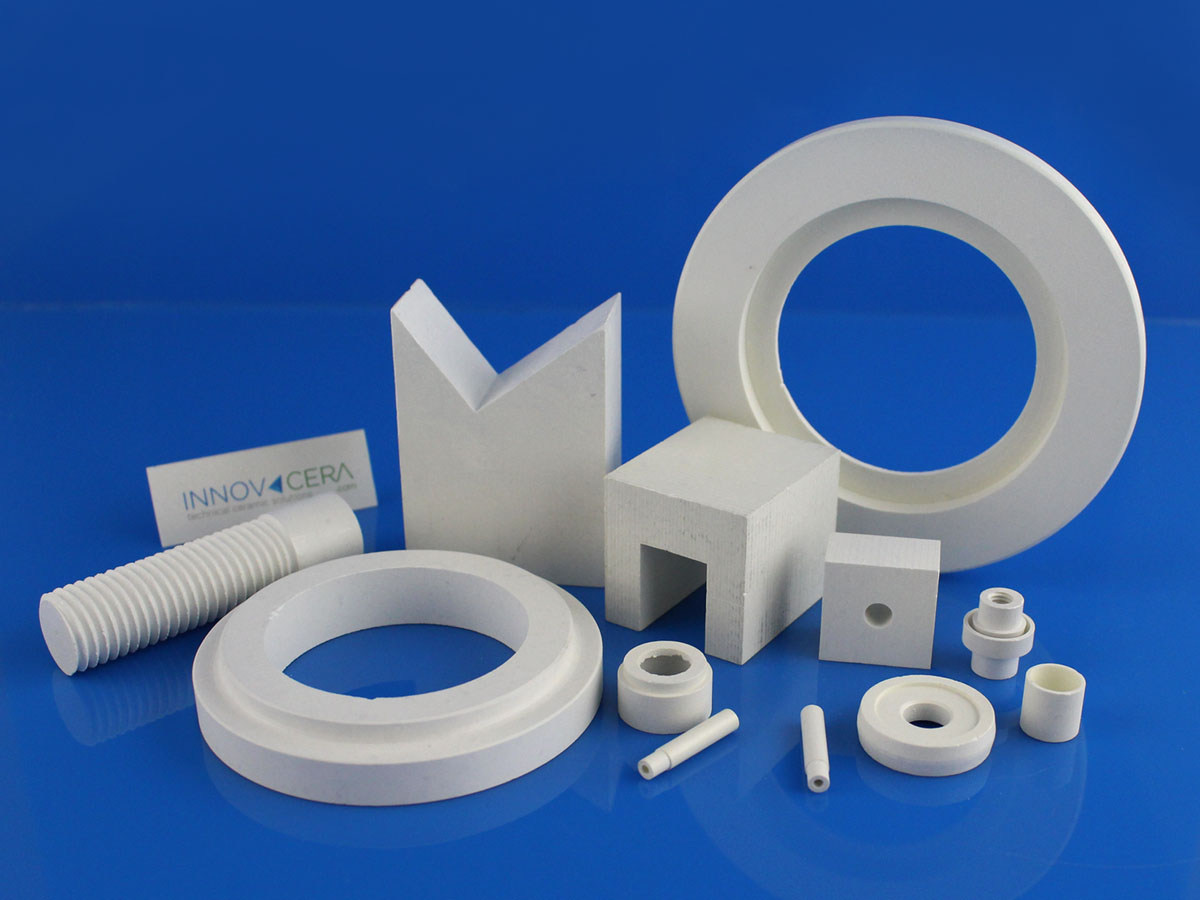

Machinable Glass Ceramic (also known as “Machinable ceramic”) is a polycrystalline composite material, white in its entire body. It is a glass ceramic material with synthetic mica crystallites as the main crystal phase. Machinable ceramic has high mechanical strength, excellent dielectric properties, thermal properties, and good chemical stability.

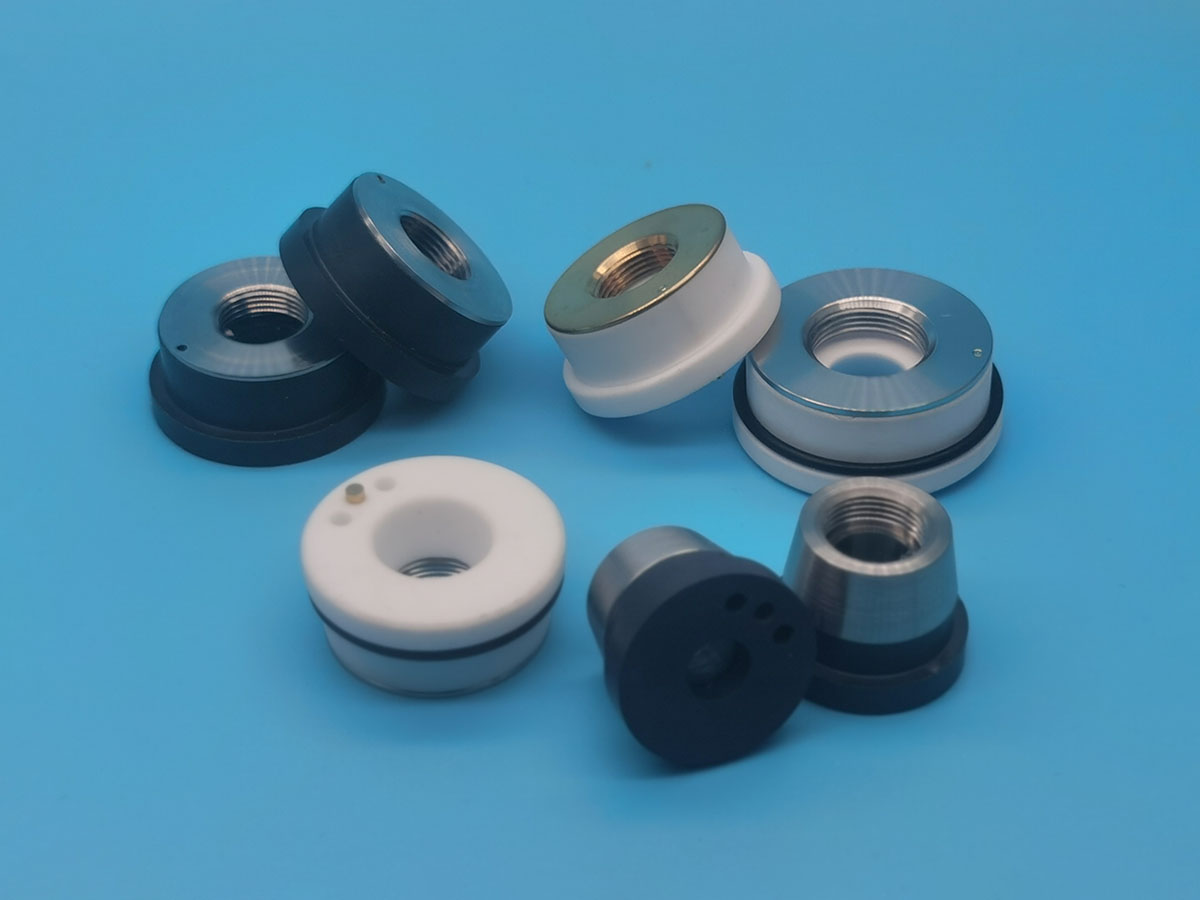

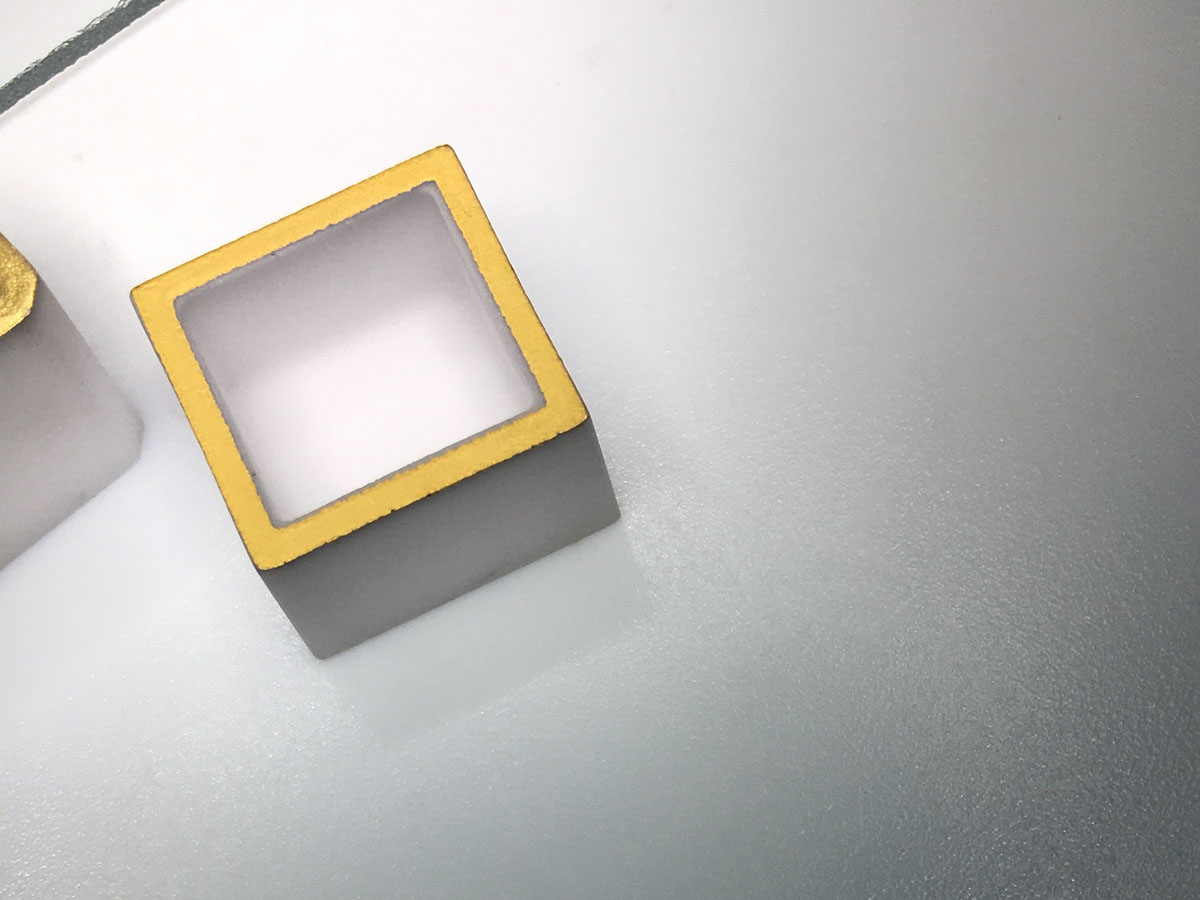

The most outstanding feature of machinable ceramics lies in its machinability, which can meet high-precision technical requirements, without making molds, and directly process and shape, which greatly reduces the design and processing cycle. Machinable ceramics can be flexibly applied to various structural ceramic parts that require complex shapes, high precision requirements, and difficult molding, such as various ceramic thin-walled, ceramic threads, and so on.

Machinable ceramics allow ceramic components to be made without the delay or expense of conventional ceramic manufacturing processes.

Applications of machinable ceramic include Aerospace Industry, Constant & Ultra-high Vacuum Environments, Medical Industry, Welding Nozzles, Semi-conductor Industry, and so on. Among those applications, the semi-conductor industry accounts for the largest market share, which was about 32.24% in 2016.

The machinable ceramic industry is relatively concentrated. Tokuyama is the largest producer with an output of 72389 Kg in 2016. The second producer, Corning, comes from France, with 28.08% output share.

Global production of machinable ceramic increased from 232517 Kg in 2012 to 238512 Kg in 2016. There is no doubt that Japan is the largest production base. As for consumption, the USA is the largest consumer with about 27.12% share in 2016. Europe is the follower, consuming about 53727 Kg.

Due to its own advantages, the machinable ceramic industry keeps an upward tendency in recent years, it is estimated that the global machinable ceramic industry will be worth 152.83 million USD in 2022.

Enquiry

Enquiry