Time : June 7-9, 2017

Address: Shanghai New International Expo Centre (SNIEC)

2345 Long Yang Road, Pudong Area, Shanghai, 201204, China

Organizer: Shanghai Time & Space Expo Co., Ltd

Website: http://www.sicchina.net/

Brief Introduce:

SIC China 2017 – The 9th Shanghai International Industrial Ceramics Expo, as one of the most important events in international industrial ceramics industry, will take place on 7-9 June 2017 at Shanghai New International Expo Centre (SNIEC), China.

With the rapid development of economy, industrial ceramics is widely used for mechanical equipment, gas appliances, communications, electronic devices, automobiles, motorcycles, textiles, environmental protection, water treatment, medical instruments, etc. The application scope of high-tech ceramics is extending, and the demand for new materials promotes the development of the industrial sectors, and further accelerates the development of industrial ceramics.

Exhibits Scope:

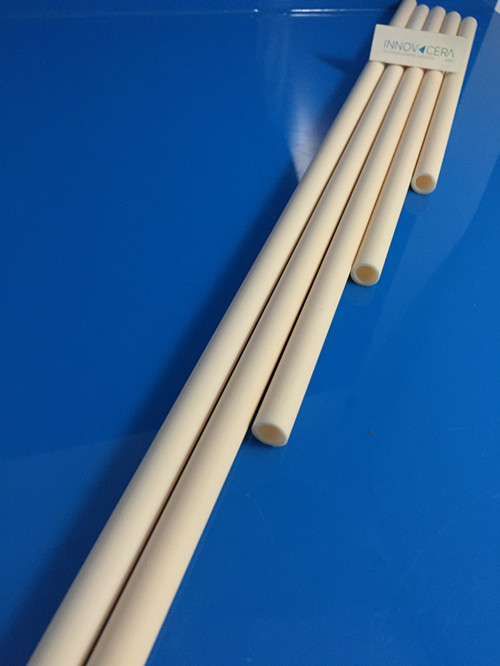

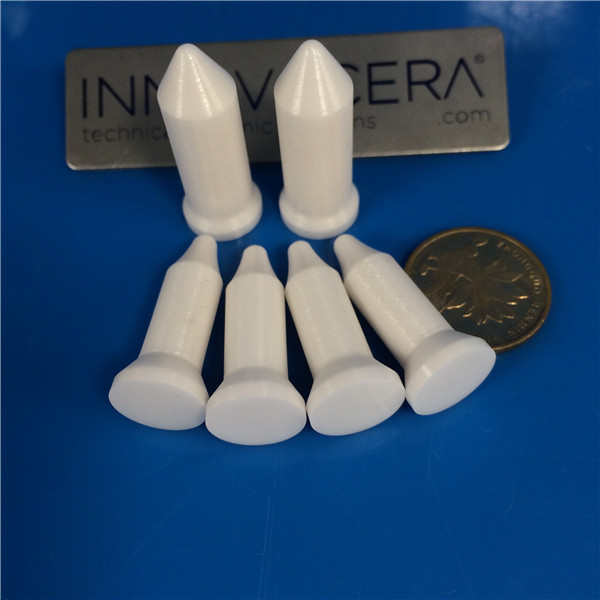

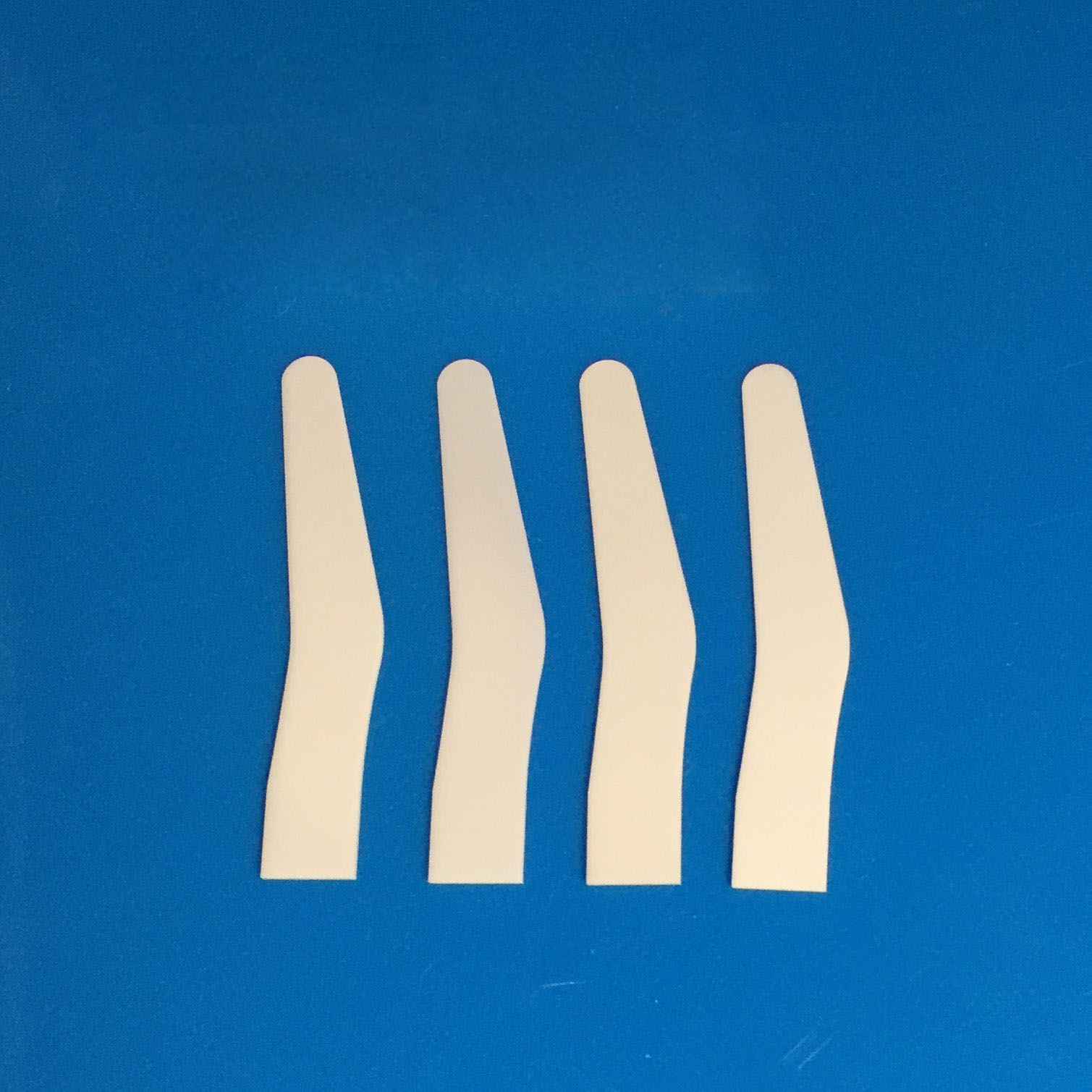

lndustrial Ceramics: fine ceramics, alumina ceramics, zirconia ceramics, high technical ceramics, electronic ceramics, functional ceramics, structural ceramics, abrasion resistant ceramics, carborundum ceramics, filter ceramics, high performance ceramics, ceramic fibre, ceramic seals, nano ceramics, honeycomb ceramics, oxide ceramics, nitride ceramics, porous ceramics, ceramic separation membrane, artificial crystal, fireproof materials, and biological and biochemical ceramics, oxide ceramic, non-oxide ceramic (carbide, nitrides, boride, silicides, etc.)

Electronic Components: functional sensor ceramic components of sorts, electrical ceramics, electric appliance ceramics, ceramic components of sorts, insulation device ceramics, capacitor ceramic, iron electrical ceramics, semiconductor ceramics, ion ceramics, insulation device ceramics etc.

Grinding Balls: ceramic ball, ceramic lining tile, plate, tower fillings and materials, new energy materials

Raw & Auxiliary Materials: natural and compound raw materials, oxide ceramic powder, non-oxide ceramic powder, raw material treatment techniques and equipment (crushing, grinding, mixing, weighing, palletizing and spray drying equipment), measuring equipment, etc.

Production Equipment: powder preparation equipment, product modeling equipment (dry granulation and semi-dry granulation modeling, isostatic pressing modeling, hot briquetting), reaction sintering, microwave sintering, etc.

Furnace & Apparatus Controlled Equipment: industrial furnace and apparatus controlled equipment (tunnel furnace, electric oven, atmosphere sintering furnace, microwave sintering furnace, small electric oven for lab purpose, new heating component, etc.) and other auxiliary equipment

Industrial ceramics-related new processes, techniques, materials, products and scientific research results.

Enquiry

Enquiry