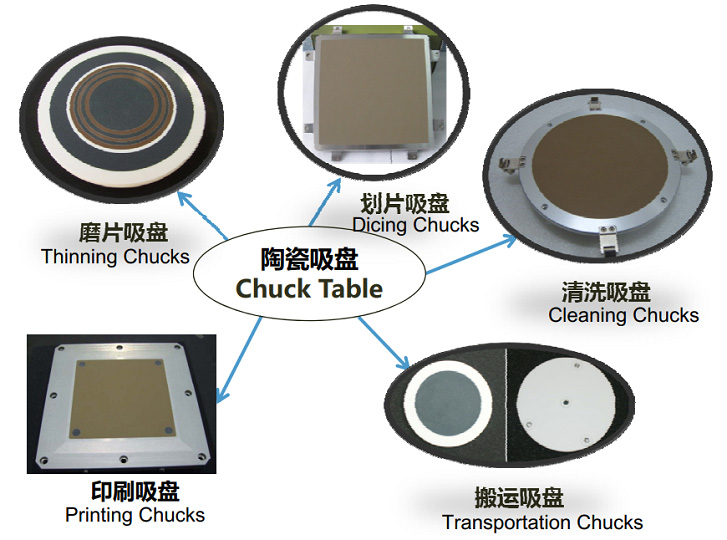

Aluminium nitride has become an important precision ceramic material because of its high thermal conductivity, high insulation resistance coefficient, excellent mechanical strength, and thermal shock resistance.

It is the ideal heat dissipation and packaging material for next-generation large-scale integrated circuits, semiconductor module circuits, and high-power devices.

Although the production capacity of aluminium nitride in China has reached a certain scale, the quality of aluminium nitride powder is not high. Some enterprises claim that the production capacity is put into production, but there is no actual output or low output.

With more domestic aluminium nitride powder projects put into operation and capacity utilisation increasing, it is expected that by 2020, China’s aluminium nitride powder output will increase to about 1,000 tons.

In recent years, with the rapid development of China’s electronics industry, the demand for aluminium nitride market has grown rapidly, with an average annual growth rate of 50%.

It is expected that the demand for aluminium nitride powder in China will maintain a growth rate of more than 30% in the next few years.

By 2020, China’s aluminium nitride market capacity is expected to reach 3,000 tons.

Enquiry

Enquiry