Alumina ceramic substrates for the automotive industry

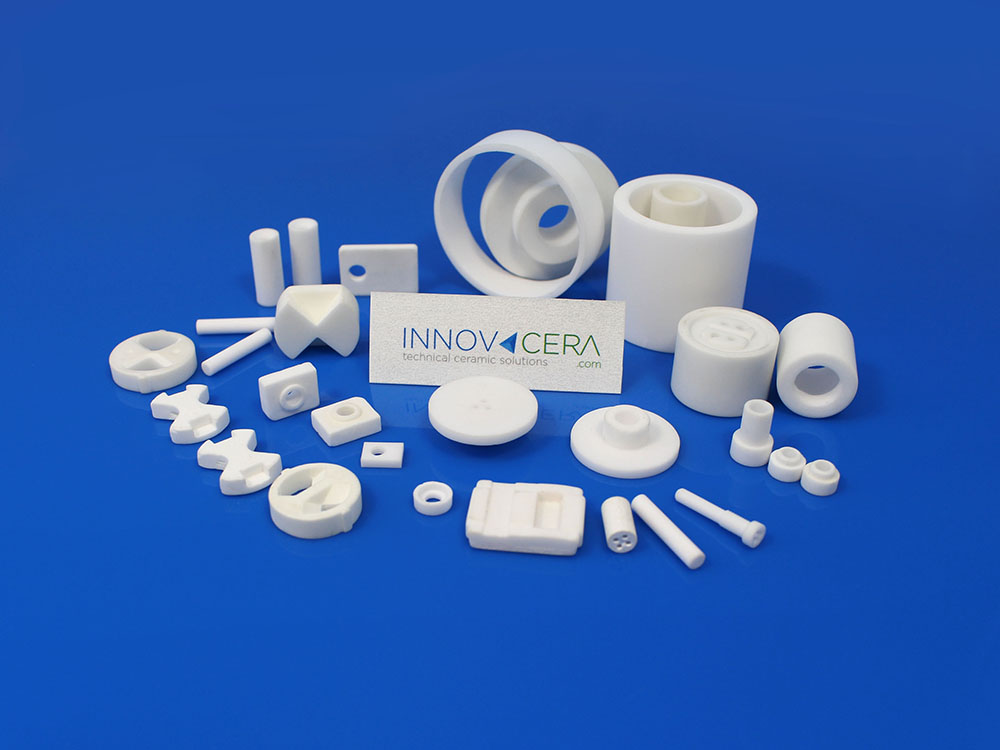

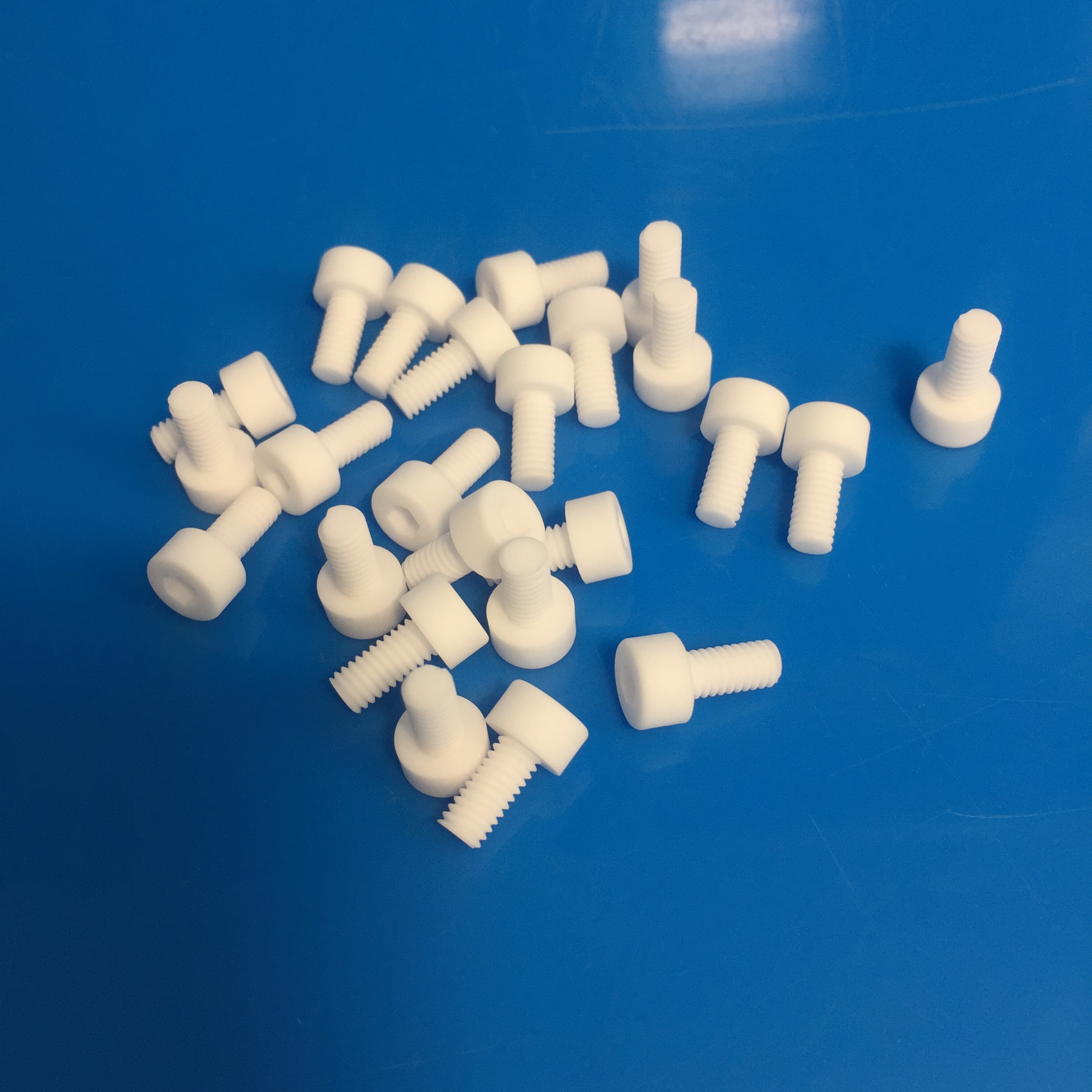

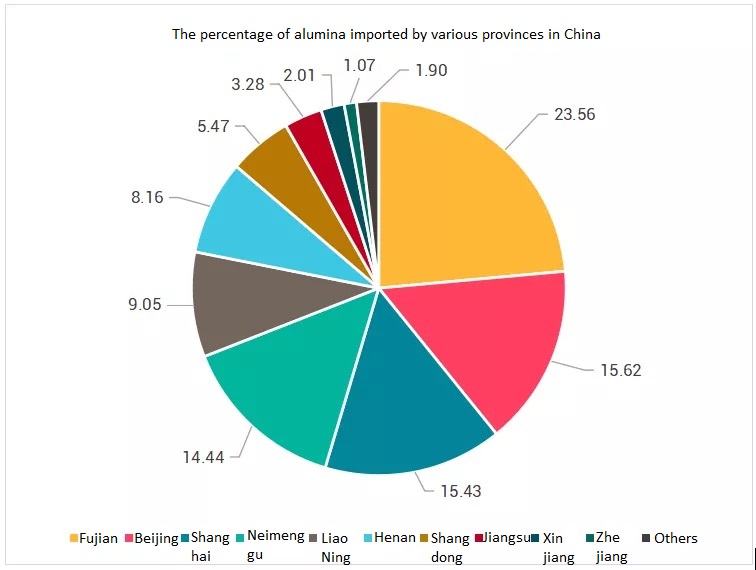

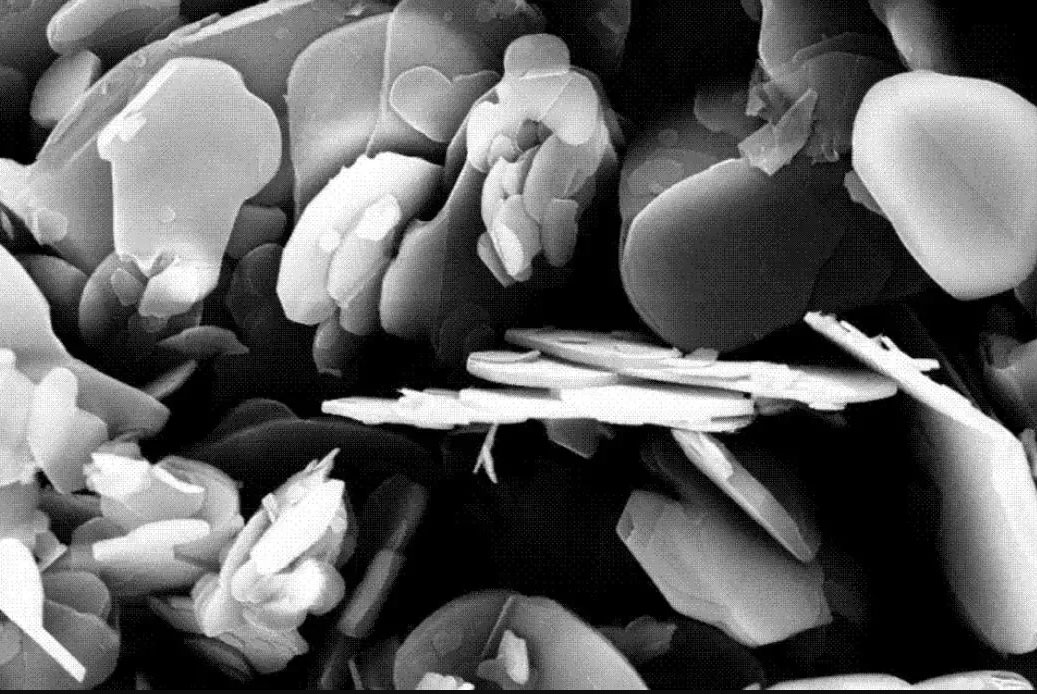

Alumina ceramics is a ceramic material with a-Al2O3 as the main crystalline phase. Because of its high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used under harsher conditions. Alumina ceramics have competitive prices and mature production technology. It is currently one of the ceramic materials with the largest output and the widest application range. It is mainly used in the fields of cutting tools, wear-resistant parts, and bio-ceramics. In addition, it is also widely used in energy, aerospace, chemical, chemical, and electronic fields. In particular, 95% and 99% alumina ceramic components, whether in structural ceramics or electronic ceramics, are some of the most widely used and most used ceramic materials.

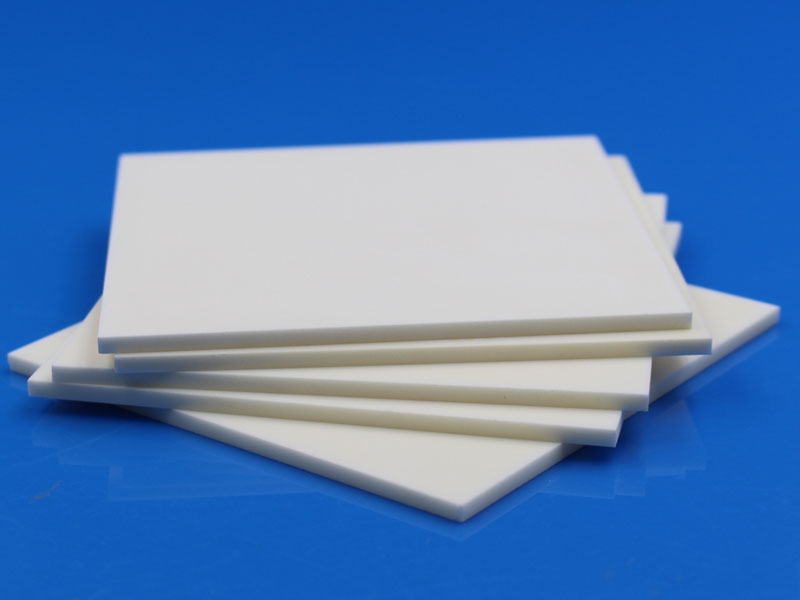

Such Alumina ceramic substrates now are widely used in the automotive industry, especially the large ceramic substrate. Innovacera are specializing in alumina ceramic substrates, the max size of AL2O3 ceramic substrates Innovacera made is 380*200*1 mm (0.8 mm and 0.635 mm thickness are also available). The substrates are part of a specific brazing process, used as spacers during thermal treatment.

PBN-PG-Heater-Element

PBN-PG-Heater-Element

Enquiry

Enquiry